Dongguan Kingrui Precision Mould Co.,LTD |

|

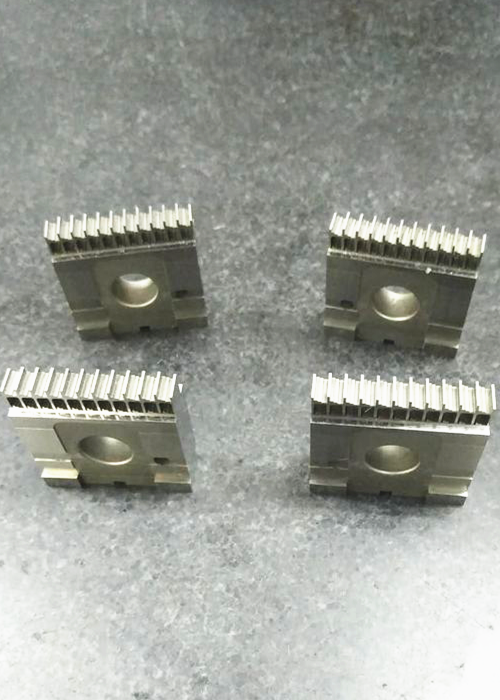

Precision Custom Injection Mold Components By Wire Cutting / EDM

Machining

B). Accuracy: Our common accuracy as follows:

More Feature and Specifications

(1). Quality assurance: ISO 9001: 2008.

(2). Material:

(3). Business Scope:

(4). Injection parts' surface treatment: Color painting, mirror

polishing, pvd coating, dlc coating, etc.

(5). OEM service is welcomed

(6). Practicable Software: Pro/ engineer, Solidworks, UG, Auto cad.

(8). Mold Making Time: 5- 15 working days

(9). List rendering:

| |

| Product Name | Injection mold Components |

| Working Process | Depends on your drawings' requirement. Kingrui is good at these

processes, such as: Surface grinding, EDM, wire EDM, Internal-

external lapping, CNC milling, and more |

| Material | Customized according to client's requirement. |

| Surface treatment | powder coating, polishing, pvd coating, dlc coating and so

on |

| Color | Red, blue, green, yellow |

| Packing | Inner- PE film, Plastic box; Outer - Standard Carton Box. |

| Usage | All kinds of cars, home appliance, electronic products, electric

appliance, computers, avaition , and more |

| Quality Control | Conducted by ISO9001: 2008 |

| Equipments | CNC, EDM, Milling Machine, WEDM, Internal- external lapping

machines,Grinding machines, 2.5D Projector, HG, and more. |

| File Format | Solidworks, Pro/ Engineer, Auto CAD, PDF, JPG |

| Service | Warm and quick response service provided by the professional Export

Sales Team with many years' experience in handling exports to the

US, Europe, Japan and other countries and regions. |

| Inspection | 100% inspection before shipment |