Share Group Limited |

|

Verified Suppliers

|

|

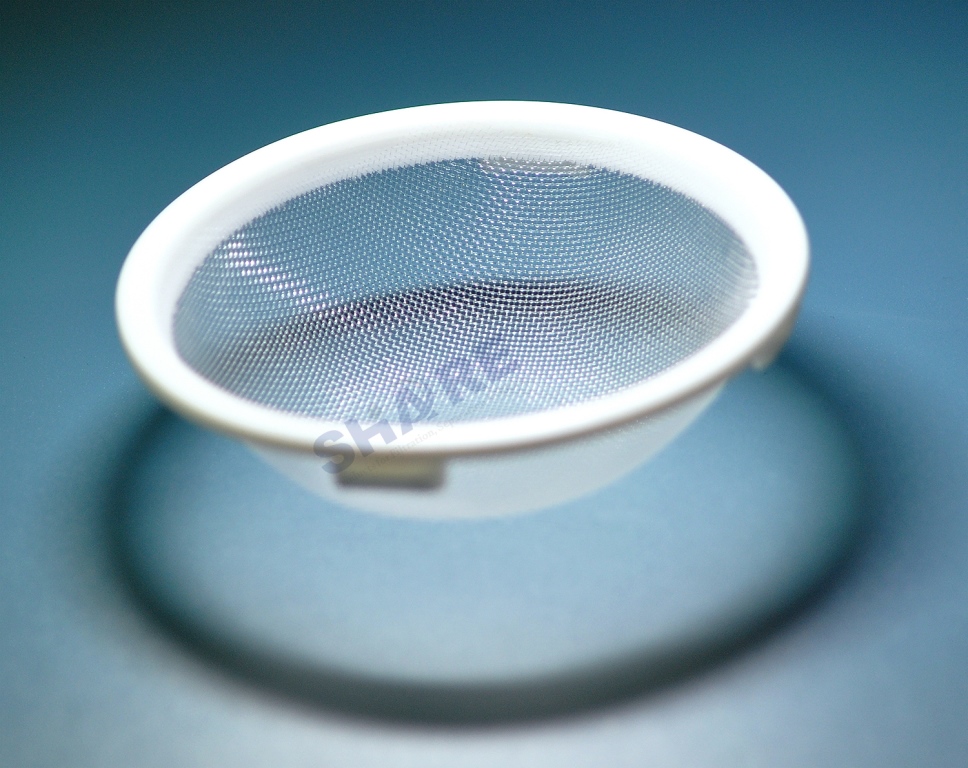

Round Bread Roll Line Cup Nylon Mesh For Proofer Machine Or Resting Cabinet

Share Filters bread roll proofer cup is designed for a long lifespan, even with intensive use and a warm and humid climate. It's designed with snap-in retainer tabs that will not break off. These proofers allow the dough to develop, resulting in a better final product.

The open mesh provides excellent air permeability around the dough, and the pockets’ design enhanced and superb cleaning results. Share Filters' fine mesh and coarse proofer cups are ideal for commercial bakeries around the world.

Custom ound Proofer Cup

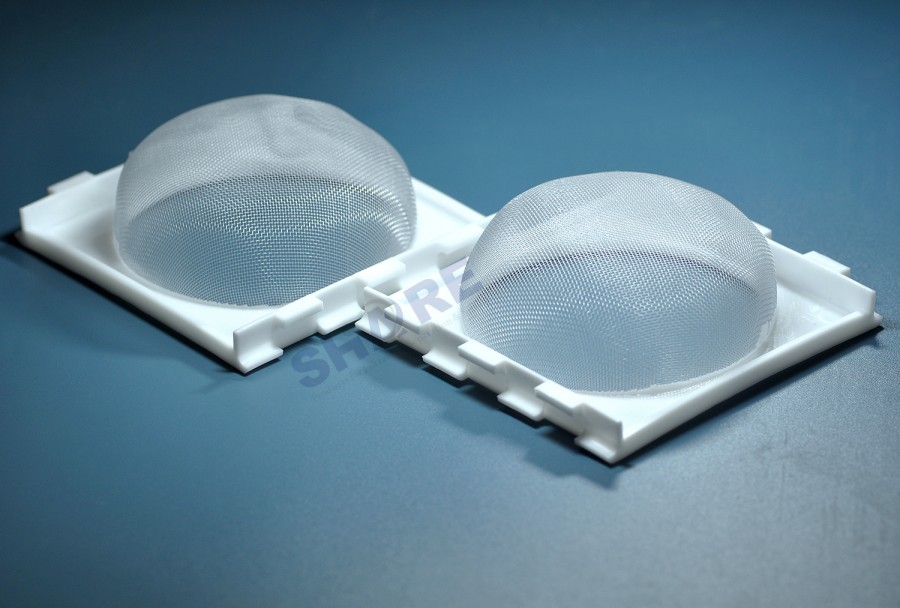

Square proofer cup

Advantage of Share Filter Bread Roll Proofer Cup

Custom Cup Is Available

For non-standard machinery, Share Filter is equipped to manufacture tailormade baskets and proofing meshes. All we require is a good sample or diagram with accurate dimensions.

Nylon Filter Mesh Data Sheet

| Ref. No. | Mesh Count | Thread Diam. | Mesh Opening | Opening Area | |

| mesh/cm | mesh/inch | µm | µm | % | |

| JPP9 | 9 | 24 | 250 | 860 | 60 |

| JPP10 | 10 | 25 | 300 | 700 | 49 |

| JPP12 | 12 | 30 | 250 | 583 | 49 |

| JPP12 | 12 | 30 | 300 | 533 | 41 |

| JPP14 | 14 | 35 | 300 | 414 | 34 |

| JPP16 | 16 | 40 | 200 | 425 | 46 |

| JPP16 | 16 | 40 | 250 | 375 | 36 |

| JPP20 | 20 | 50 | 150 | 350 | 49 |

| JPP20 | 20 | 50 | 200 | 300 | 36 |

| JPP24 | 24 | 60 | 150 | 267 | 41 |

| JPP28 | 28 | 70 | 120 | 237 | 44 |

| JPP30 | 30 | 76 | 120 | 213 | 41 |

| JPP32 | 32 | 80 | 100 | 213 | 46 |

| JPP36 | 36 | 90 | 100 | 178 | 41 |

| JPP40 | 40 | 100 | 100 | 150 | 36 |

Factory Facilities

Share Filters manufacturing facilities can provide tailor-made solutions for a wide range of production processes as well as custom made designs that are guaranteed to produce the best quality final product.

Share Filters has over 20 years of experience developing and manufacturing filter mesh and custom product solutions for our customer's screen and filtration needs. We employ experienced staffs of engineers and toolmakers to assist in the design of, and frequently build the tooling necessary to manufacture custom products combining synthetic mesh or metallic mesh with thermo-plastic. We have a variety of manufacturing processes at our facility. Our current production lines include filter mesh weaving, mesh slitting, laser die cutting, sonic welding, horizontal and vertical injection molding, stamping, etc.

|  |  |  |  |  |

| Share Filter synthetic meshes can be made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or cut shape. | Ultrasonic slitting is also used for manufacturing fabric strips and produces a closed edge with very little material build up at the edge. | Our cutting method include Laser cutting, Cold cutting, Hot cutting, Slitting, Stamping. Professional cutting using custom made tools that will not damage the materials. | Sonic welding are accurate, clean. Precision sleeves and bags for blood filtration, rosin bag for rosin press are examples of applications that benefit from this technology. | Share Filters sewing products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. | Custom plastic molded filter combine precise filter mesh with polymer plastic. Industry serve: Automotive, Appliances, Food and beverage, Medical, Life Science and Laboratory. |

Please connect with us so we can learn more about your application and design specifications!