QINGDAO ENNENG MOTOR CO.,LTD. |

|

Verified Suppliers

|

|

IE5 Low-Speed Small Size Noiseless Permanent Magnet Ac Motor

What Is The Permanent Magnet Synchronous Motor?

The PERMANENT MAGNET SYNCHRONOUS MOTOR is mainly composed of the stator, rotor, chassis, front-rear cover, bearings, etc. The structure of the stator is basically the same as that of ordinary asynchronous motors, and the main difference between the permanent magnet synchronous motor and other kinds of motors is its rotor.

The permanent magnet material with pre-magnetized (magnetic charged) magnetic on the surface or inside the permanent magnet of the motor, provides the necessary air gap magnetic field for the motor. This rotor structure can effectively reduce the motor volume, reduce loss and improve efficiency.

Analysis of the principle of the technical advantages of permanent magnet motor

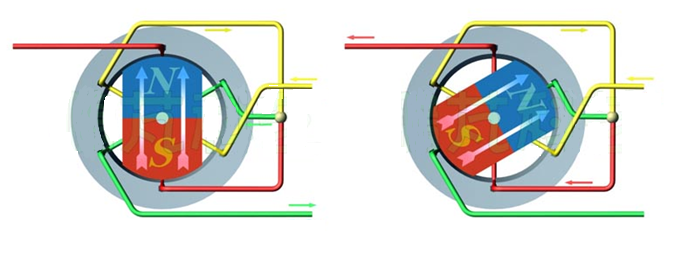

The principle of a permanent magnet synchronous motor is as follows: In the motor's stator winding into the three-phase current, after the pass-in current, it will form a rotating magnetic field for the motor's stator winding. Because the rotor is installed with the permanent magnet, the permanent magnet's magnetic pole is fixed, according to the principle of magnetic poles of the same phase attracting different repulsion, the rotating magnetic field generated in the stator will drive the rotor to rotate, The rotation speed of the rotor is equal to the speed of the rotating pole produced in the stator.

Due to the use of permanent magnets to provide magnetic fields, the rotor process is mature, reliable, and flexible in size, and the design capacity can be as small as tens of watts, up to megawatts. At the same time, by increasing or decreasing the number of pairs of rotor permanent magnets, it is easier to change the number of poles of the motor, which makes the speed range of permanent magnet synchronous motors wider. With multi-pole permanent magnet rotors, the rated speed can be as low as a single digit, which is difficult to achieve by ordinary asynchronous motors.

Especially in the low-speed high-power application environment, the permanent magnet synchronous motor can be directly driven by a multi-pole design at low speed, compared with an ordinary motor plus reducer, the advantages of a permanent magnet synchronous motor can be highlighted.

Benefits of PMSM motors:

High efficiency

This is particularly true at lower speeds. The permanent magnet

motor does not require current to be supplied to its rotor to

generate the rotor field, therefore eliminating the rotor losses

almost completely. When compared to induction or reluctance motors

it also requires lower currents on the stator and has a bigger

power factor, leading to smaller current ratings on the controller,

and increasing the overall drive system efficiency.

Driving lower speeds at higher efficiency than an induction motor might delete the requirement of a speed-reduction transmission, taking the complexity out of the mechanical arrangement.

Constant torque

This type of motor can generate constant torque and maintain full

torque at low speeds.

Size

The smaller size, lighter weight, and less coil provide a higher

power density.

Cost-effective

With the absence of brushes, there are reduced maintenance costs.

Minimal heat

In PMSM the heat is generated on the stator coils and there are no

brushes and only minimal heat generated on the rotor, facilitating

the cooling of the motor. As they run cooler than induction motors,

the motor's reliability and lifespan are increased.

Speed range

This type of motor can have a wide speed range with the use of

Field Weakening and can adopt the maximum torque/current (MTPA)

control strategy during constant torque operation.

Energy saving principle of permanent magnet synchronous motor:

1 High efficiency: Compared with Y2 series motors, the average power saving is over 10%. Generally, when the efficiency of asynchronous motors is below 60% of the rated load, the efficiency will drop quickly, and the efficiency will be very low at light load; the efficiency of asynchronous motors will drop quickly with the decrease in speed, so the efficiency of asynchronous motors is very low at low speed and low load. TYP series high-efficiency permanent magnet variable frequency synchronous motors are in the high-efficiency zone at 20%~110% rated load. According to field measurements by multiple manufacturers under different working conditions, the energy-saving rate of high-efficiency permanent magnet variable frequency synchronous motors is between 10% and 40%.

2 The power factor is high, and the actual measured value in the rated state is close to the limit value of 1.0, which is above 0.95. The power factor curve and efficiency curve of the TYP series high-efficiency permanent magnet variable frequency synchronous motor are high and flat; the power factor is high and the stator current is small, thereby reducing the stator copper consumption. Improve efficiency.

3 Small current: Because this series of motors adopt a built-in rotor magnet structure with a certain salient torque, and then adopt the maximum torque/current ratio control method, the motor has a higher power factor in the full speed range. , The motor current drops significantly. According to actual measurements, the stator current value of the high-efficiency permanent magnet variable frequency synchronous motor can be reduced by 15% to 30% compared with the asynchronous motor, and the motor current is greatly reduced, reducing the loss in cable transmission, which is equivalent to expanding the capacity of the cable.

4 Running without slip, stable speed: TYP series high-efficiency permanent magnet variable frequency synchronous motors are synchronous motors. The speed of the motor is only related to the frequency of the power supply. The speed of the motor is synchronized with the speed of the stator rotating magnetic field. It is not affected by voltage fluctuations and load size. Lost rotation, no slip, no slip power loss, thereby improving efficiency and control accuracy.

5 Low-temperature rise 15~20℃: Because the high-efficiency permanent magnet variable frequency synchronous motor has high efficiency and low loss, the temperature rise is low. Through actual measurement, under the same conditions, the operating temperature of the high-efficiency permanent magnet variable frequency synchronous motor is 15-20℃ lower than that of the asynchronous motor.

Permanent magnet AC (PMAC) motors have a wide range of applications including:

Industrial Machinery: PMAC motors are used in a variety of industrial machinery applications, such as pumps, compressors, fans, and machine tools. They offer high efficiency, high power density, and precise control, making them ideal for these applications.

Robotics: PMAC motors are used in robotics and automation applications, where they offer high torque density, precise control, and high efficiency. They are often used in robotic arms, grippers, and other motion control systems.

HVAC Systems: PMAC motors are used in heating, ventilation, and air conditioning (HVAC) systems, where they offer high efficiency, precise control, and low noise levels. They are often used in fans and pumps in these systems.

Permanent magnet synchronous motors with internal magnets: Maximum energy efficiency

The permanent magnet synchronous motor with internal magnets (IPMSM) is the ideal motor for traction applications where the maximum torque does not occur at maximum speed. This type of motor is used in applications that require high dynamics and overload capacity. And it is also the perfect choice if you want to operate fans or pumps in the IE4 and IE5 range. The high purchase costs are usually recouped through energy savings over the run time, provided that you operate it with the right variable frequency drive.

Our motor-mounted variable frequency drives use an integrated control strategy based on MTPA (Maximum Torque per Ampere). This allows you to operate your permanent magnet synchronous motors with maximum energy efficiency. The overload of 200 %, the excellent starting torque and the extended speed control range also allow you to fully exploit the motor rating. For fast recovery of costs and the most efficient control processes.

Permanent magnet synchronous motors with external magnets for classic servo applications

Permanent magnet synchronous motors with external magnets (SPMSM) are ideal motors when you need high overloads and rapid acceleration, for example in classic servo applications. The elongated design also results in low mass inertia and can be optimally installed. However, one disadvantage of the system consisting of SPMSM and variable frequency drive is the costs associated with it, as expensive plug technology and high-quality encoders are often used.

Renewable Energy Systems: PMAC motors are used in renewable energy systems, such as wind turbines and solar trackers, where they offer high efficiency, high power density, and precise control. They are often used in the generators and tracking systems in these systems.

Medical Equipment: PMAC motors are used in medical equipment, such as MRI machines, where they offer high torque density, precise control, and low noise levels. They are often used in the motors that drive the moving parts in these machines.

1 The operating environment should always be kept dry, the surface of the motor should be kept clean, and the air inlet should not be obstructed by dust, fibers, etc.

2 When a protection alarm occurs, the cause of the failure should be found out, and the operation can only be put into operation after the failure is eliminated.

3 When the machine is stopped for inspection, the operation can only be carried out after the motor has completely stopped.

4 In order to ensure good lubrication of the motor during operation, the motor should run for about 4000 hours, that is, the grease should be supplemented or replaced (the closed bearing does not need to be replaced during the service life). When the bearing is found to be overheated or the grease is deteriorated during operation, The grease should be replaced in time. When replacing the grease, remove the old grease and clean the oil grooves of the bearings and bearing caps with gasoline. For motors with a speed of 1500r/min and below, refill the bearing grease type for medium and small motors bearing grease No. 2, and fill the inner and outer rings of the bearing About two-thirds of the gap between the bearings; the motor speed of 2500r/min and above is filled with bearing grease type HTHS, which fills about one-half of the gap between the inner and outer rings of the bearing.

5 When the life of the bearing is over, the vibration and noise of the motor will increase obviously. Check that the radial clearance of the bearing reaches the value in the table below, and the bearing should be replaced.

6 Maintenance of TYP series high-efficiency permanent magnet variable frequency synchronous motors requires qualified units or personnel who understand the precautions for TYP series high-efficiency permanent magnet variable frequency synchronous motors.

7 When disassembling the motor, the rotor can be taken out from the shaft extension end or the non-shaft extension end. If it is not necessary to remove the fan, it is more convenient to remove the rotor from the non-shaft extension end. When extracting the rotor from the stator, prevent damage to the stator winding or insulation.

8 When replacing the winding, the form, size, number of turns and wire gauge of the original winding must be noted. Random replacement of the original design windings often deteriorates one or several performances of the motor, or even cannot be used at all.