Changzhou TIANNIU Transmission Equipment Co., Ltd |

|

Verified Suppliers

|

|

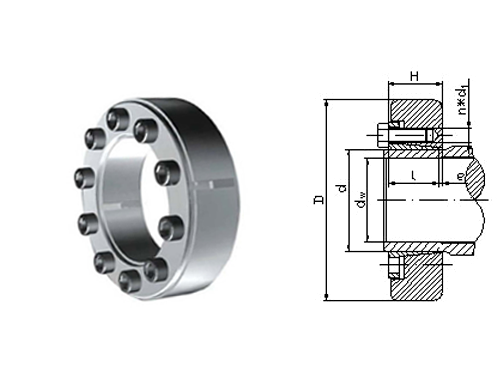

Z10-50*90 Locking Device Shaft Locking Assembly

Products Features

Axial positioning of ultra-precision angular contact ball bearings on the shaft or in the bearing seat usually adopts locking nuts or end caps. These locking assembly require high geometric accuracy and good mechanical strength to provide stable support and positioning.

Special attention should be paid to the sequence of installation when mounting the locking assembly beyond the sprag clutch bearing. Precision bearings should also pay attention to the positive and negative ends. If they are installed in reverse, dynamic imbalance will be caused and the performance of bearings will be affected.

Fault and treatment

The repair is mainly divided into the following steps: first, the worn parts of the journal and the inner hole of the gear are treated to be clean, dry and rough, and the primary metal color is exposed. The surface of the shaft diameter is coated with polymer metal repair material 2211f, scraped with a ruler and solidified; The surface of the inner hole of the gear shall be treated, and the polymer metal repair material shall be applied to smooth and solidify the wear trace; After the material is heated and solidified, the surface of the material is polished and leveled, and the inner ring of locking assembly is used as the mold.

Due to the long-term transmission of large torque in the work, the expansion sleeve is easy to cause metal fatigue deformation, resulting in fatigue wear between the expansion sleeve and fasteners. At the same time, due to the large sintering machine, it is difficult to repair. To solve these problems, polymer composites can be used for on-site repair. The matching relationship between parts and the running state and wear of equipment generally has the corresponding relationship between parts and mold repair process.

Fit the repaired part of the shaft diameter surface with the size, polish the foot edge, and then measure the repaired size; Finally, the inner and outer rings of the locking assembly are coated with polymer metal repair materials for general assembly.

Products Parameters