Share Group Limited |

|

Verified Suppliers

|

|

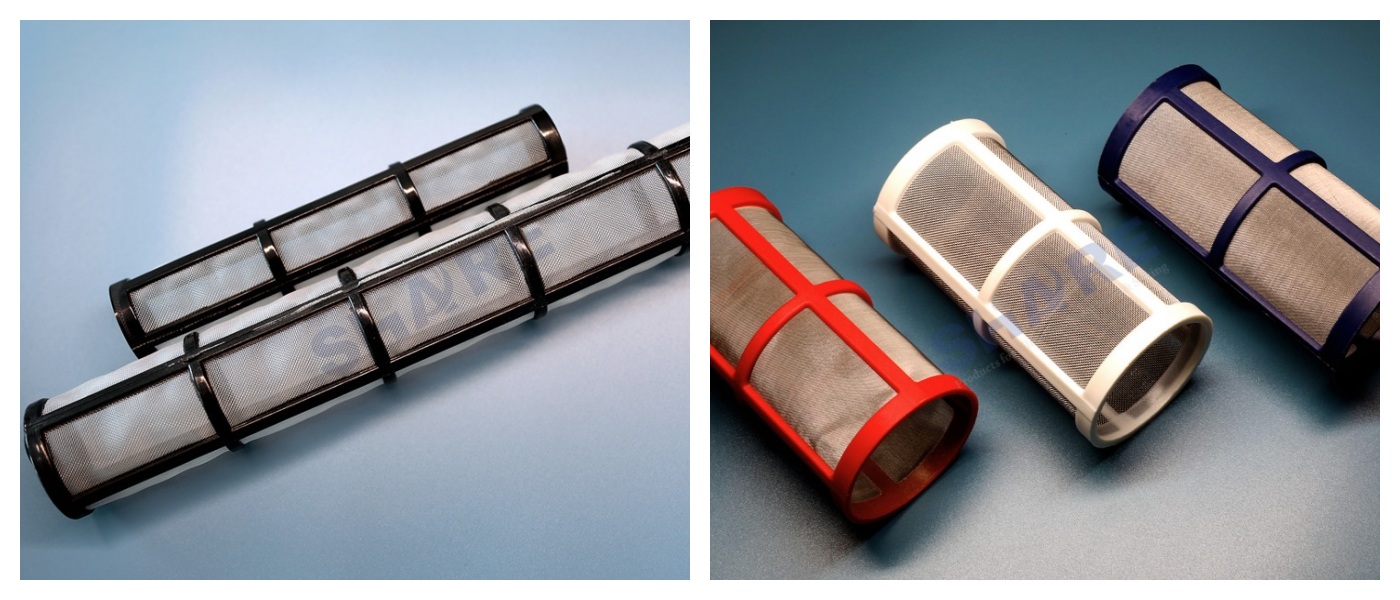

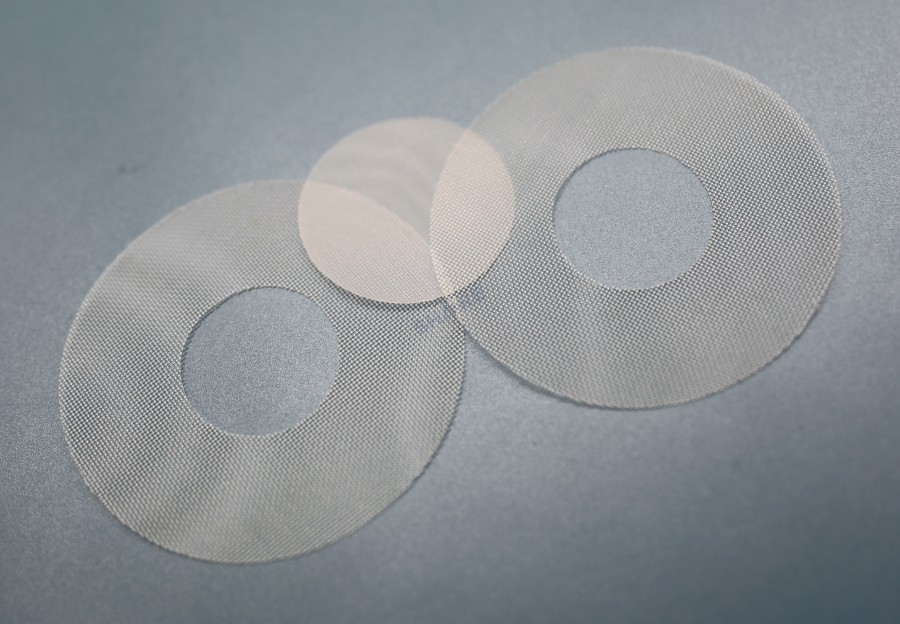

OEM Pressure Pot Filter 150 Micron Paint Spraying Cone-Shape Mesh Screen

A pressure pot filter, also known as a pressure feed tank filter, is a component used in paint spraying systems to ensure the purity and cleanliness of the paint or coating being applied. It helps prevent contaminants, such as dirt, debris, or particulate matter, from entering the spray gun and affecting the quality of the paint finish.

The pressure pot filter is typically assembled at the bottom of the pressure pot or tank, where the paint is stored under pressure. It acts as a barrier, allowing only clean paint to flow through to the spray gun while trapping any impurities present in the paint.

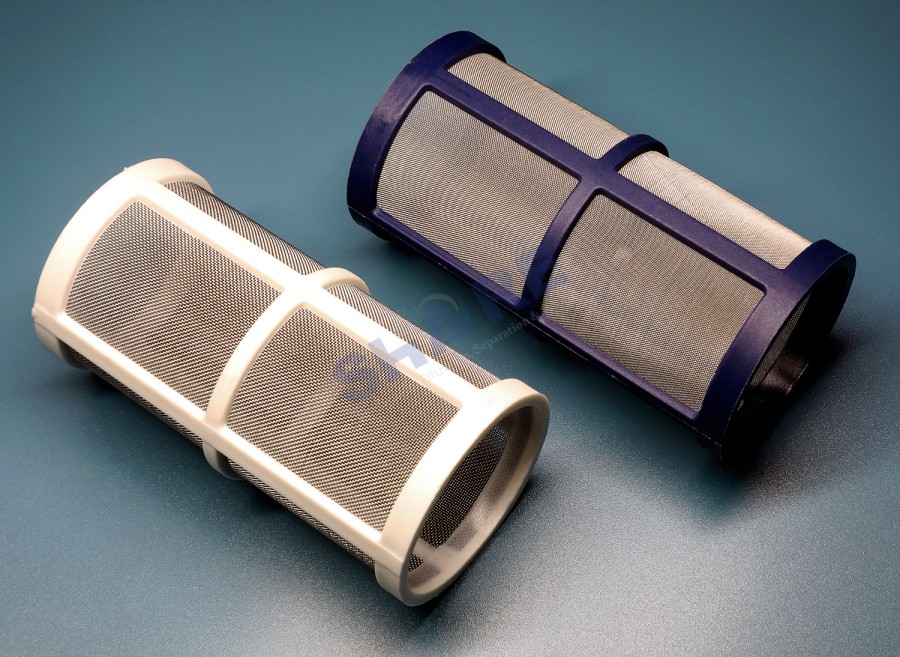

Share Filters' OEM pressure pot filters can come in various types and sizes, depending on the specific model and brand of the sprayer. They are often made of nylon mesh material or stainless steel combine with thermoplastic, which provides durability and effective filtration.

The Properties of Share Filters' OEM Paint Spraying Pressure Pot Filter :

The pressure pot filters play a crucial role in maintaining the quality of your paint finish, so it's important to choose the right filter media and perform regular maintenance to keep it in good working condition.

Share Filtes Pressure Pot Filter Materials Options

| Support Frame material | PA6, PA66, PET, PP, ABS, POM, etc. |

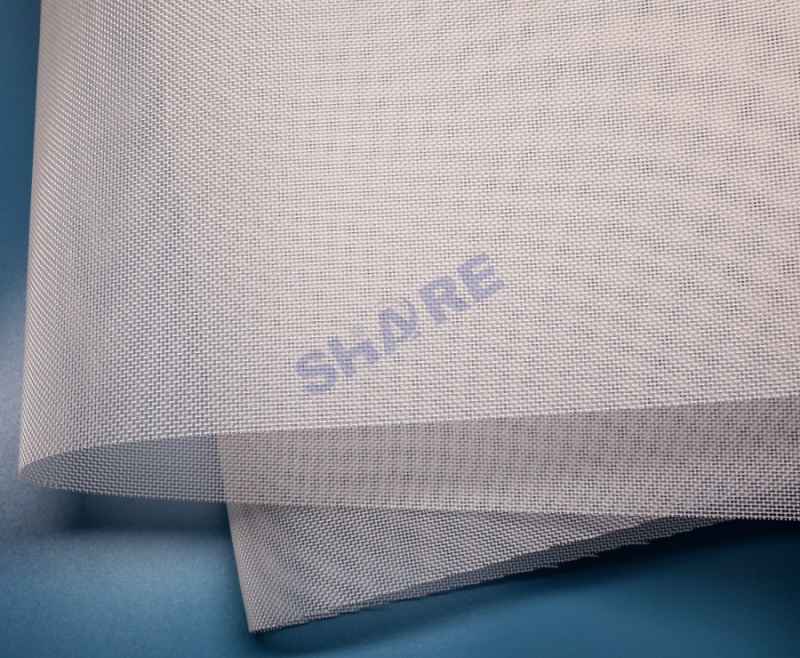

| Filter media | Nylon mesh, polyester mesh, stainless steel mesh | |

| Micron rating | 60μm - 300μm | |

| Mesh fabrication | Laser cutting, ultrasonic cutting, sonic welding |

| Processing | Mesh insert injection moulding, over moulding | |

| Specification | Custom | |

| Colour | Custom |

How To Select the Filter Mesh?

| You can follow these points.

|

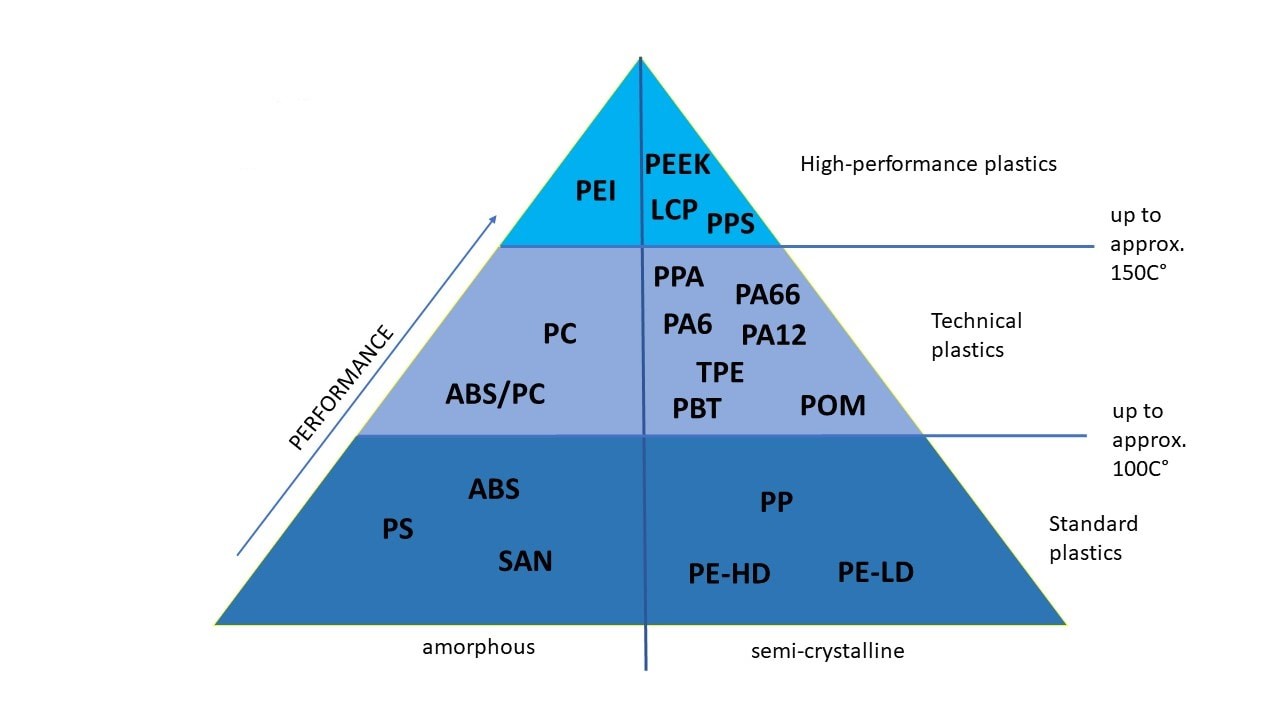

Properties of Polymer Plastic

PA6 (polyamide 6)

Tough, abrasion-resistant, good

vibration damping, resistant to solvents, fuels and lubricant

PA66 (polyamide6.6)

Rigid, stiff, abrasion-resistant, dimensionally stable

at heat exposure.

PET (polyethyleneterehthalate) High rigidity, high hardness, high

chemical resistance, good dimensional stability.

PP (polypropylene)

Good chemical resistance, more heat resistant

than PVC

PEEK (polyetheretherketone) High mechanical strength,

stiffness, toughness, temperature, chemical and radiation

resistance

How To Select The Right Filter Mesh? You Can Follow These Points.

PA(nylon) Filter Mesh Specification Paint Spraying Pressure Pot Filter

| Fabric number | Mest count | Thread diameter | Mesh opening | Open surface | Fabric thickness | Weight | ||

| No. | mesh/cm | mesh/inch | micron | micron | % | micron | g/m2 | |

| JPP14 | 14 | 35 | 300 | 414 | 34 | 595 | 273 | |

| JPP16 | 16 | 40 | 200 | 425 | 46 | 370 | 139 | |

| JPP16 | 16 | 40 | 250 | 375 | 36 | 485 | 217 | |

| JPP20 | 20 | 50 | 150 | 350 | 49 | 375 | 98 | |

| JPP20 | 20 | 50 | 200 | 300 | 36 | 385 | 173 | |

| JPP24 | 24 | 60 | 150 | 267 | 41 | 285 | 117 | |

| JPP28 | 28 | 70 | 120 | 237 | 44 | 215 | 87 | |

| JPP30 | 30 | 76 | 120 | 213 | 41 | 225 | 94 | |

| JPP32 | 32 | 80 | 100 | 213 | 46 | 165 | 69 | |

| JPP36 | 36 | 90 | 100 | 178 | 41 | 178 | 78 | |

| JPP40 | 40 | 100 | 100 | 150 | 36 | 190 | 87 | |

| JPP43 | 43 | 110 | 80 | 152 | 43 | 135 | 60 | |

| JPP48 | 48 | 120 | 80 | 130 | 38 | 145 | 62 | |

| JPP56 | 56 | 140 | 60 | 120 | 44 | 85 | 44 | |

| JPP59 | 59 | 150 | 60 | 110 | 42 | 98 | 46 | |

| JPP64 | 64 | 160 | 60 | 100 | 37 | 105 | 50 | |

| JPP72 | 72 | 180 | 50 | 90 | 41 | 82 | 39 | |

| JPP80 | 80 | 200 | 50 | 75 | 36 | 90 | 43 | |

| JPP100 | 100 | 250 | 42 | 60 | 36 | 65 | 35 | |

| JPP120 | 120 | 305 | 30 | 55 | 42 | 52 | 20 | |

| JPP120 | 120 | 305 | 35 | 45 | 29 | 60 | 28 | |

| JPP120 | 120 | 305 | 38 | 42 | 25 | 67 | 35 | |

| JPP120 | 120 | 305 | 42 | 42 | 25 | 75 | 42 | |

This data sheet just include our common specification, please contact us if you have other custom specification

Other Mesh Insert Injection Molded Filters

About Share Filters

Share has over 20 years of experience developing and manufacturing filter mesh and custom product solutions for our customer's screen and filtration needs. We can offer the filter mesh and filter components services including slitting, cutting, welding, sewing and injection molding. Our customer base comes from a wide variety of industries including – Automotive, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory, Electronical as well as more general engineering, giving us a wealth of experience in many areas.

Factory Capabilities

Filter mesh woven, Mesh Slitting, Cutting Shape, Welding, Sewing, Injection molding.

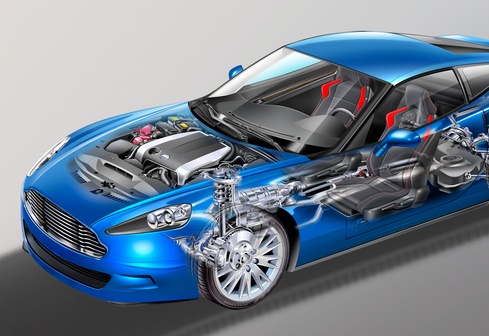

Share Filters Products Applications

|  |  |  |  | |

| Automotive | Appliance | Medical | Food & Beverage | Environmental |

Contact us

Please connect with us so we can learn more about your application

and design specifications!