Share Group Limited |

|

Verified Suppliers

|

|

SHARE designs and manufactures standard snap-in cups that are suitable for the main intermediate proofer brands in the market, such as WP Haton, Beko, Kaak, Rondo, Rademaker, Sottoriva, Bongard, Benier, Mecatherm, Ferneto, Adamatic, AMF, Clock, KB, Kemper, Lawrence Equipment, Multifoods, Noel and Oshikiri.

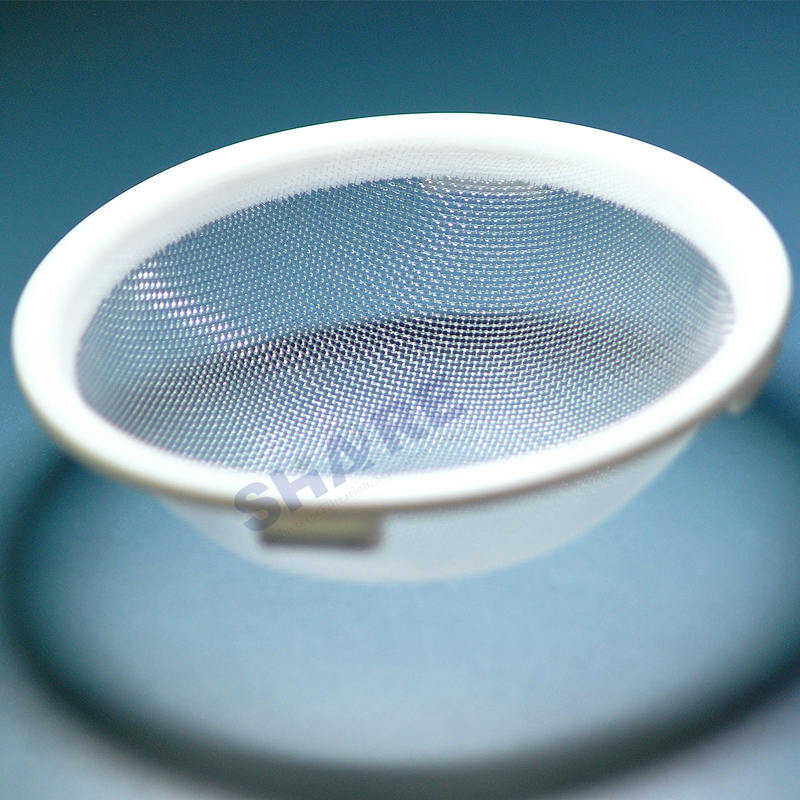

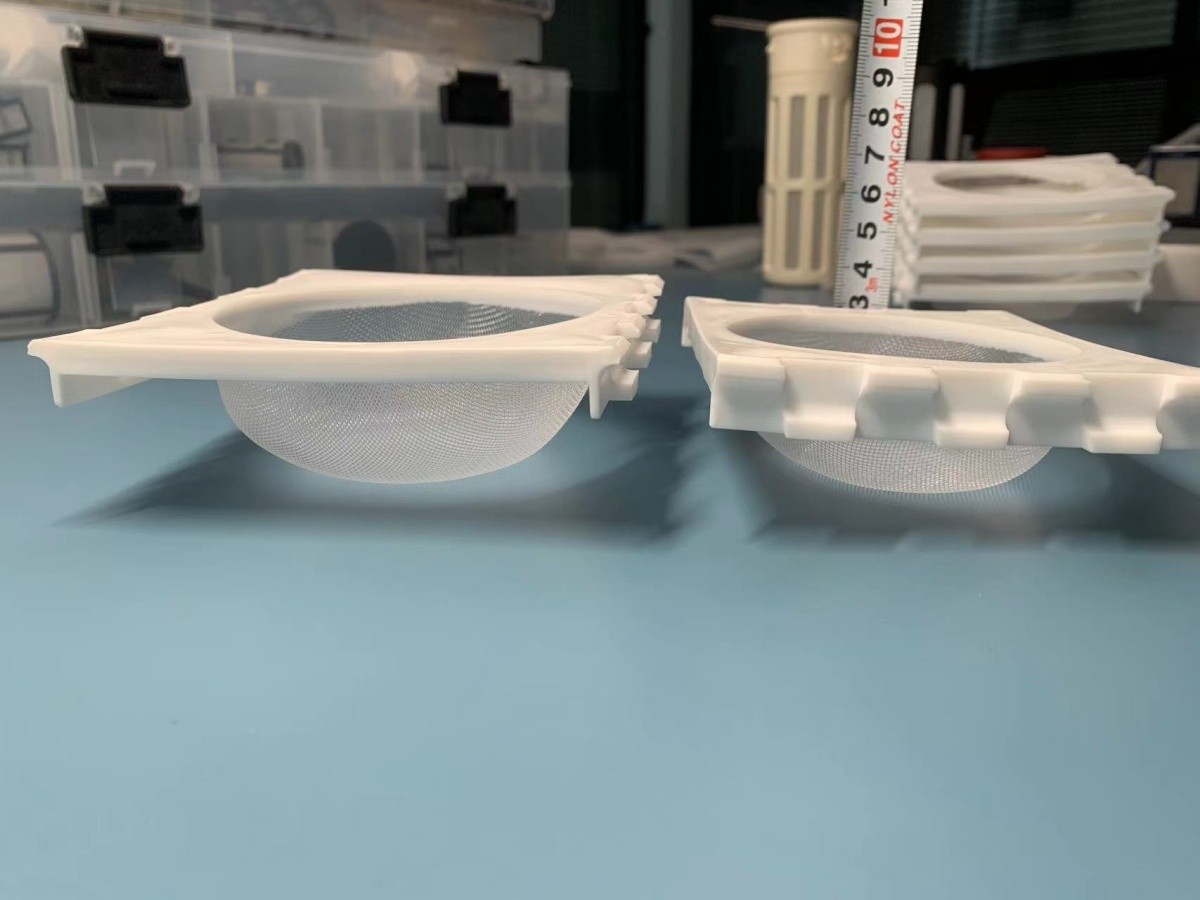

| Item | Round Cups for Intermediate Proofer |

| Type | SG-PC-07 | |

| Fits for | Intermediate proofer | |

| Rim Material | Polypropylene (PP) | |

| Mesh Material | Food grade nylon | |

| Outside Diameter | 198.7 mm | |

| Inner Diameter | 180.3 mm | |

| Mesh Depth | 100.5 mm | |

| Diameter hole in tray | 191 mm | |

| Package | 112pcs/41*42*51cm/6.1kg per carton | |

| Options |

|

DIMENSION IMAGE

| SHARE produces proofer cups and pockets in both round and square

shapes, made with food grade polypropylene resins and certified for

direct contact with food. Our meshes are available in many

different openings: T800, T420, T200 and code 95020, offered in

both nylon and polyester. Due to its chemical property, nylon and polyester mesh are safe and resistant to high temperature. Even under intensive use, continuous exposure to UV-C radiation, warm, humid climates, SHARE proofer cups maintain their durability & performance and feature excellent moisture, air and heat permeability. Custom proofer cups and pockets are also available. For non-standard machinery, SHARE can produce custom-specific cups as requeasted by plastic injection molding technology. All we need is a sample or a drawing with precise dimensions. |

RELATED PRODUCTS

PACKAGING & SHIPPING

For mesh rolls:

1. Rolled on the paper core, 30-70m/roll, packed into PE bags, the product label is attached on the edge of each roll

2. 2-8 rolls per standard export carton

3. Put into PP woven bag to prevent damage during transportation

4. Package belt strengthen

For fabricated filters:

1. Packed into sealed PE bags, 10pcs to 500pcs/bag according to the

actual size, double bagged and the product label is attached in the

inner bag

2. Put into bigger PE bag and then standard export carton

3. Wrapped the outer carton with PE stretch film to prevent damage

during transportation

4. Package belt strengthen if pallets are available

The label contains the following standard information:

item name, manufacturer, material, dimensions, manufacturing date,

order number, batch number etc.

| Port to Port | Door to Door | |

| Express(DHL,UPS,FEDEX, EMS) | 1 - 5 days | |

| Air Freight | 1 - 5 days | 4 - 10 days |

| Sea Freight(FCL) | 15 - 30 days | 20 - 35 days |

| Sea Freight(LCL) | 15 - 30 days | 22 - 37 days |

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are

one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your

evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly

notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically,

it takes 5 to 15 working days for us to complete mass production once you have

placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, our production operators

conduct self-inspections at every stage of the process.

Additionally, we have spot inspections and final inspections

carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting

capabilities from yarn over weaving to converted items with

professional technical team and quality guarantee and management

for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.