QINGDAO ENNENG MOTOR CO.,LTD. |

|

Verified Suppliers

|

|

Product Description:

Architectural Feature:

| Frame size | 132 | 160 | 180 | 200 | 225 | 250M/L | 280M/L | ||||

| Mechanical Properties | |||||||||||

| Frame/End shield /Terminal boxes | Material | Cast Iron | |||||||||

| Mounting | B3/B35 | ||||||||||

| IP Grade | IP23 | ||||||||||

| Cooling Method | IC01(ODP) | ||||||||||

| Earth | Inside the wiring cover and the machine base | ||||||||||

| Bearing | Dust cover/clearance | ZZ/C3 | /C3 | ||||||||

| Bearing fix | DE fix, NDE with Wave spring washer | ||||||||||

| DE fix bearings | 3000rpm | 6308 | 6309 | 6312 | 6312 | 6313 | 6314/6318 | 6314/6318 | |||

| 1500rpm | 6308 | 6309 | 6312 | 6312 | 6313 | 6318/6318 | 6318/6318 | ||||

| NDE fix bearings | 3000rpm | 6308 | 6309 | 6312 | 6312 | 6313 | 6314/6316 | 6314/6316 | |||

| 1500rpm | 6308 | 6309 | 6312 | 6312 | 6313 | 6316/6316 | 6316/6316 | ||||

Lubrication | Material | ESSO UNIREX N2 | |||||||||

| Oil pipe | / | End shield oiling device | pipe | ||||||||

| plug | With rubber blind cover for transportation and storage | ||||||||||

| Shaft | Material | Steel45# | |||||||||

| B type | |||||||||||

| vibration limit (mm/s) | 1.6 | 2.2 | |||||||||

| Balance | 1/2 key G2.5 grade | ||||||||||

Nameplate | Material | Aluminum alloy | |||||||||

| Electrical performance | |||||||||||

| Voltage | 380/400V(or440/460V)three terminals | ||||||||||

Winding | Material | high purity copper | |||||||||

| Dipping method | VPI and drying | ||||||||||

| Insulation grade | 155(F) | ||||||||||

| Service Factor | 1.0/1.2/1.3 | ||||||||||

| stator and rotor lamination | silicon steel | ||||||||||

| permanent magnet | NdFeB | ||||||||||

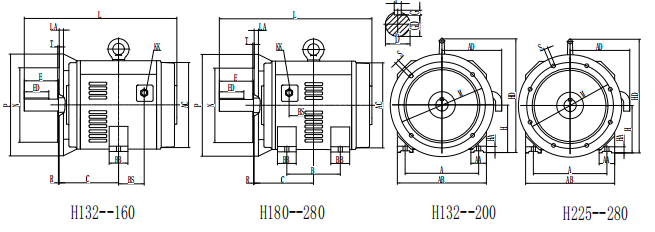

| B3/B35 size | Universal size | ||||||||||||||

| Frame size | A | AA | AB | B | BB | HA | H | K | C | AC | AD | BS | KK | L | |

| 3000rpm | 1500rpm | ||||||||||||||

| 132S | 216 | 63 | 270 | 140 | 190 | 20 | 132 | 12 | 89 | 275 | 213 | 0 | M33 | 508 | |

| 132M | 178 | 230 | 546 | ||||||||||||

| 160M | 254 | 73 | 320 | 210 | 274 | 20 | 160 | 15 | 108 | 330 | 260 | 65 | M33 | 659 | |

| 160L | 254 | 318 | 87 | 714 | |||||||||||

| 180M | 279 | 73 | 355 | 241 | 315 | 22 | 180 | 15 | 121 | 380 | 280 | 67 | M48 | 738 | |

| 180L | 279 | 355 | 86 | 778 | |||||||||||

| 200L | 318 | 73 | 395 | 305 | 375 | 25 | 200 | 19 | 133 | 400 | 305 | 86 | M48 | 820 | |

| 225S | 356 | 83 | 435 | 286 | 375 | 28 | 225 | 19 | 149 | 470 | 335 | 87 | M48 | 820 | |

| 225M | 311 | 400 | 100 | 845 | |||||||||||

| 280S | 457 | 93 | 550 | 368 | 490 | 35 | 280 | 24 | 190 | 547 | 400 | 158 | M64 | 985 | |

| 280M | 419 | 540 | 184 | 1035 | |||||||||||

| 315S | 508 | 120 | 635 | 406 | 575 | 45 | 315 | 28 | 216 | 645 | 530 | 162 | M75 | 1185 | 1215 |

| 315M | 457 | 685 | 188 | 1295 | 1325 | ||||||||||

| Universal size | B35/B5/V1size | ||||||||||||||||

| Frame size | D | E/DE | F | G | GD | N | M | P | S | T | R | LA | |||||

| 3000 rpm | 1500 rpm | 3000 rpm | 1500 rpm | 3000 rpm | 1500 rpm | 3000 rpm | 1500 rpm | 3000 rpm | 1500 rpm | ||||||||

| 132S | 38k6 | 80/70 | 10 | 33 | 8 | 230j6 | 265 | 300 | 15 | 4 | 0 | 14 | |||||

| 132M | |||||||||||||||||

| 160M | 42k6 | 110/80 | 12 | 37 | 8 | 250j6 | 300 | 350 | 19 | 5 | 0 | 15 | |||||

| 160L | |||||||||||||||||

| 180M | 48k6 | 110/80 | 14 | 42.5 | 9 | 250j6 | 300 | 350 | 19 | 5 | 0 | 15 | |||||

| 180L | |||||||||||||||||

| 200L | 55m6 | 110/80 | 16 | 49 | 10 | 300j6 | 350 | 400 | 19 | 5 | 0 | 17 | |||||

| 225S | 60m6 | 140/100 | 16 | 18 | 49 | 53 | 10 | 11 | 350j6 | 400 | 450 | 19 | 5 | 0 | 20 | ||

| 225M | |||||||||||||||||

| 280S | 65m6 | 75m6 | 140/100 | 18 | 20 | 58 | 67.5 | 11 | 12 | 450j6 | 500 | 550 | 19 | 5 | 0 | 22 | |

| 280M | |||||||||||||||||

| 315S | 65m6 | 80m6 | 140/100 | 170/140 | 18 | 22 | 58 | 71 | 11 | 14 | 550 | 600 | 660 | 24 | 6 | 0 | 25 |

| 315M | |||||||||||||||||

For textile enterprises, the energy consumption level of equipment has always been one of the most concerned indicators. In order to help save the total cost of textile factories, We have designed a new series of PM synchronous motors for knitting machines, which has been officially put on the market!

The PM synchronous motor has achieved IE5 and IE4 efficiency levels. With the expansion of production scale and production time, the energy efficiency gap between PM motors and normal motors will lead to huge cost differences.

The potential for wider adoption of permanent magnet motors in screw air compressors is immense and should not be overlooked. Here are a few key reasons why:

1. Energy Efficiency: Permanent magnet motors offer significantly higher energy efficiency compared to traditional induction motors. They have higher power density, reduced losses, and better control over speed and torque, resulting in lower energy consumption. This makes them an ideal choice for screw air compressors, which are known for their high energy requirements.

2. Improved Performance: Permanent magnet motors provide better speed control, allowing for precise adjustments to match air demand. This results in improved overall performance of the screw air compressor, ensuring optimal operation and reducing unnecessary wear and tear on the system. Additionally, the high power density of permanent magnet motors enables compact designs, saving valuable space in compressor installations.

3. Enhanced Reliability: Permanent magnet motors have a simpler construction with fewer moving parts, reducing the risk of mechanical failures. This leads to increased reliability and reduced maintenance requirements for screw air compressors. Moreover, these motors have a longer operational lifespan, resulting in lower replacement costs and downtime.

4. Environmental Benefits: The energy efficiency of permanent magnet motors translates to a significant reduction in carbon emissions. By adopting these motors in screw air compressors, industries can contribute to their sustainability goals and reduce their environmental footprint. This aligns with the growing global focus on green initiatives and the push towards more eco-friendly solutions.

5. Cost Savings: While the initial investment in permanent magnet motors may be higher than in traditional motors, the long-term cost savings outweigh the upfront expense. The energy savings achieved through their higher efficiency, combined with reduced maintenance and longer lifespan, result in substantial cost reductions over the lifetime of the screw air compressor.

In conclusion, the wider adoption of permanent magnet motors in screw air compressors offers numerous benefits, including improved energy efficiency, enhanced performance, increased reliability, environmental advantages, and long-term cost savings.