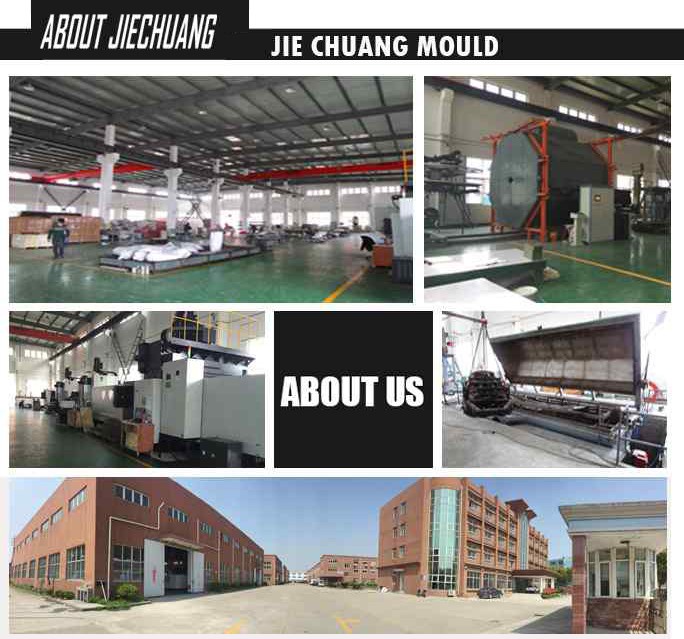

Shanghai Jiechuang Mold Manufacturing Co., Ltd. |

|

| ||||||||||||||||

| ||||||||||||||||

|

|

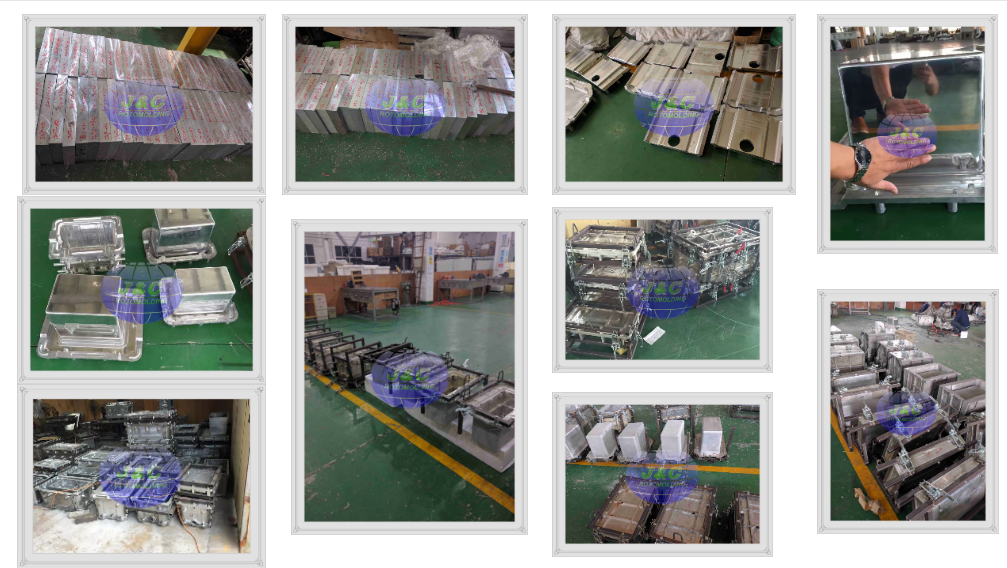

We can make any kinds of rotomold ,according to your design , we have many

years experience making aluminium rotomoulds , can make sure that there is no porosity in the mould, if you want to develop your own moulds ,just send us your design , if you have your design , you can just send us your sample, we can design the mould drawing for you .

From concept to final product, everything is done in-house, including making prototypes and designing and manufacturing moulds.

Rotational molding has particular advantages in terms of relatively low levels of residual stresses and inexpensive molds. Rotational molding also has few competitors for the production of large (> 2 m3) hollow objects in one piece. Rotational molding is best known for the manufacture of tanks but it can also be used to make complex medical products, toys, leisure craft, and highly aesthetic point-of-sale products.

Roto Advantage

Design flexibility allowing complex geometry

· Cost saving - Projects of 50 to 30,000 are ideal

· Molds cost less then other molding methods

· Parts offer strength and durability

· Stress free parts

· Short lead times on production

· Consistent wall thickness

· Limited materials waste

· Small to very large hollow parts can be produced

· Part surfaces can have various textures

RFQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 35 days after confirming drawing and receive advanced payment.

Q: Do you provide samples once open mould?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 50% advanced payment, the balance before shippment.