Dongguan Kingrui Precision Mould Co.,LTD |

|

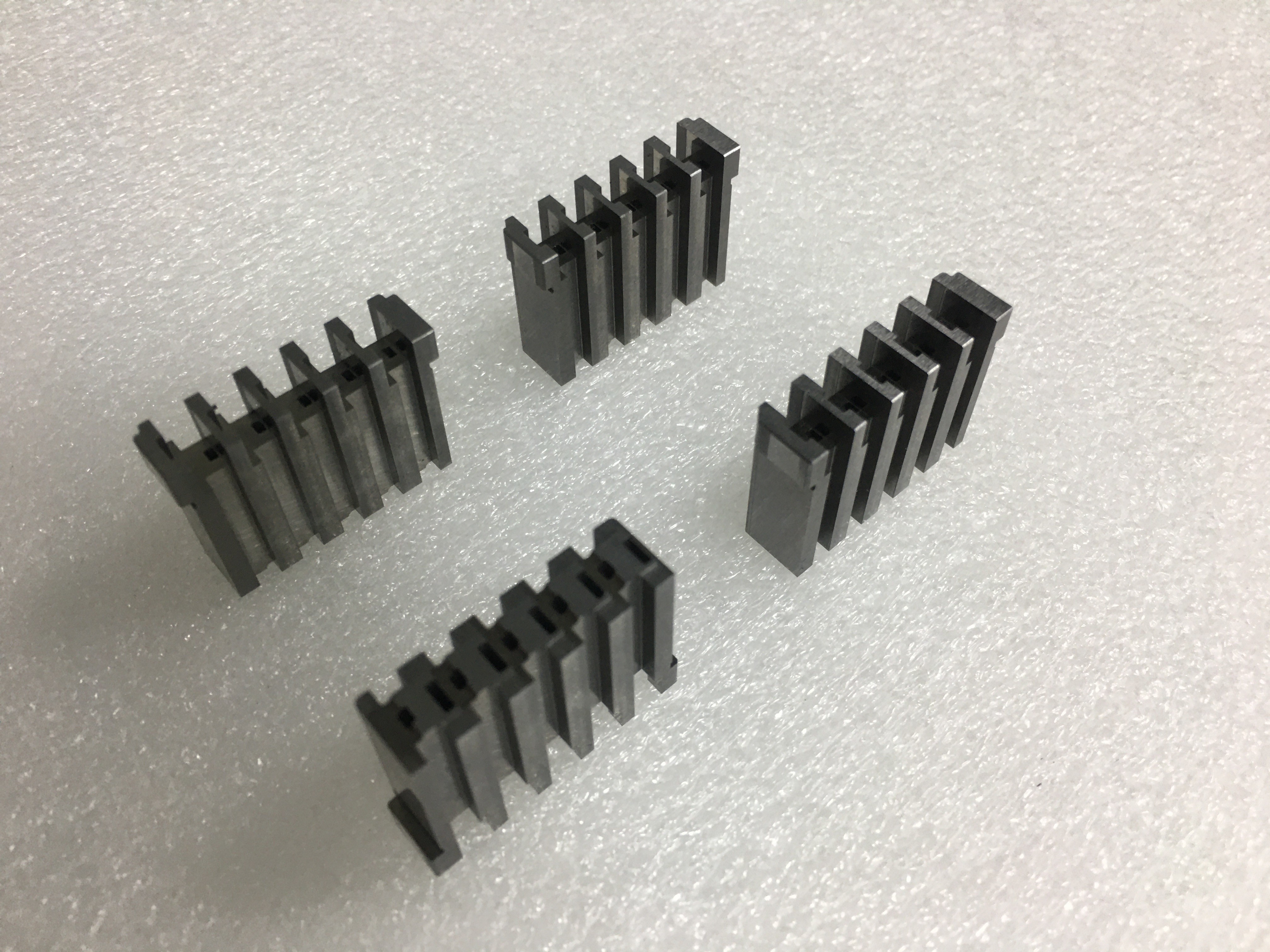

Wire EDM Wear Parts By Custom Precision Wire- EDM Parts Made for Sodick Wire Edm Parts

Chief Features

A. Surface: Surface grinding is done for this injection mold part.

B. Material: 635. And our factory can be available many other materials, See "Specification" below

C. Usage: Computer connector

D. Processing basis: According to customer's drawings

E. Manufacturing process: Grinding, EDM and WEDM.

F. Euipement: Plane grinder, Sodick EDM, wire EDM machines

G. Testing equipment: 2.5D projector, Japan Nikon Height Gages, two dimension, hardness meter and more.

H. Tolerance: +/-0.005 mm

Specification Over the Wire EDM Part

| Material | stainless steel / aluminum / brass / iron / zinc / Tungsten Carbide/ HSS etc

|

| Precision | ±0.005mm, as request

|

| Roundness | Within 0.001mm, as request

|

| Straightness | Within 0.002mm, as request

|

| Surface Roughness | Ra0.4, as request

|

| Manufacture Size | From 0.1mm to 6000mm or custom

|

| Hardness | HRC58+/-1°

|

| Standard | ISO

|

| MOQ | 1 Piece

|

| Website | www.Kingruimould.com

|

| Delivery way | DHL,UPS,EMS,FEDEX, as request

|

| Supply Capability | 1200-1500 pieces/ Month

|

Quality control in Kingrui

Good experience and technology in manufacturing mold parts, some

engineers have more than 16 years experience in producing

various kinds of precision parts, so could offer good technology

support to customers

Advanced measurement equipment to make sure all the requirement

from our customers will be measurable.100% inspection before

shipment.

(1). Incoming material inspection

(2). Inspection of work-in-progress

(3). Finished product inspection

All of our operations are strictly compliant with ISO 9001: 2008 guidelines

We own CNC machining, 2.5D projector, various height Gage and other testing equipment.

FAQ:

Q1: Are you a factory?

Yes,we are a factory.

Q3: Can i get some sample for check quality?

Usually, we don't provide free sample.

Q4: If i need the parts urgent, can you help?

Yes, we are here to help. Production time is flexible .If you need the parts urgent, please tell us the delivery time you need.We will do our best to adjust the production schedule priority.