Share Group Limited |

|

Verified Suppliers

|

|

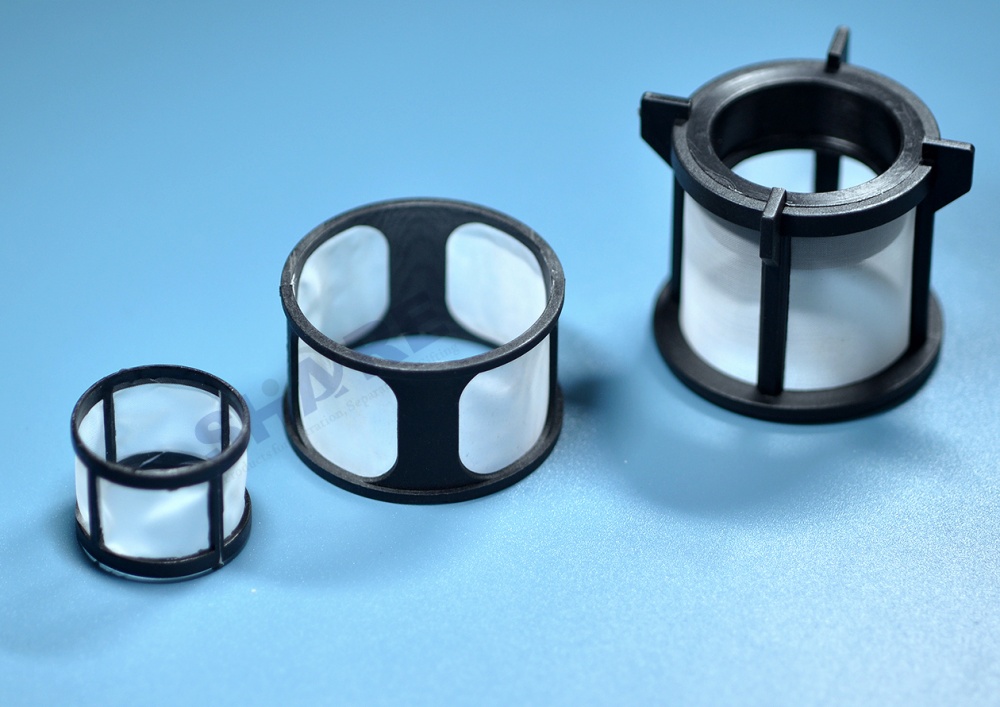

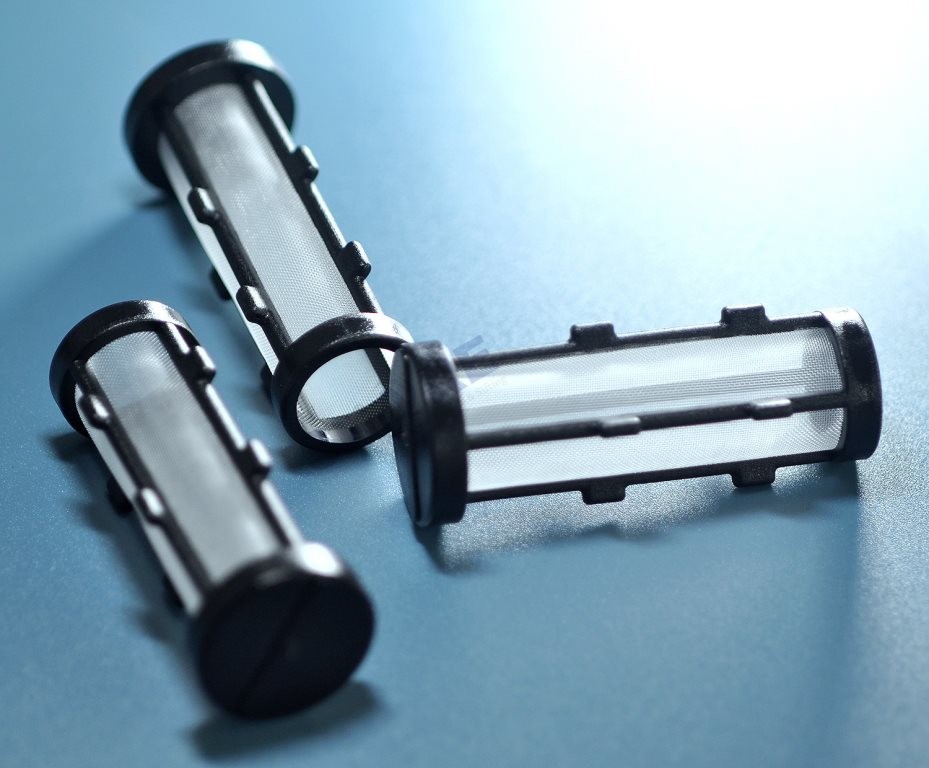

Toilet Flush Valve Piston Assembly Filter OEM Nylon Mesh Moulded Screen

The flush valve is responsible for controlling the release of water from the toilet tank into the bowl during flushing. The piston filter is a small screen or mesh located within the flush valve assembly. The purpose of the piston filter is to prevent debris, sediment, or other particles from entering the flush valve and potentially causing clogs or malfunctions.

Share Filters' piston filter combine the nylon or polyester filter mesh with plastic, allowing for a more robust part giving more reliability and longevity in its use. Injection moulding can take many forms and Share Filters is fully capable to help develop and produce the injection moulded filter products according your drawing that will best suit your needs, as well as, offering any additional advice or service along the way.

Share Filters Piston Filter Material Options

| Support rim material | PA, PET, PP, PC ABS, PE, POM, etc. |

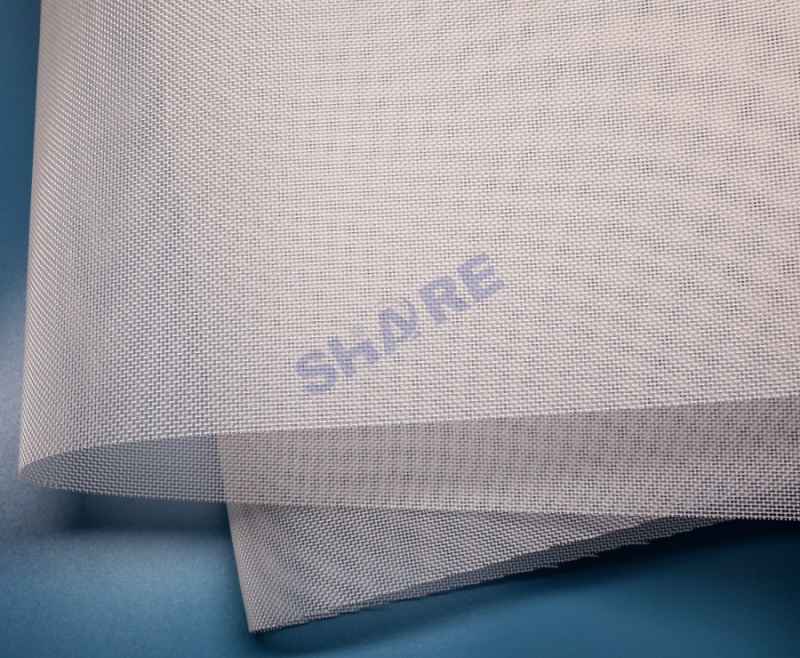

| Filter media | Nylon mesh, polyester mesh, PP mesh, metallic mesh | |

| Micron rating | 20μm - 500μm | |

| Mesh parts fabrication | Laser cutting, sonic cutting, sonic welding, heat welding |

| Process | Mesh insert injection moulding | |

| Specification | Custom | |

| Colour | Custom |

Nylon Filter Mesh Specification For Piston Filter

| Fabric number | Mest count | Thread diameter | Mesh opening | Open surface | Fabric thickness | Weight | |

| No. | mesh/cm | mesh/inch | micron | micron | % | micron | g/m2 |

| JPP12 | 12 | 30 | 250 | 583 | 49 | 470 | 162 |

| JPP12 | 12 | 30 | 300 | 533 | 41 | 585 | 234 |

| JPP14 | 14 | 35 | 300 | 414 | 34 | 595 | 273 |

| JPP16 | 16 | 40 | 200 | 425 | 46 | 370 | 139 |

| JPP16 | 16 | 40 | 250 | 375 | 36 | 485 | 217 |

| JPP20 | 20 | 50 | 150 | 350 | 49 | 375 | 98 |

| JPP20 | 20 | 50 | 200 | 300 | 36 | 385 | 173 |

| JPP24 | 24 | 60 | 150 | 267 | 41 | 285 | 117 |

| JPP28 | 28 | 70 | 120 | 237 | 44 | 215 | 87 |

| JPP30 | 30 | 76 | 120 | 213 | 41 | 225 | 94 |

| JPP32 | 32 | 80 | 100 | 213 | 46 | 165 | 69 |

| JPP36 | 36 | 90 | 100 | 178 | 41 | 178 | 78 |

| JPP40 | 40 | 100 | 100 | 150 | 36 | 190 | 87 |

| JPP43 | 43 | 110 | 80 | 152 | 43 | 135 | 60 |

Mesh Insert Injection Moulding

Share Filters' insert injection molding is the process of molding or forming thermoplastic parts around the filter media, especially the filter mesh. Moreover, insert molding combines the plastic support and filter mesh into a single unit. The process makes use of engineering plastics for improved wear resistance, tensile strength and weight reduction as well as using metallic materials for strength and conductivity.

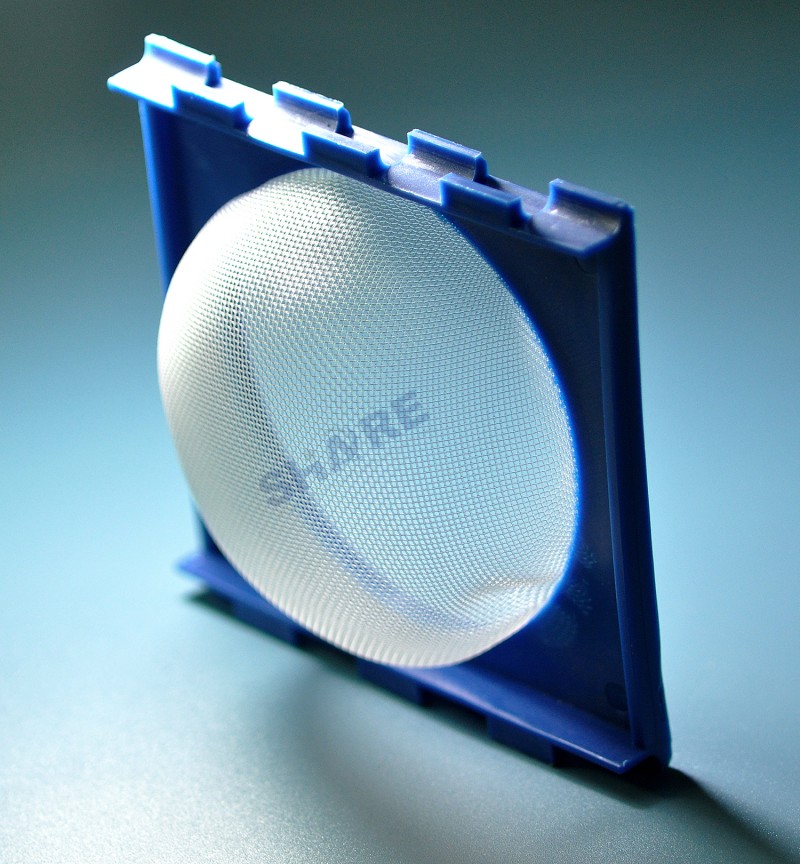

Share Filters Custom Plastic Moulded Filters Examples

Share Filters has a variety of manufacturing processes at our facility. Our current capabilities include filter mesh weaving, mesh slitting, laser die cutting, punching, sonic welding, heat welding, horizontal and vertical injection molding, etc.

Share Filters Factory Capabilities

| Synthetic Mesh | Slitting | Cutting | Welding | Sewing | Injection Moulding |

|  |  |  |  |  |

| Share Filters synthetic meshes can be made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or cut shape. | Ultrasonic slitting is also used for manufacturing fabric strips and produces a closed edge with very little material build up at the edge. | Our cutting method include Laser cutting, Cold cutting, Hot cutting, Slitting, Stamping. Professional cutting using custom made tools that will not damage the materials. | Sonic welding are accurate, clean. Precision sleeves and bags for blood filtration, rosin bag for rosin press are examples of applications that benefit from this technology. | Share Filters sewing products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. | Custom plastic molded filter combine precise filter mesh with polymer plastic. Industry serve: Automotive, Appliances, Food and beverage, Medical, Life Science and Laboratory. |

If you want a mesh insert manufacturing partner capable of providing you with the experience support system, look no further than Taizhou Share Filters Co., Ltd.