alum A356 rotational mold for plastic shell of sanitary equipment

and floor cleaning machine

Rotational moulding, known also as rotomolding or rotocasting, is a

process for manufacturing hollow plastic products. For certain

types of liquid vinyls, the term slush molding is also used.

Rotational molding has particular advantages in terms of relatively

low levels of residual stresses and inexpensive molds. Rotational

molding also has few competitors for the production of large (>

2 m3) hollow objects in one piece. Rotational molding is best known

for the manufacture of tanks but it can also be used to make

complex medical products, toys, leisure craft, and highly aesthetic

point-of-sale products.

Product Description

Poduct Name | alum A356 rotational mold for plastic shell of sanitary equipment

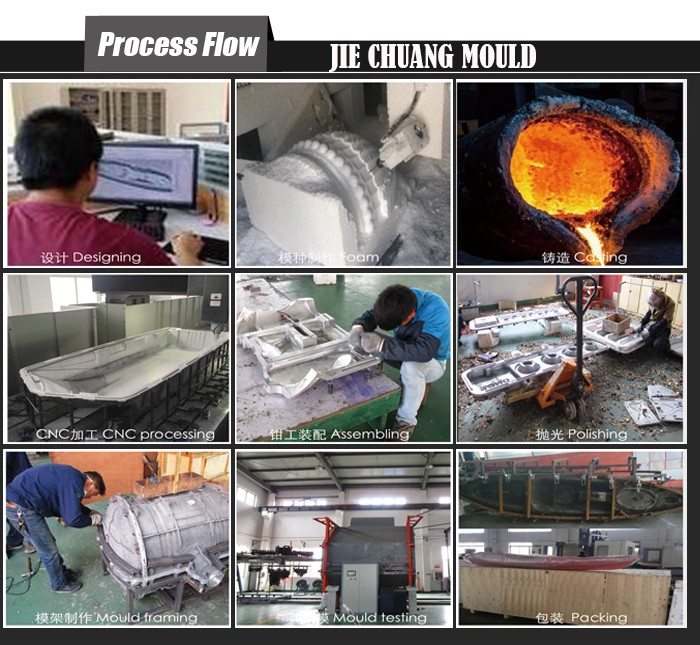

and floor cleaning machine | Material | Aluminum A356 | Surface treatment | Polish, Sandblasting, Telfon coating | Wall thickness | 8-10mm | Mould life | Over 10000 shots | Mould Process | Design, foam, casting, CNC process, Polish, Frame, Test, Packing | Platic Material | LLDPE, MDPE, HDPE, CROSS LINKED PE | Our service | help you design with our professional experience for rotational

mold |

|

| |

| | |

Advantages of our Rotomolding:

1) Economic tooling costs.

2) One-piece construction.

3) Weight reduction-as compared to most metals.

4) Uniform wall thickness-nothinning in the extremites.

5) Thickness can be varied if required

6) Variety of finishes and color.

7) The ability to produce multi-wall moldings.

8) Design flexibility-from small and intricate to large and

complex.

9) Metal inserts as integral parts.

10) Short lead-time.

11) Resistance to stress-cracking and corrosion.