Share Group Limited |

|

Verified Suppliers

|

|

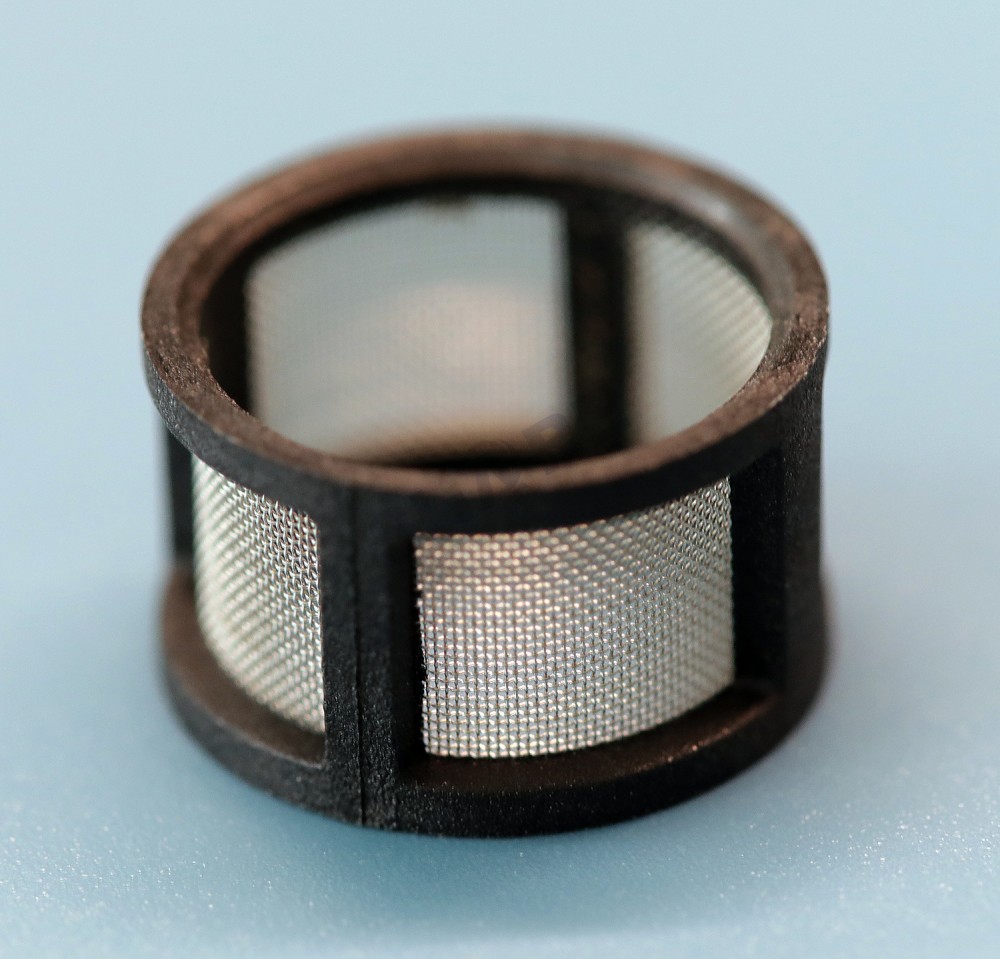

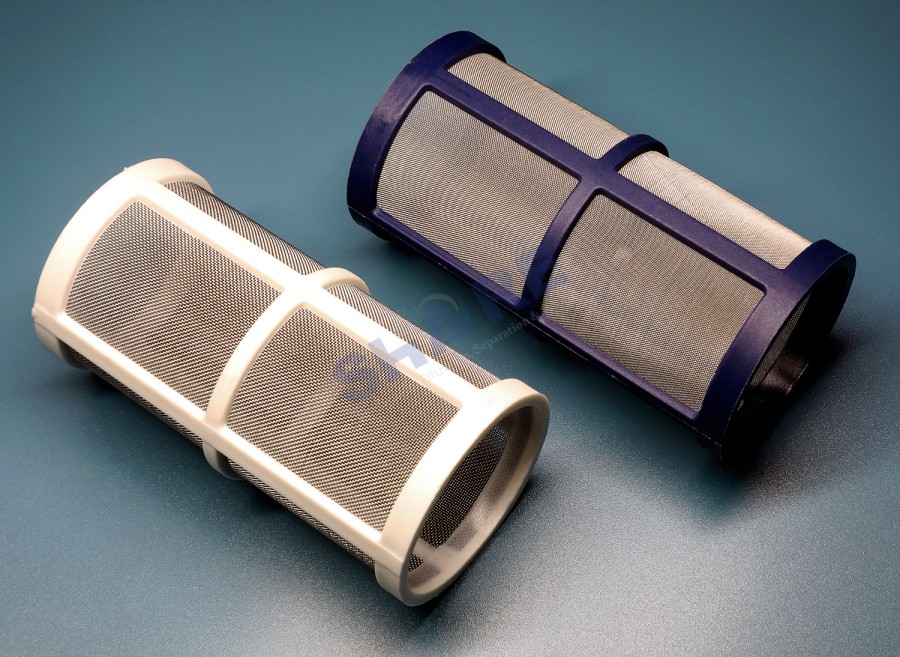

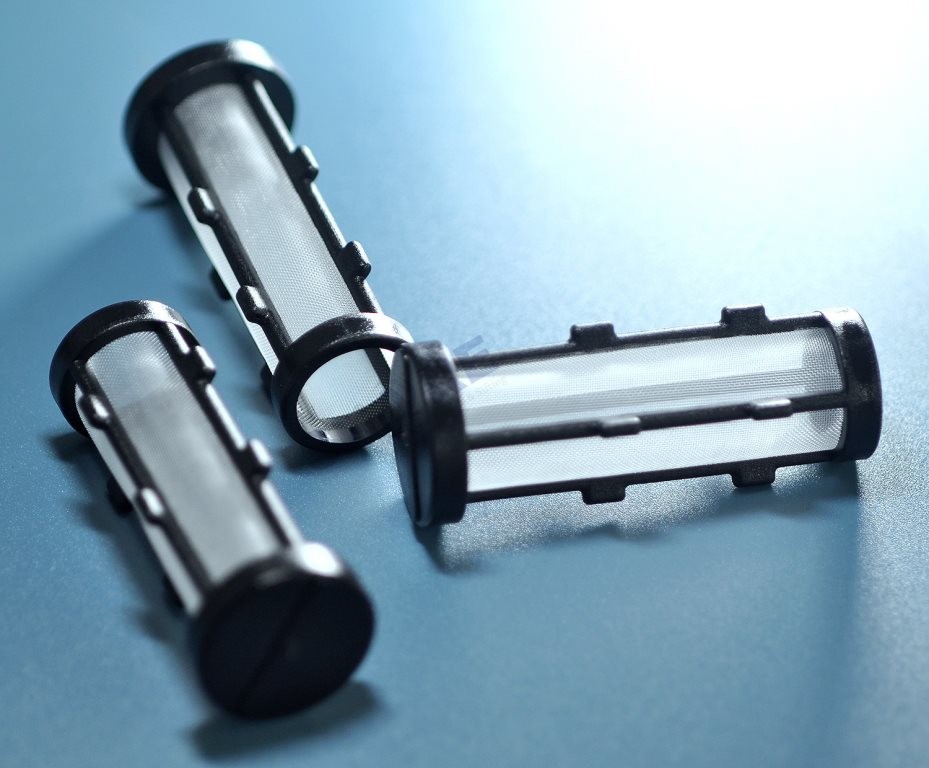

Suction Filter For Indirect Oil Fired Space Heater Nylon Mould Screen

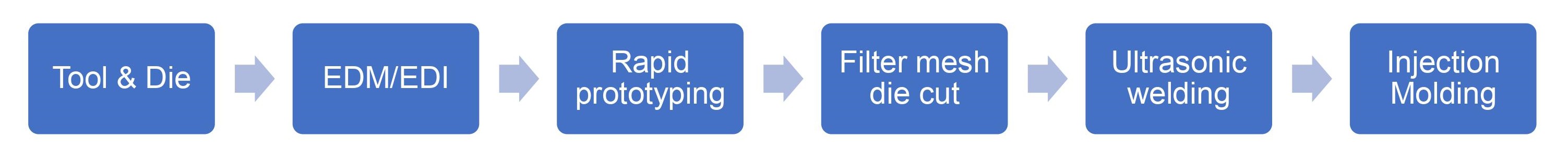

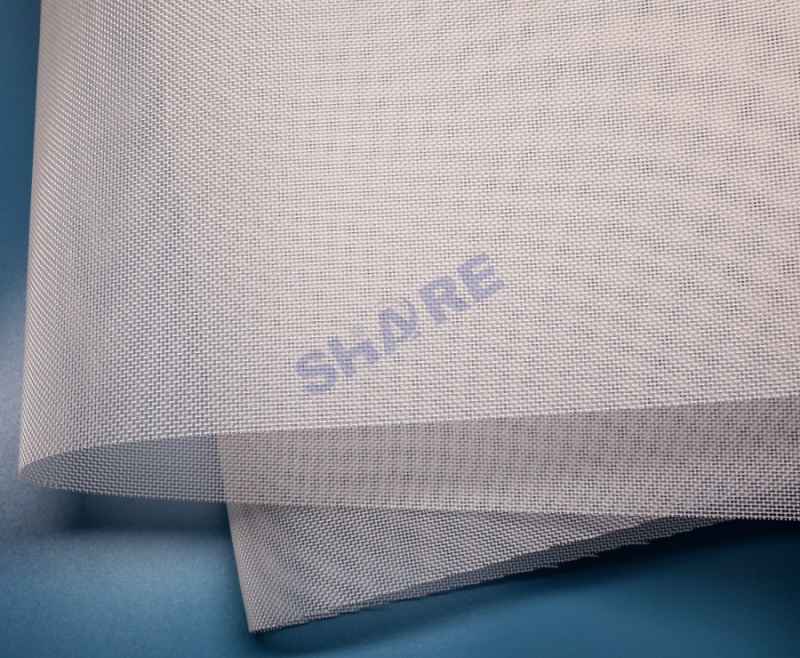

Share Filters' suction filter for indirect oil fired space heater combines the nylon or polyester filter mesh with thermoplastic, allowing for a more robust part giving more reliability and longevity in its use. Injection moulding can take many forms and Share Filters is fully capable to help develop and produce the injection moulded filter products according your drawing that will best suit your needs, as well as, offering any additional advice or service along the way.

Share Filters Suction Filter For Indirect Oil Fired Space Heater Material Options

| Support rim material | PA, PET, PP, PC ABS, PE, POM, etc. |

| Filter media | Nylon mesh, polyester mesh, PP mesh, metallic mesh | |

| Micron rating | 20μm - 200μm | |

| Mesh parts fabrication | Laser cutting, sonic cutting, sonic welding, heat welding |

| Process | Mesh insert injection moulding | |

| Specification | Custom | |

| Colour | Custom |

Nylon Filter Mesh Specification For Suction Filter For Indirect Oil Fired Space Heater

| Fabric number | Mest count | Thread diameter | Mesh opening | Open surface | Fabric thickness | Weight | |

| No. | mesh/cm | mesh/inch | micron | micron | % | micron | g/m2 |

| JPP30 | 30 | 76 | 120 | 213 | 41 | 225 | 94 |

| JPP32 | 32 | 80 | 100 | 213 | 46 | 165 | 69 |

| JPP36 | 36 | 90 | 100 | 178 | 41 | 178 | 78 |

| JPP40 | 40 | 100 | 100 | 150 | 36 | 190 | 87 |

| JPP43 | 43 | 110 | 80 | 152 | 43 | 135 | 60 |

| JPP48 | 48 | 120 | 80 | 130 | 38 | 145 | 62 |

| JPP56 | 56 | 140 | 60 | 120 | 44 | 85 | 44 |

| JPP59 | 59 | 150 | 60 | 110 | 42 | 98 | 46 |

| JPP64 | 64 | 160 | 60 | 100 | 37 | 105 | 50 |

| JPP72 | 72 | 180 | 50 | 90 | 41 | 82 | 39 |

| JPP80 | 80 | 200 | 50 | 75 | 36 | 90 | 43 |

| JPP100 | 100 | 250 | 42 | 60 | 36 | 65 | 35 |

| JPP120 | 120 | 305 | 30 | 55 | 42 | 52 | 20 |

| JPP120 | 120 | 305 | 35 | 45 | 29 | 60 | 28 |

| JPP120 | 120 | 305 | 38 | 42 | 25 | 67 | 35 |

| JPP120 | 120 | 305 | 42 | 42 | 25 | 75 | 42 |

| JPP130 | 130 | 330 | 30 | 47 | 37 | 55 | 22 |

| JPP130 | 130 | 330 | 35 | 42 | 30 | 62 | 30 |

| JPP130 | 130 | 330 | 38 | 40 | 26 | 74 | 36 |

| JPP140 | 140 | 355 | 30 | 38 | 28 | 53 | 25 |

| JPP140 | 140 | 355 | 35 | 37 | 26 | 65 | 33 |

| JPP140 | 140 | 355 | 38 | 32 | 20 | 68 | 36 |

| JPP145 | 145 | 368 | 38 | 30 | 19 | 64 | 40 |

| JPP150 | 150 | 380 | 30 | 34 | 26 | 50 | 26 |

| JPP150 | 150 | 380 | 38 | 31 | 21 | 68 | 40 |

| JPP165 | 165 | 420 | 30 | 30 | 25 | 59 | 28 |

| JPP165 | 165 | 420 | 38 | 25 | 15 | 75 | 42 |

| JPP180 | 180 | 460 | 30 | 25 | 21 | 60 | 31 |

| JPP200 | 200 | 508 | 30 | 20 | 16 | 65 | 34 |

Plastic Material Selection

When selecting the plastic, the application and the requirements for the plastic part are decisive. We process all common polymers from PA, PE, PP, ABS, PC, POM, PBT, PPA, PPS to PEEK.

Share Filters OEM Mesh Insert Plastic Moulded Filters

Why Work With Share Filters ?

Manufacturing - High quality materials, precise workmanship

In our factory we process all types of meshes for screens and filters in all sizes and designs. Our business activities span from cutting or punching to sewing, welding to mesh insert-moulding.

We manufacture according to customer drawing as well as to freehand sketch or model, considering the underlying standard tolerances and customized manufacturing standards. Experience and knowledge of our employees guarantee high-quality implementation.

Our customer base comes from a wide variety of industries including – Automotive, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory, Electronical as well as more general engineering, giving us a wealth of experience in many areas.

Share Filters Factory Capabilities

| Synthetic Mesh | Slitting | Cutting | Welding | Sewing | Injection Moulding |

|  |  |  |  |  |

| Share Filters synthetic meshes can be made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or cut shape. | Ultrasonic slitting is also used for manufacturing mesh strips and produces a closed edge with very little material build up at the edge. | Our cutting method include Laser cutting, cold cutting, heat cutting, slitting, stamping. professional cutting using custom made tools that will not damage the meshes. | Sonic welding are accurate, clean. Precision sleeves and bags for blood filtration, rosin bag for rosin press are examples of applications that benefit from this technology. | Share Filters sewing products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. | Custom plastic molded filters combine precise filter mesh with plastic. Industry serve: Automotive, Appliances, Food and beverage, Medical, Life Science and Laboratory. |

Photos of Share Filters Workshops

Contact us

Please connect with us so we can learn more about your application

and design specifications!