Share Group Limited |

|

Verified Suppliers

|

|

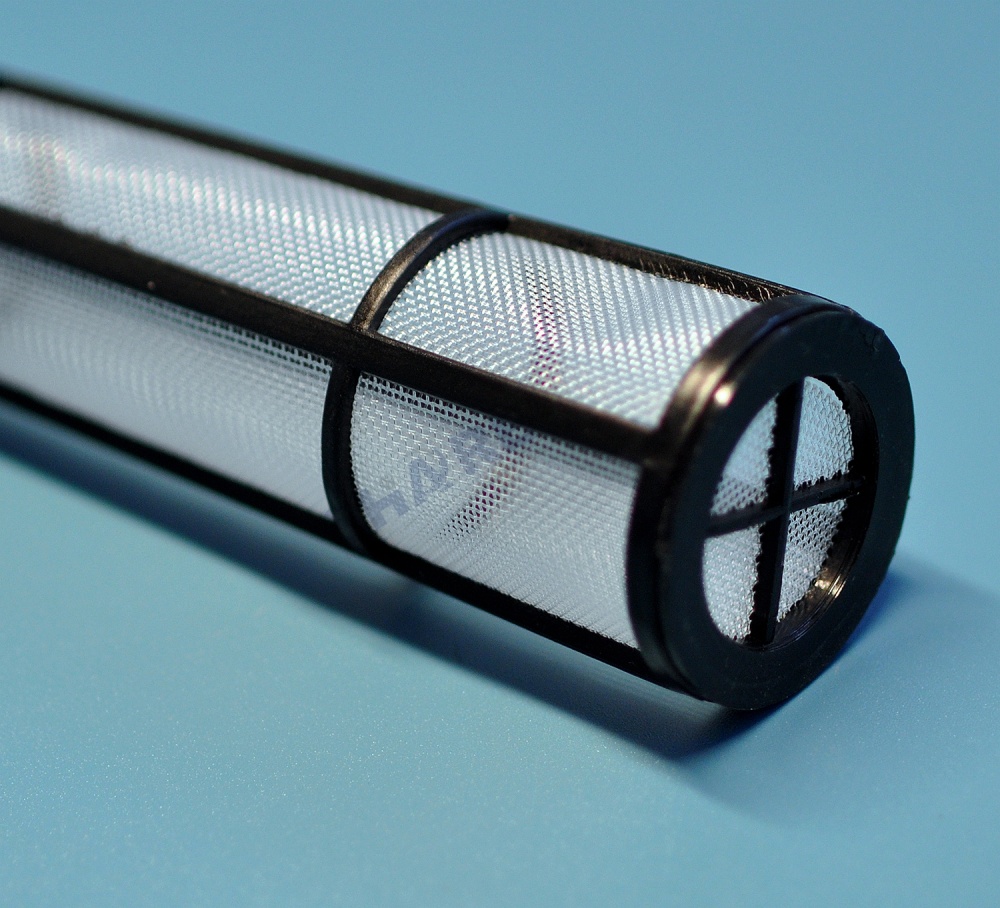

Coffee Maker Component Filter Plate Disc Filter With Mesh Screen

The process of manufacturing a disc filter is by moulding a plastic or rubber material onto a filter media. This process involves placing a filter media, usually we ues nylon filter mesh, polyester filter mesh, PP filter mesh and metalic filter mesh, into a mold and injecting a molten plastic or rubber material around it. The plastic or rubber material then hardens, creating a seal around the filter media and forming a disc-shaped filter.

Share Filters' disc filters can be customized to fit specific applications by varying the filter media, support cage material type, and size.

Coffee Maker Disc Filters Materials Options

| Support rim frame material: | PA6, PA66, PET, PP, ABS, and other High-Performance Thermoplastics |

| Filter media: | Nylon mesh, polyester mesh, PP mesh, metallic mesh |

| Micron rating: | 20μm - 800μm |

| Mesh parts fabrication: | Laser cutting, Punching |

| Plastic Process: | Over moulding, insert injection moulding |

| Specification: | Custom |

| Colour: | Custom |

This disc filter is welded to the tubular filter as the cover

Disc filters are commonly used in a variety of applications, including automotive, and medical, home appliances and industry. They are often used in filtration systems to remove particulates and contaminants from liquids or gases, and some used as the air vents.

Other Disc Shaped Filters Serve for Different Industies

How To Choose the Right Material and Make the Filters?

We Should Take Below Factors into Consideration:

Properties of Thermoplastic

| Material | PA6 | PA66 | PET | PP | PEEK |

| Specific gravity (g/mm²) | 1.14 | 1.14 | 1.38 | 0.91 | 1.30 |

| Tensile strength(daN/mm²) | 41-67 | 41-67 | 45-75 | 35-62 | 33-75 |

| Relative strength at wet conditions(%) | 89-90 | 85-90 | 100 | 100 | 100 |

| Elongation at break (%) | 20-35 | 20-35 | 15-30 | 20-50 | 20-40 |

| Moisture absorption at 20°C / 65% r.h. (%) | 3.5-4 | 3.5-4 | 0.4 | 0 | 0.1 |

| Melting point (°C) | 210-220 | 260-268 | 250-260 | 165-175 | 334 |

| Softening point (°C) | - | - | 220-240 | 140-155 | 300 |

| Working temperature dry (°C) | - | - | -75 to +150 | -30 to +90 | up to 250 |

| Stability to light | poor | poor | poor | poor | good |

| Atmospheric influence | - | - | none | none | none |

| Abrasion resistance | good | good | limited | limited | good |

| Acid resistance | limited-poor | limited-poor | good | good | good |

| Alkaline resistance | good | good | limited | good | good |

| Stability to solvents | limited | limited | good | good | good |

| Hydrolysis resistance | good | good | limited | good | good |

About Share Filters

Share has over 20 years of experience developing and manufacturing filter mesh and custom product solutions for our customer's screen and filtration needs. We can offer the one-stop filtration solution services from filter media to filter mesh slitting, cutting, welding, sewing and mesh insert injection molding. We insert and over moldsynthetic mesh, stainless steel wires as well as other metalic mesh for molded filter components. Our customer base comes from a wide variety of industries including – Automotive, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory, Electronical as well as more general engineering, giving us a wealth of experience in many areas.

|  |  |  |  |  |

| Automotive | Appliance | Medical | Food & Beverage | Chemical | Environmental |

Factory Capacities

|  |  |  |  |  |

| Share Filters synthetic meshes can be made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or cut shape. | Ultrasonic slitting is also used for manufacturing fabric strips and produces a closed edge with very little material build up at the edge. | Our cutting method include Laser cutting, Cold cutting, Hot cutting, Slitting, Stamping. Professional cutting using custom made tools that will not damage the materials. | Sonic welding are accurate, clean. Precision sleeves and bags for blood filtration, rosin bag for rosin press are examples of applications that benefit from this technology. | Share Filters sewing products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. | Custom plastic molded filter combine precise filter mesh with polymer plastic. Industry serve: Automotive, Appliances, Food and beverage, Medical, Life Science and Laboratory. |

Do You Have Filtration Inquiry ? Contact Us