Custom Fod Filter With Stainless Steel Screen

For Aircraft Turbine Jet Engines

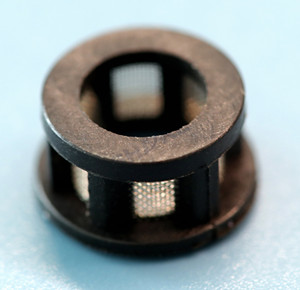

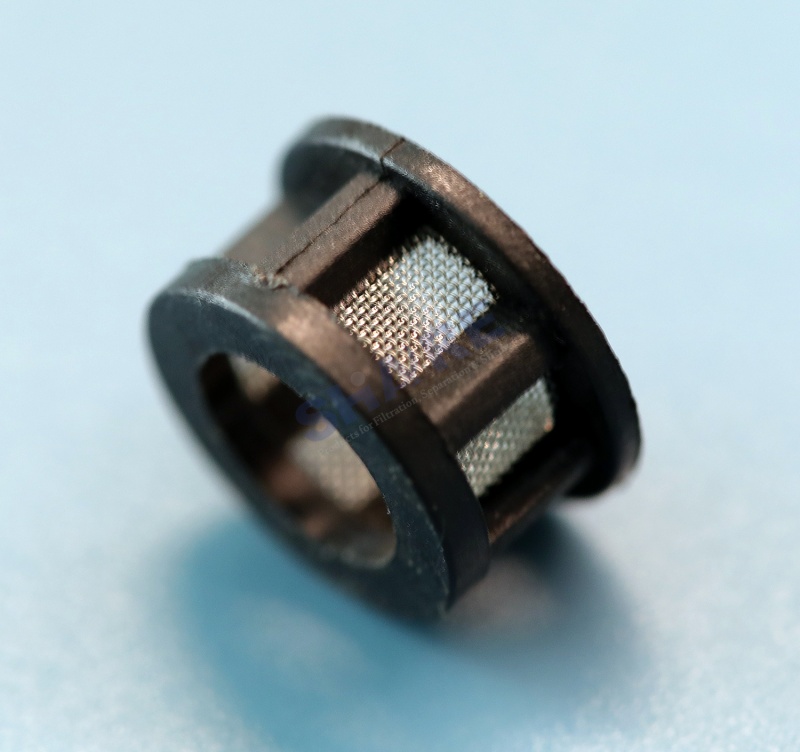

A FOD (Foreign Object Damage) filter is exclusively designed and manufactured for Jets Munt Turbines,

it's an essential component for protecting jet engines, including

those manufactured by Jets Munt. FOD filters are designed to

prevent foreign objects, such as debris, dust, or small particles,

from entering the engine during operation. These filters help

maintain the performance, reliability, and longevity of the

turbine.

Share Filters' FOD filter meets relevant industry standards and

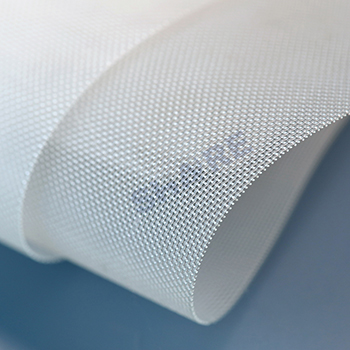

regulations for aviation safety. It consists of a stainless steel mesh held in a polymer plastic

frame, allowing for a more robust part/product giving more

reliability and longevity in its use. This filter is durable and

replaceable. This type of filter tends to be the larger practical.

It is very easy to installation.

Upside diam: custom size

Down side diam: custom size

Height: custom size

FOD screen material: stainless

steel or galvanized

FOD screen micron: by specify

Application: protects jet engine absorbing larger objects

Share Filters Plastic Molded Filters Options

| Support frame material | PA6, PA66, PET, PP, ABS, and other thermoplastics |

| Filter media | Metallic mesh, Nylon mesh, polyester mesh, PP mesh, |

| Micron rating | 3μm - 3000μm |

| Mesh parts fabrication | Laser cutting, punching |

| Processing | Insert injection molded filter, over moulding |

| Specification | Custom |

| Color | Custom |

How to Select the Right Filter Mesh?

You can follow these points.

- Opening size or the size of the particle you need to filter

- Mesh material (consider the working condition)

- Mesh thread diameter, mesh thickness

- Opening area

Stainless Filter Mesh Specification

| Mesh count (per inch) | Thread diameter (microns) | Aperture | Open Area (%) | Weight (IB) /100 square foot |

| | Inch | mm | Inch | mm | | |

| 1x1 | 0.080 | 2.03 | 0.920 | 23.37 | 84.6 | 41.1 |

| 2x2 | 0.063 | 1.60 | 0.437 | 11.10 | 76.4 | 51.2 |

| 3x3 | 0.054 | 1.37 | 0.279 | 7.09 | 70.1 | 56.7 |

| 4x4 | 0.063 | 1.60 | 0.187 | 4.75 | 56.0 | 104.8 |

| 4x4 | 0.047 | 1.19 | 0.203 | 5.16 | 65.9 | 57.6 |

| 5x5 | 0.041 | 1.04 | 0.159 | 4.04 | 63.2 | 54.9 |

| 6x6 | 0.035 | 0.89 | 0.132 | 3.35 | 62.7 | 48.1 |

| 8x8 | 0.028 | 0.71 | 0.097 | 2.46 | 60.2 | 41.1 |

| 10x10 | 0.025 | 0.64 | 0.075 | 1.91 | 56.3 | 41.2 |

| 10x10 | 0.020 | 0.51 | 0.080 | 2.03 | 64.0 | 26.1 |

| 12x12 | 0.023 | 0.584 | 0.060 | 1.52 | 51.8 | 42.2 |

| 12x12 | 0.020 | 0.508 | 0.063 | 1.60 | 57.2 | 31.6 |

| 14x14 | 0.023 | 0.584 | 0.048 | 1.22 | 45.2 | 49.8 |

| 14x14 | 0.020 | 0.508 | 0.051 | 1.30 | 51.0 | 37.2 |

| 16x16 | 0.018 | 0.508 | 0.0445 | 1.13 | 50.7 | 34.5 |

| 18x18 | 0.017 | 0.432 | 0.0386 | 0.98 | 48.3 | 34.8 |

| 20x20 | 0.020 | 0.508 | 0.0300 | 0.76 | 36.0 | 55.2 |

| 20x20 | 0.016 | 0.406 | 0.0340 | 0.86 | 46.2 | 34.4 |

| 24x24 | 0.014 | 0.356 | 0.0277 | 0.70 | 44.2 | 31.8 |

| 30x30 | 0.013 | 0.330 | 0.0203 | 0.52 | 37.1 | 34.8 |

| 30x30 | 0.012 | 0.305 | 0.0213 | 0.54 | 40.8 | 29.4 |

| 30x30 | 0.009 | 0.229 | 0.0243 | 0.62 | 53.1 | 16.1 |

| 35x35 | 0.011 | 0.279 | 0.0176 | 0.45 | 37.9 | 29.0 |

| 40x40 | 0.010 | 0.254 | 0.0150 | 0.38 | 36.0 | 27.6 |

| 50x50 | 0.009 | 0.229 | 0.0110 | 0.28 | 30.3 | 28.4 |

| 50x50 | 0.008 | 0.203 | 0.0120 | 0.31 | 36.0 | 22.1 |

| 60x60 | 0.0075 | 0.191 | 0.0092 | 0.23 | 30.5 | 23.7 |

Share Filters, an OEM Mesh Insert Molded Filters Manufacture From China

As an filter meshes and filter components manufacture , Share

Filters always find the best solution is to work with our OEM

customers to collaborate on their mesh filtration product

development projects before the final design prints are completed.

Our experienced engineers are able to not only to meet your

functional requirements, but also to recommend design alterations

to improve performance and manufacturability. We will

concentrate on the following:

| Consider Area | | Factors | Outcoming |

Filtration

Media

|  | Select right material, weave, pore, thread diam, heat treatment,

coatings | Media selected meets the required performance |

Component Design

|  | Consider supporting media, housing, end caps | Ther filtration components can perform well in working condition |

Manufacturing Process

|  | Design lends itself to easy manufacture and economic cost? | Produced at low cost of manufacture and hign efficiency |

Quality Control

|  | Determine parameters and frequency of measurement | High quality, precision filter components |

Manufacturing - High Quality Materials, Precise Workmanship

In our factory we process woven filter mesh for screens and filters

in all sizes and designs. Our business activities span from cutting

or punching to sewing, gluing and welding to insert-molding of the

different fabrics.

We manufacture according to customer drawing as well as to freehand

sketch or model, considering the underlying standard tolerances and

customized manufacturing standards. Experience and knowledge of our

employees guarantee high-quality implementation.

Custom Plastic Molded Filters

As a primary mesh supplier serving filtration OEM filters, you can

benefit from Share's experience helping our customers develop

thousands of products by engaging with our filtration solutions

team. Contact us now if you have filtration inquiry.