BOGEN PUMPS |

|

Verified Suppliers

|

|

Industrial Acid Diaphragm Pump / Self Priming Low Pressure Diaphragm Pump

Acid Diaphragm Pump Introdution

(also know as a Membrane pump, air operated double diaphragm pump(AOOD)or pneumatic diaphragm pump)that uses a combination of the reciprocating action of a rubber,thermoplastic or diaphragm and suitable valves either side of the diaphragm (check valve,butterfly valves,flap valves,or any other form of shut-off valves) to pump a fluid.

| Item | Description | Unit | Reference Figure |

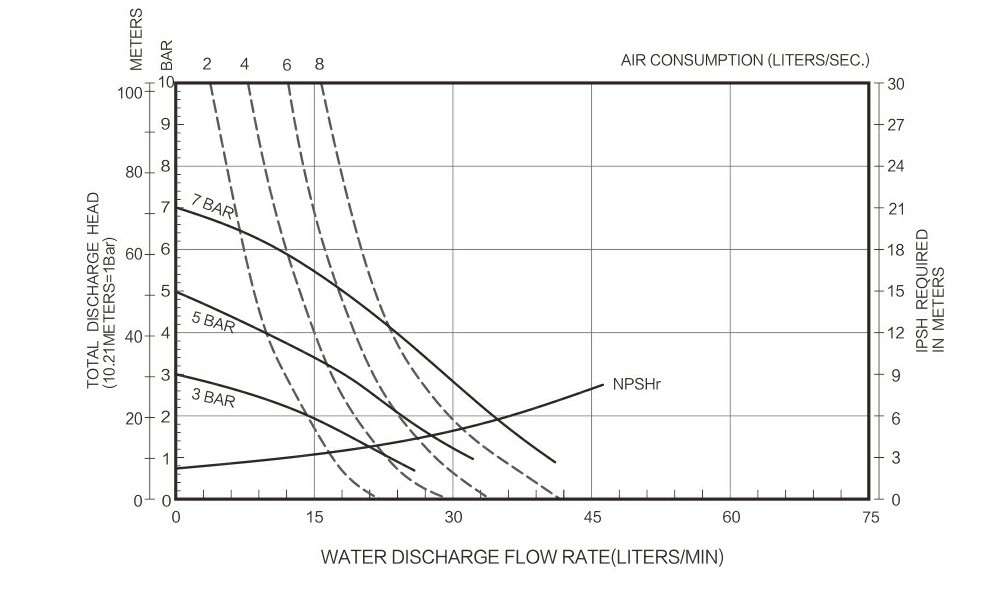

| 1 | Maximum air inlet pressure | Mpa | 0.6 |

| 2 | Maximum flow rate | 1/Min | 27 |

| 3 | Maximum lift | M | 45 |

| 4 | Maximum outlet pressure | Mpa | 0.6 |

| 5 | Maximum particle size | mm | 1 |

| 6 | Weight | kg | 1.8 |

| 7 | Noise level | db | <68 |

| 8 | Max dry suction | m | 4.2 |

Main Advantages

1, Due to the use of air power, the flow automatically changed

according to export resistance. Which is suitable for high

viscosity fluid.

2, In inflammable and explosive environment, the pump is reliable

and low cost, won't produce spark and not overheat,

3, The pump volume is small, easy to move, no foundation needed,

convenient installation and economy. Can be used as mobile

conveying pump.

4, Where there are dangers, corrosive materials processing,

diaphragm pump can be separated completely with outside.

5, The pump shearing force is low, physical effect to medium is

small, can be used for conveying unstable chemistry fluid.

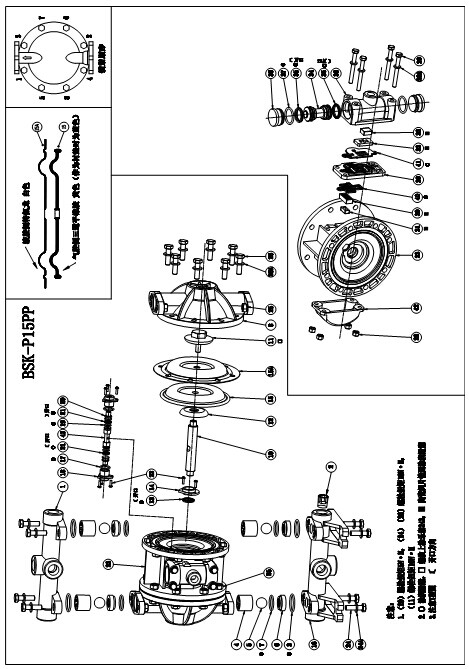

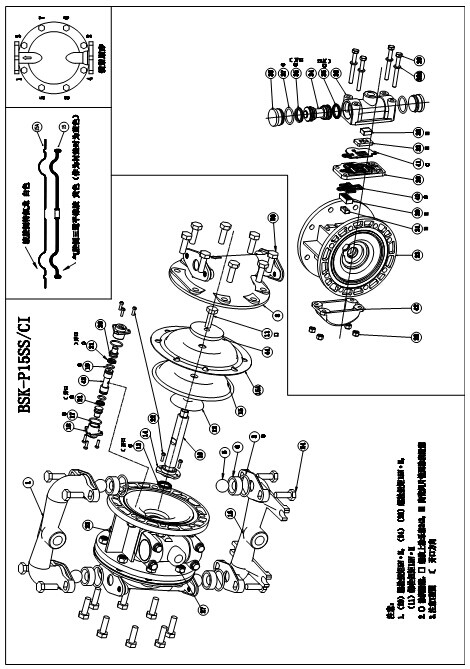

FLUID SECTION DISASSEMBLY

NOTE: Only diaphragm models use a primary diaphragm(6A) and a backup diaphragm(6). Refer to the aux iliary view in the Fluid Section illustration.

FLUID SECTION REASSEMBLY