Share Group Limited |

|

Verified Suppliers

|

|

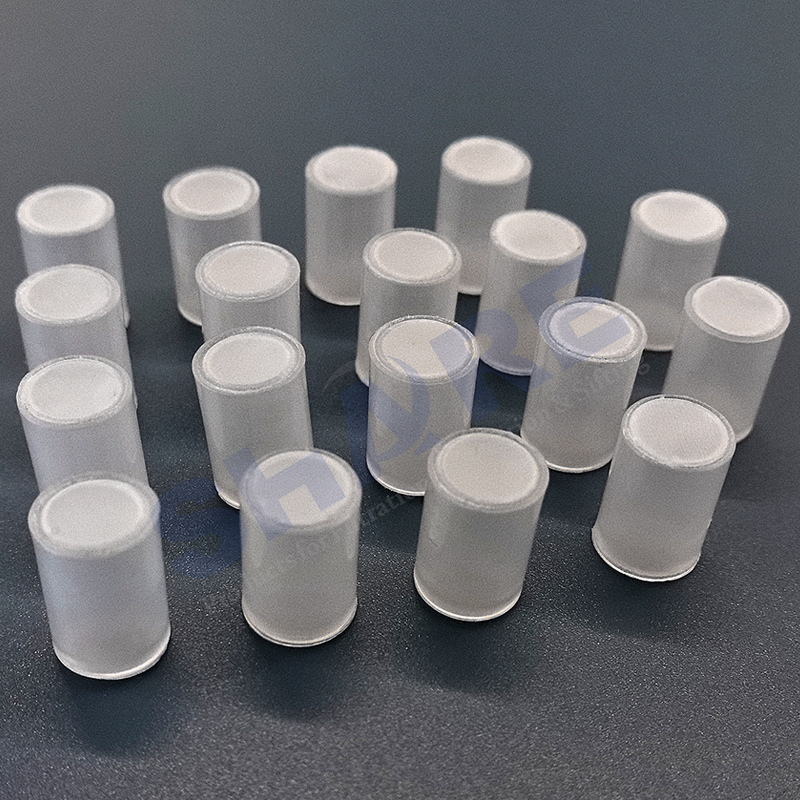

For a diverse range of applications—from cleaning agents to personal care products—the ability to evenly distribute or effectively foam liquids is essential. The SHARE foam generating tube is adept at accomplishing both. Our meticulously designed tubes are outfitted with two mesh surfaces for superior performance. Positioned on each side of the cylinder, these dual mesh screens introduce air into the liquid soap, resulting in a rich, foamy lather as the product is dispensed. In comparison to ordinary single-mesh designs, our dual-mesh approach significantly enhances the air-soap mixture, delivering a noticeably more abundant foam.

Dual Mesh Foam Tubes

Double fine mesh sieve guarantees perfect foam

| Product Name | Foam Generating Tube for Foaming Soap Dispensers |

| Manufacturer | Taizhou Share Filters Co. Ltd. |

| Brand | SHARE FILTERS |

| Material | PP frame, polyester or nylon or pp filter mesh |

| Color | White |

| Mesh weave type | Plain woven |

| Mesh opening | 75 µm 150 µm 180 µm mesh opening or custom micron ratings |

| Size | Customized |

| Processing technologies | Laser, ultrasonic, Insert molding |

| Certificate | ISO19001 ROHS REACH |

| Samples | Available |

| Custom Made | Available |

| Production lead time | 5 days to 15 days upon payment |

| Application | Used in foaming dispensers for soap, shampoo, or other liquid products that require a foamy output |

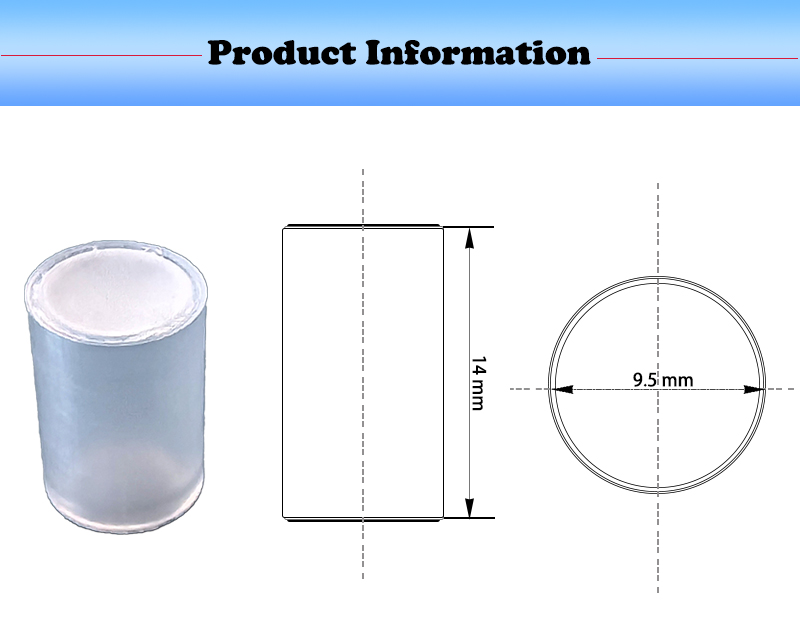

Dimensions

Gallery

Packaging & Shipping

For mesh rolls:

1. Rolled on the paper core, 30-70m/roll, packed into PE bags, the product label is attached on the edge of each roll

2. 2-8 rolls per standard export carton

3. Put into PP woven bag to prevent damage during transportation

4. Package belt strengthen

For fabricated filters & plastic filters:

1. Packed into sealed PE bags, 10pcs to 500pcs/bag according to the

actual size, double bagged and the product label is attached in the

inner bag

2. Put into bigger PE bag and then standard export carton

3. Wrapped the outer carton with PE stretch film to prevent damage

during transportation

4. Package belt strengthen if pallets are available

The label contains the following standard information:

item name, manufacturer, material, dimensions, manufacturing date,

order number, batch number etc.

| Port to Port | Door to Door | |

| Express(DHL,UPS,FEDEX, EMS) | 1 - 5 days | |

| Air Freight | 1 - 5 days | 4 - 10 days |

| Sea Freight(FCL) | 15 - 30 days | 20 - 35 days |

| Sea Freight(LCL) | 15 - 30 days | 22 - 37 days |

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are

one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your

evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly

notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically,

it takes 5 to 15 working days for us to complete mass production once you have

placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, our production operators

conduct self-inspections at every stage of the process.

Additionally, we have spot inspections and final inspections

carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting

capabilities from yarn over weaving to converted items with

professional technical team and quality guarantee and management

for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.