Shanghai Jiechuang Mold Manufacturing Co., Ltd. |

|

| ||||||||||||||||

Step1

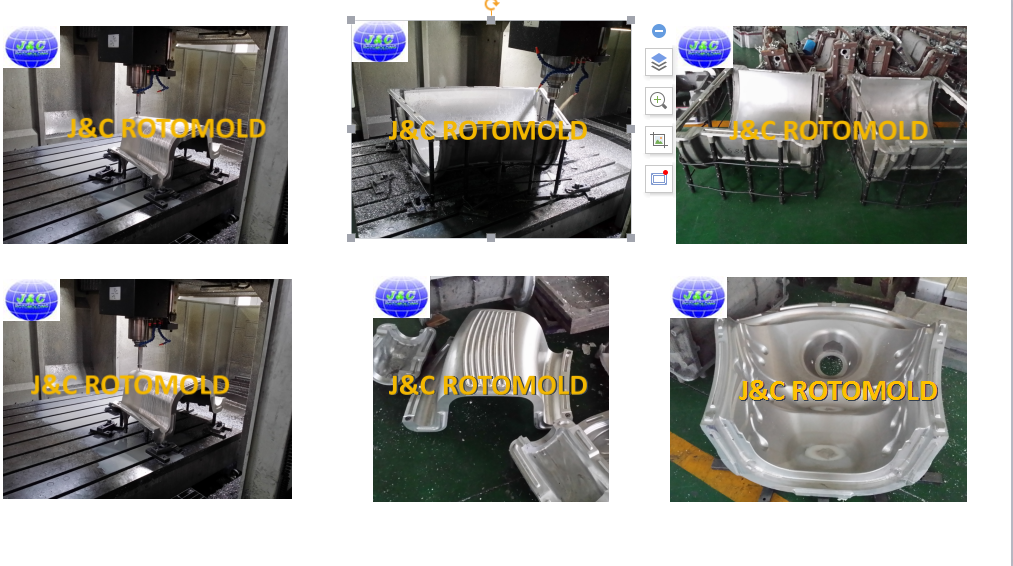

Plastic raw material (typically in powder form) is placed inside a

mold (cast aluminum, CNC machined aluminum)

Step2

The mold is attached to an arm of a rotational molding machine, and

enters the oven where it rotates (rotational molding) on two axes.

Step3

As the plastic material melts, it begins to adhere to the inside

mold walls, building wall thickness and taking on the shape and

texture of the interior mold surface.

Step4

After rotating in the oven, the mold enters the cooling phase,

where the molten material eventually solidifies into the finished,

hollow plastic part.

Step5

The part is then removed from the mold, where it undergoes a

variety of secondary operations (trimming, foam-filling, assembly,

etc.) prior to shipment.