Kasmac Industries Co., Ltd. |

|

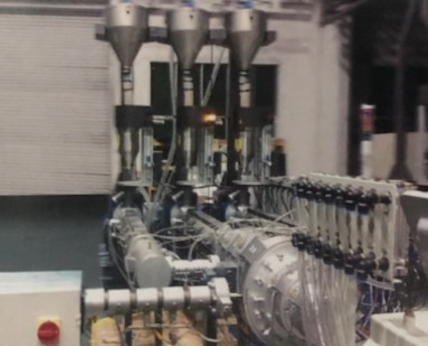

Descriptions :

| Main Technical Parameters | ||||

| Model | Pipe Spec | Extruder | Main Power | Output |

| Unit | mm | kw | kg/h | |

| JWPEG-75 | ⌀16-⌀75 | JWS-H65/33+45/25 | 45+15 | 105-155 |

| JWPEG-125 | ⌀20-⌀125 | JWS-H65/33+45/33 | 75+22 | 250-300 |

| JWPEG-160 | ⌀50-⌀160 | JWS-H65/33+45/33 | 75+22 | 250-305 |

| JWPEG-315 | ⌀75-⌀315 | JWS-H75/33+45/33 | 132+30 | 475-540 |

| JWPEG-500 | ⌀160-⌀500 | JWS-H90/33+65/33 | 160+75 | 700-790 |

| JWPEG-630 | ⌀315-⌀630 | JWS-H120/33+75/33 | 280+110 | 1200-1350 |

Other Pipe Line Assisting Parts :