Share Group Limited |

|

Verified Suppliers

|

|

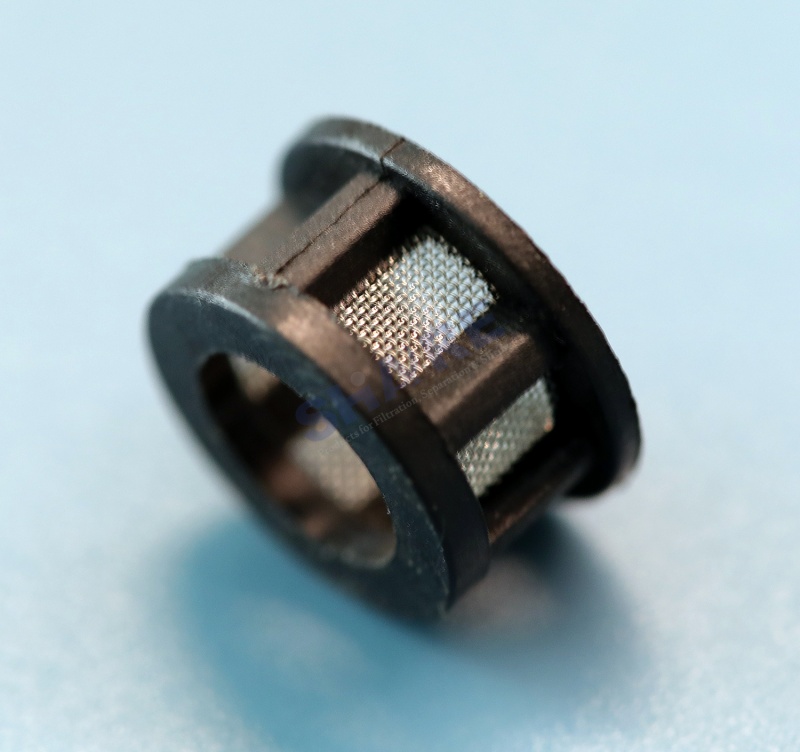

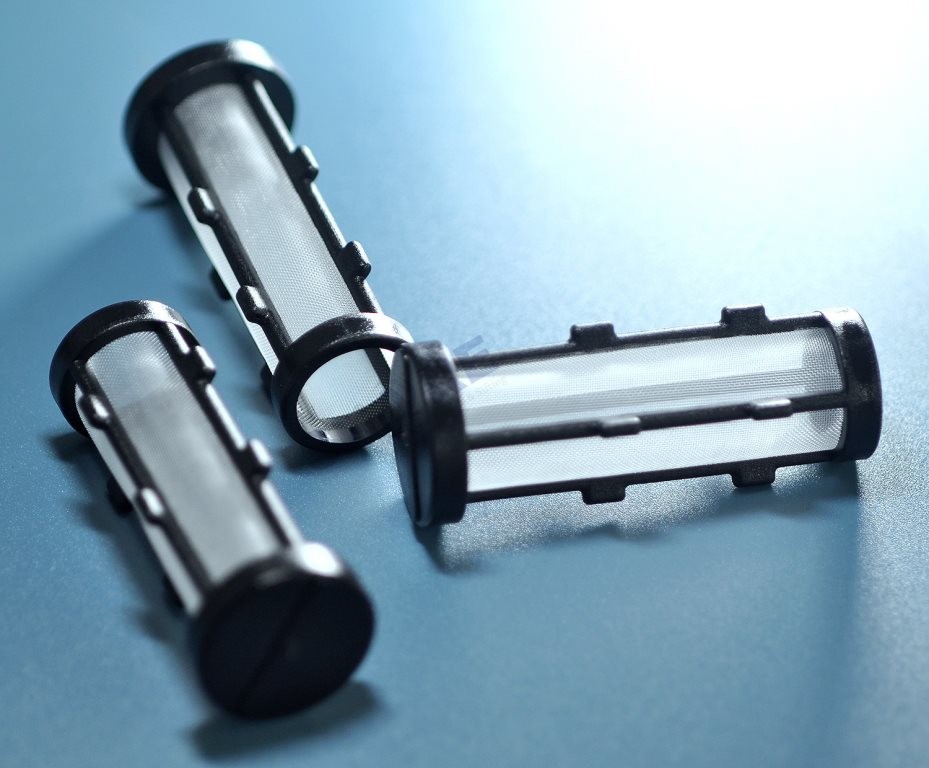

OEM Vehicle Oil Feeder Control Valve Filter With Stainless Steel Screen

The Vehicle oil control valve filter, also known as the OCV filter, is a small filter element that is often located within the oil control valve assembly. The purpose of this filter is to prevent any debris or contaminants from entering the oil control valve, which can affect its performance and potentially cause malfunctions.

The OCV filter is generally a small mesh or screen-like filter that is designed to capture any particles or debris that may be present in the oil. Over time, these filters can become clogged or restricted, hindering the proper flow of oil and potentially causing issues with the oil control valve's operation.

Share Filters' vehicle oil control valve filter combine the stainless steel screen with thermoplastic by the processing of mesh insert injection moulding, allowing for a more robust part giving more reliability and longevity in its use. Injection moulding can take many forms and Share Filters is fully capable to help develop and produce the injection moulded filter products that will best suit your needs, as well as, offering any additional advice or service along the way.

Solenoid valve filter

How To Choose Filter Mesh

Choose the mesh materials according to the environment such as the applicable temperature. The application cases mainly use metallic mesh, nylon mesh, polyester mesh. The mesh size can be adjusted according to the particle size of worried foreign objects, and the shape with the required strength can be proposed according to the layout of the installation position and the pressure of the path.

Share Filters' OEM Plastic Moulded Filters Materials Options

| Support rim material | PA6, PA66, PET, PP, ABS, brass, and other High- Performance Thermoplastics |

| Filter media | Stainless steel mesh, nylon mesh, polyester mesh, PP mesh, copper mesh |

| Micron rating | 60μm - 600μm |

| Mesh parts fabrication | Laser cutting, sonic cutting, sonic welding |

| Processing | Injection moulding |

| Specification | Custom |

Properties of Polymer Plastic

PA6 (polyamide 6)

Tough, abrasion-resistant, good

vibration damping, resistant to solvents, fuels and lubricant

PA66 (polyamide6.6)

Rigid, stiff, abrasion-resistant, dimensionally stable

at heat exposure.

PET (polyethyleneterehthalate) High rigidity, high hardness, high

chemical resistance, good dimensional stability.

PP (polypropylene)

Good chemical resistance, more heat resistant

than PVC

PEEK (polyetheretherketone) High mechanical strength,

stiffness, toughness, temperature, chemical and radiation

resistance

Share Filters Custom Filters Examples

Mesh Insert Injection Molding Production

Share Filters' insert injection molding is the process of molding or forming thermoplastic parts around the filter media, especially the filter mesh. Moreover, insert molding combines the plastic support and filter mesh into a single unit. The process makes use of engineering plastics for improved wear resistance, tensile strength and weight reduction as well as using metallic materials for strength and conductivity.

Nylon Filter Mesh Specification For Vehicle Oil Control Valve Filter

| Ref. No. | Mesh Count | Thread Diam. | Mesh Opening | Opening Area | |

| mesh/cm | mesh/inch | µm | µm | % | |

| JPP10 | 10 | 25 | 300 | 700 | 49 |

| JPP12 | 12 | 30 | 250 | 583 | 49 |

| JPP12 | 12 | 30 | 300 | 533 | 41 |

| JPP14 | 14 | 35 | 300 | 414 | 34 |

| JPP16 | 16 | 40 | 200 | 425 | 46 |

| JPP16 | 16 | 40 | 250 | 375 | 36 |

| JPP20 | 20 | 50 | 150 | 350 | 49 |

| JPP20 | 20 | 50 | 200 | 300 | 36 |

| JPP24 | 24 | 60 | 150 | 267 | 41 |

| JPP28 | 28 | 70 | 120 | 237 | 44 |

| JPP30 | 30 | 76 | 120 | 213 | 41 |

| JPP32 | 32 | 80 | 100 | 213 | 46 |

| JPP36 | 36 | 90 | 100 | 178 | 41 |

| JPP40 | 40 | 100 | 100 | 150 | 36 |

| JPP43 | 43 | 110 | 80 | 152 | 43 |

| JPP48 | 48 | 120 | 80 | 130 | 38 |

| JPP56 | 56 | 140 | 60 | 120 | 44 |

| JPP59 | 59 | 150 | 60 | 110 | 42 |

| JPP64 | 64 | 160 | 60 | 100 | 37 |

| JPP72 | 72 | 180 | 50 | 90 | 41 |

| JPP80 | 80 | 200 | 50 | 75 | 36 |

| JPP100 | 100 | 250 | 40 | 60 | 36 |

Please connect with us so we can learn more about your application and design specifications!