Dongguan Howe Precision Mold Co., Ltd. |

|

Verified Suppliers

|

|

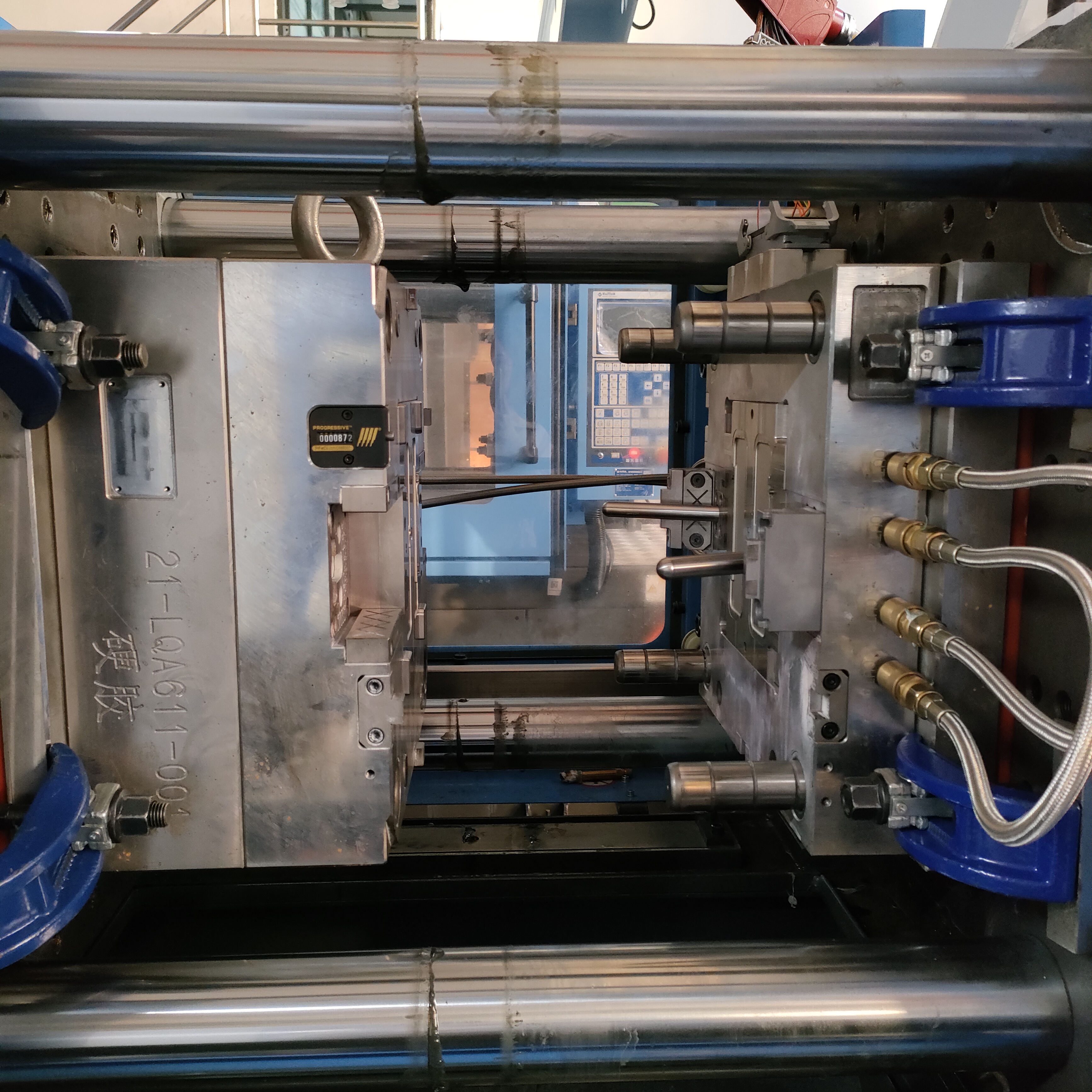

Manufacturer Creat Plastic Injection Mold With Side Gate Type

| Items | Description |

| Mould Core | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 etc. |

| Hardness of steel | 46~56 HRC |

| Molud Standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

| Mould Base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

| Cavity | Single/Multi |

| Runner | Hot/Cold Runner |

| Maximum Mould Size | 1800*1200*800 mm |

| Surface of Mould | EDM / High Polish&Texture |

| Plastic material | PP, PC, PS, PE, PET, POM, PA,PU, PVC, ABS,HIPS, PMMA etc. |

| Mould Life | 300,000-1,000,000 shots |

| Specification | Depends on customer’s requirements. |

| Surface Treatment | Polish,texture,painting,screen printing,turnkey project |

| Trade terms | FOB Shenzheng,EXW , FOB, CIF |

| Export to | Europe countries,USA,Mexico,Australia ,Middle-east ,Asia etc |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point gate, side gate, subgate, tunnel gate,banana gate, direct gate ,etc. |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Surface finish of Part | Logo print,Texture,Polishing,Painting,Chrome Plating |

| Delivery time | 20-35 Days |

| Outside package | Standard wooden casesor as your requirement |

| Inner package | Stretch waterproof film & Each Mold painted ,anti-rust oil.3. Spare parts together with the mold shipment. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

How to order from HOWE?

1. Inquiry-Professional quotation.

2. Confirm the price. lead time. artwork. payment term etc.

3. Howe sales send the Proforma Invoice with Howe company seal.

4. Customer make the payment for deposit and send us Bank receipt.

5.Initial Production Stage-Inform the clients that we have got the

payment and will make the samples according to your request, send

you photos or Samples to get your approval. After approval, we

inform that we will arrange the production & inform the

estimated time.

6. Middle Production-send photos to show the production line which

you can see your products in . Confirm the estimated delivery time

again.

7. End Production-Mass production products photos and samples will

send to you for approval. You can also arrange the third party

Inspection .

8. Client make payment for balance and Howe ship the cargo. Also

Howe can accept payment term-Balance against TT,Paypal or D/P

payment Term.

9. Order can be say "finish" when you receive the goods and satisfy

with them .

10. Feedback to Howe about Quality. Service. Market Feedback &

Suggestion. And we can do better .

Sample Showroom

FAQ About plastic injection moulding parts

Q1: How many injection plastic mouldings machines do you have?

A1: We have 40 sets of plastic Injection Mouldings machines.

Q2: what are the minimum & maximum unit weight and size your

machines can produce?

A2: Our machines produce unit parts from 1 gram to 6000 grams of

weight.

Our machines can produce the maximum size of unit plastic part:

1.5*1.5*1.5 meters.

Q3: What kind of plastic materials you usually use?

A3: We are specialized in producing plastic products with the

following materials:

PP, ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so on.

Q4: How do you pack the plastic molded parts?

A4: We pack the plastic molded parts by thick-wall cartons.

If the finished surface of plastic molded parts requires safe

protection to avoid scratches, we will use a bubble plastic bag to

pack the parts.

FAQ About Worldwide Delivery

Q5: Can you deliver the plastic moulds or plastic products to our

factory?

A5: Yes, We have cooperated with many international logistics

companies for years.

And we have full experience to manage the delivery directly to the

client's factory or appointed warehouse.