Kasmac Industries Co., Ltd. |

|

Delta Inverter With Stable Performance JH01-350/355 Tri-Color Advanced Drinking Straw Extrusion Line

Descriptions Of JH01-350/355 :

JH01 series drinking straw extrusion line is a set of drinking

straw production line, using polypropylene (PP) as raw materials,

with the use of master batch, after melting, extrusion, shaping,

cooling, pulling, cutting, then produce colorless, color,

two-color, three-color drink straw. With the mold, or other

auxiliary equipment, JH01 series is also suitable for extruding a

variety of tube similar to the drinking straw, and such of sheet in

small size, can be used with wide range of applications, for

example : drinking straws, lollipop sticks, coffee stirring stick,

ball-pen refill, cotton swab sticks, brake pipe and some pipe use

for the industry.

This production line is composed of extruder, die, cooling device,

traction and cutting device, electric control part, and so on.

Features :

Simple structure, high automation, easy and stable operation, and high efficiency.

The screw and barrel of extruder are made of 38CrMoLu high-quality alloy and have had a nitrogen treatment for a long service life.

For the reasons of drinking straws safety and having a nice appearance, water tank, hopper, etc. are made of 1Cr18Ni9Ti stainless steel.

Using inverter from Delta products a well-known brand, using conductor from Delixi, having smart temperature control units.

With output counting function, that can catch batch products alarm.

Optional Accessories For Drinking Straw Extrusion Line :

Vacuum forming device

Manual filter

Drinking straw collecting machine

| Main Technical Parameters | ||

| Model | JH01-350 | JH01-355 |

| Material | PP/PE | |

| Color | 1 color straw and 2 colors line | |

| Production dia. | Φ1-14 mm | Φ1-14 mm |

| Production length | 3-1000 mm | 3-1000 mm |

| Product capacity | Max. > 35kg/h | Max. > 45kg/h |

| Line speed | Max. >250 meter/min | Max. >250 meter/min |

| Main motor | VS 7.5kw by inverter control | VS 11kw by inverter control |

| Assistant motor | 2 xVS 0.75kw by inverter control | 2 xVS 0.75kw by inverter control |

| Heater capacity | 12 kw | 14 kw |

| Temperature control | 11 set | 11 set |

| Figuration and water-cool unit | 3.5 m (can choice 5m) | 3.5 m (can choice 5m) |

| Traction and cutting unit | 2 xVS 0.75kw by inverter control | 2 xVS 0.75kw by inverter control |

| Total power | 24 kw | 30 kw |

| Total power used | 15 kmh/h | 20 kmh/h |

| Weight | 1200 kg | 1400 kg |

| Dimension (LxW) | 10x2 m | 10x2 m |

Applications

Food industry : Drinking Straw, coffee stirring stick, lollipop sticks, candy floss sticks, ice cream bars, etc.

Industrial applications : cartridge, pen, spray straw, cotton swab stick, medical tubes, toys tube, threading pipe, tube, brake tubes and other small profile.

Irrigation System : Micro-drip irrigation pipe, etc.

Typical Capacity

Extruder

The main extruder’s screw designed to suit plastic material specified. Tube die head with die pin/bush assembly manufactured in tool steel. They are controlled by inverter.

Vacuum Calibration and Cooling

Water bath in stainless steel with full adjustment in three planes for accurate alignment With extrusion die. Fitted with venturi vacuum sizing unit with stainless steel vacuum chamber, reservoir tank and lid, circulating pump, and all necessary pipe work and controls.

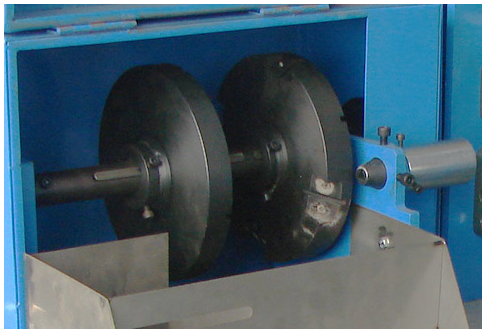

Haul-off

Caterpillar haul-off with linatex covered belt or haul-off with rollers, driven by motor with control for variable linear speed between 5 and 250 meters/minute or to suit customer’s requirements. This unit provides two functions for added choice straight or spiral stripes on the tubing surface. Inverter control.

Rotary Cutter

Fitted with either single or double rotary cutter, suitable for light duty applications driven by variable speed gearbox. Includes cutting and quick bushes with necessary guarding. Inverter control

Haul-off and Rotary Cutter

Hall-off is combined with rotary cutter