Kasmac Industries Co., Ltd. |

|

Descriptions :

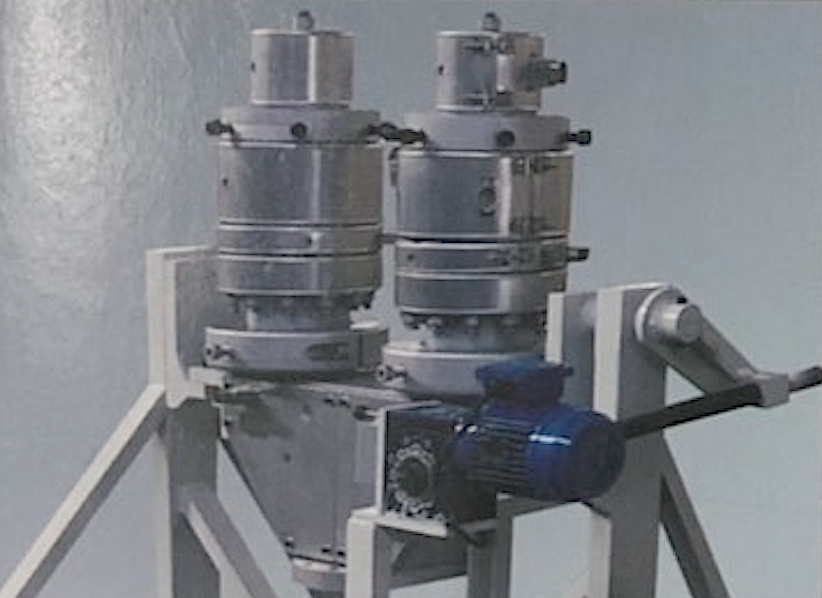

Corresponding to the different requirments of pipe diameter and output, there are two types of SJZ80 and SJZ65 special twin-screw extruders optional, the dual pipe die evenly distributes the material output and the pipe extrusion speed is quickly plasticized.

Equipped with high-efficiency double-vacuum cooling box can be controlled separately and the adjustment operation is convenient in the production process. Dustless cutting machinem double station independent control, fast speed, accurate cutting length. Pneumaticlly rotating clamps eliminates the need to change clamps. With chamfering device optional.

| Main Technical Parameters | |||||

| Model | Strand | Pipe Spec | Extruder | Main Power | Output |

| Unit | mm | kw | kg/h | ||

| JWG-PVC 63 | Two | ⌀16-⌀63 | SJZ65/132 | 37 | 250-300 |

| JWG-PVC 110 | Two | ⌀50-⌀110 | SJZ80/156 | 55 | 300-400 |

| JWG-PVC 200 | Two | ⌀50-⌀200 | SJZ80/173 | 75 | 400-500 |

Other Pipe Line Assisting Parts :