Shanghai Shengli Machinery Manufacture Co., Ltd. |

|

Horizontal Ribbon Mixer Machine , Double Ribbon Mixer Machine For Flour / Spice / Coffee

LHY horizontal ribbon mixer is widely used as chemical

blender, pharmaceuticals blender, food blender, and construction

material blender, spice blending machine,and dry powder blender

It can be used to mix powder with powder, powder with liquid, and

powder with granule.

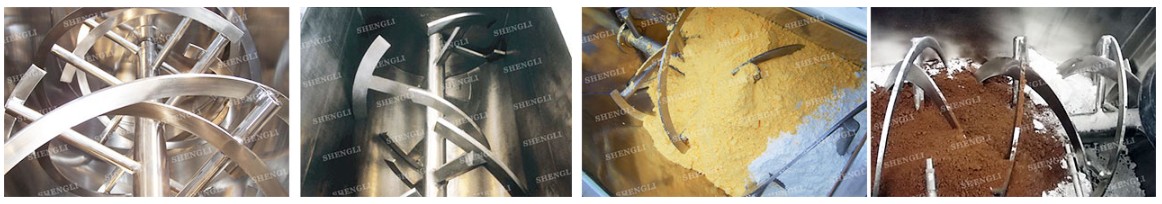

Under the driven of motor, the double ribbon agitator mix the

material quickly.

Working principle:

The outer ribbon push the material from the two ends to the centre,

inner ribbon push the material from center to the two ends.

Thus to achieve material convention

The discharging port is set in the bottom centre, with the help of

the outer ribbon,the material can be discharged completely, and no

dead zone.

Characteristic:

1, Fast mixing speed can satisfied the rigorous demand of mixing the materials with

different physical property.

2, The rotation is under critical speed, which will reduce the effect of fragmentation to

material e.g. crystal particle).

3, Lower height of the container is convenient for installation.

4, The positive and negative ribbons are set up at the same level, forming a mixing

environment of low power but high efficiency,

| specification | LHY-0.3 | LHY-0.5 | LHY-1 | LHY-2 | LHY-3 | LHY-4 | LHY-5 | LHY-6 | LHY-8 | LHY-10 | LHY-15 | LHY-20 | LHY-30 | |

| wrking capacity(m³) | 0.18 | 0.3 | 0.6 | 1.2 | 1.8 | 2.4 | 3 | 3.6 | 4.8 | 6 | 9 | 12 | 18 | |

| working capacity(kg) | 200 | 300 | 600 | 1200 | 1800 | 2500 | 3000 | 3600 | 4800 | 6000 | 9000 | 12000 | 15000 | |

| speed (r/min) | 62 | 62 | 49 | 33 | 33 | 27 | 27 | 27 | 22 | 14 | 14 | 14 | 12 | |

| power(kw) | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 110 | |

| weight | 600 | 900 | 1200 | 2000 | 2500 | 3500 | 4000 | 4500 | 5000 | 6000 | 7500 | 10500 | 13000 | |

| Length | 2280 | 2670 | 3140 | 3860 | 4460 | 4950 | 5280 | 5530 | 5100 | 5610 | 5820 | 6300 | 7000 | |

| width | 680 | 780 | 980 | 1200 | 1300 | 1400 | 1550 | 1560 | 1720 | 1750 | 2000 | 2350 | 2600 | |

| Height | 880 | 1240 | 1400 | 1650 | 1700 | 2000 | 2100 | 2200 | 2500 | 2650 | 2900 | 3160 | 3350 |

1. Flexible material selection

Material can be carbon steel, manganese steel, ss304, 316L and 321;

besides, different

material can also be used in combination. Surface treatment for

stainless steel include sandblasting, wiredrawing, polishing,

mirror polishing, all can be used in different parts of a mixer

2. The driven unit

Options for motor: general motors, explosion-proof motors, variable

frequency motor, high efficiency and energy saving motor.

Options of gearbox: R-series, K-series, and F-series gear box;

cycloidal reducer, universal gear reducer, planetary gear reducer.

Motor-gearbox connection: direct connection, pulley connection,

hydraulic coupler connection.

3. High efficiency mixing unit

Different main shaft agitators can be equipped according to the

properties of raw materials.

The main shaft agitator could be: inner and outer ribbon, paddle

and ribbon, disconnected ribbon, and shaver-shaped agitator.

4. Excellent discharging unit

The drive types of valve are Manual, pneumatic, and electric.

Valves for consideration: powder spherical valve, cylinder valve,

plum-blossom dislocation valve, butterfly valve, rotary valve etc.

5. Various inlets

Various inlets on the top cover of the barrel can be designed

according to different situations.

They can be used as man hole, cleaning door, feeding hole, vent,

and dust colleting hole.

The top cover can be designed as fully-opened lid for easy

cleaning.

6. Extra function

To realize the technicla of drying, cooling and keeping warm, the

mixer can be added a jacket structure out of the tank. Hot water or

steam or industrial oil can circulate int the jacket. Liquid

filling system can be installed at the top cover, the different

material of the atomized spray nozzle can realize the injecting of

acid or alkali liquid, or water.

The tank and the agitator can be coated with other material like

PE, PTFE, CARBIDE, etc. to realize the resistance of wear-out,

acid/alkali, or explosion etc.

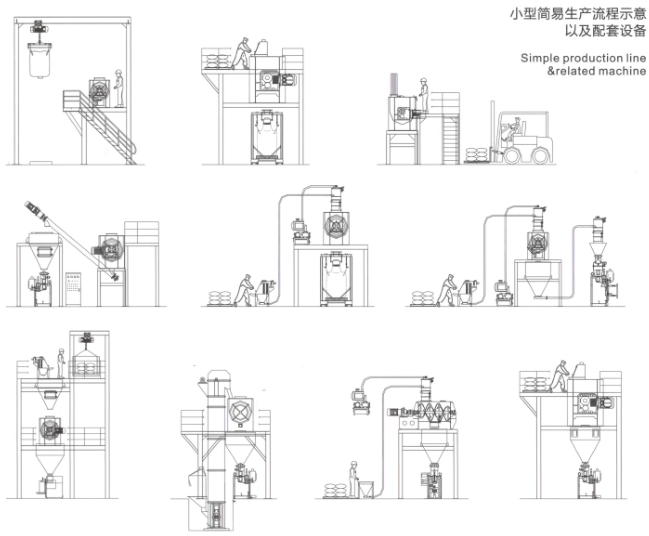

Simple system as dry ingredient blending machine like: food

blender, food additive mixer, milk powder blender easy

cleaning

Horizontal double ribbon mixing machine flour mixer, flavor

blender, spice blender, coffee blender