Dongguan Howe Precision Mold Co., Ltd. |

|

Verified Suppliers

|

|

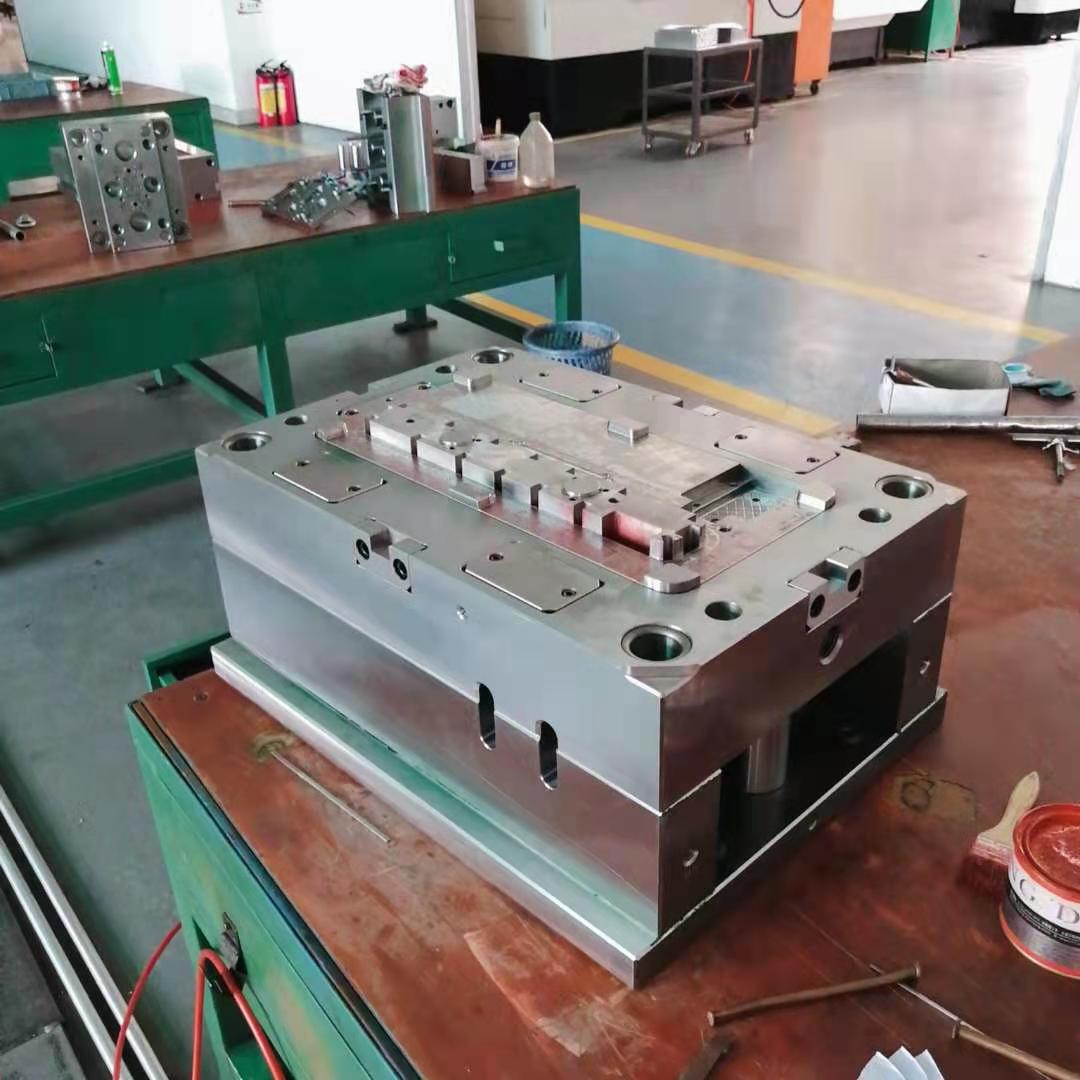

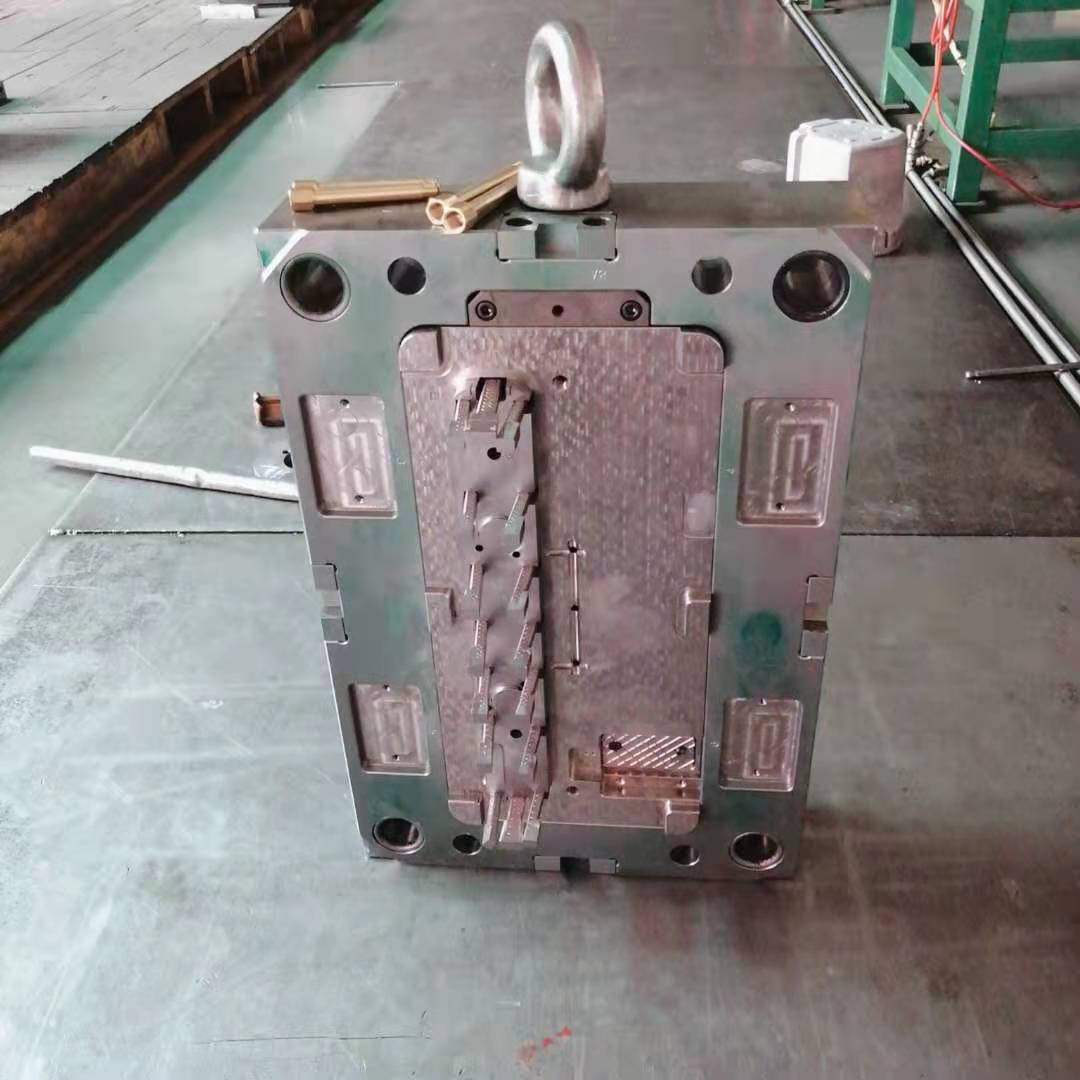

Customized 1.2311 4 cavity mold for plastic injection moulding products

Mold Information:

Name | Plastic Injection Mould |

Brand Name | HOWE MOULD |

Mould Material | P20/718/738/NAK80/2738/2316/S136/...etc |

Product Material | ABS/PP/PC/PE/PA/POM/NYLON...etc |

Runner | Hot Runner/Cold Runner |

Mould Weight | 50kg-15Ton |

Standard | ISO9001:2008 |

Our Service | Plastic Injection Mould Manufacturing/Die-casting Mould

Manufacturing/OEM assembling |

| Mass-produced plastic parts and aluminium die castings parts with mould as tools | |

Applications | Aviation, aerospace, Medical care,electronics, computers,

machinery, ships, automotive industry, household appliances,etc |

| communications, light industrial products, gifts, toys, plastic products, sports and leisure. | |

Size | Customized |

Color | Customized |

About Us

Howe is a company specializing in the design and manufacture of

high-quality plastic injection molds and injection molded parts for

the international market and Have been engaged in the manufacturing

sector since our inception.Is an OEM/ODM factory, customized your

products to meet your needs is our advantage, We are managed by a

group of professionals with many years of experience in mold

design, molding technology and Quality control. We have developed

an excellent understanding of the technical and quality

requirements needed. We build tools to fit your expectations and

match your quality standards.Our team of CAD designers will ensure

that your imagination is incorporated into the actual product! If

you want to create prototype or mass-produce in a very specific

project, we can help you achieve your vision!

Mould Trade Process

Quote: According to sample, drawing and specific requirement.

↓

Discussion: Mold material, cavity number, price, runner, payment, etc.

↓

S/C Signature: Approval for all the items

↓

Advance Pay: 40% by T/T

↓

Product Design Checking: We check the product design. If some position is not perfect, or

can not be done on the mould, we will send customer the report

↓

Mold Tooling: We start to make mold after mold design confirmed

↓

Mold Processing: Send report to customer once each week

↓

Mold Testing: Send trial samples and try-out report to customer for

confirmation.

↓

Pay :30% by T/T on trial samples

↓

Mold Modification: According to customer's feedback

↓

Balance settlement: 30% by T/T after the customer approved the trial sample and mould

quality.

↓

Delivery: Delivery by sea or air. The forwarder can be designated by your

side.

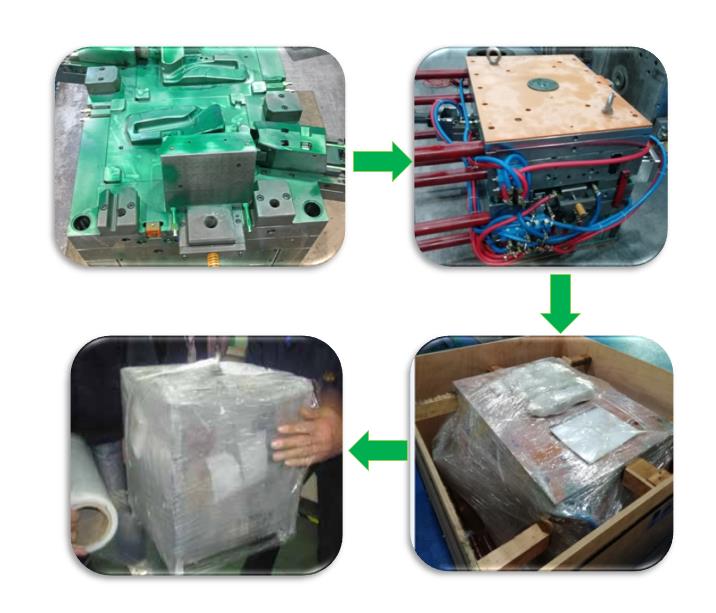

Package

Mold package:

Product package:

Frequency Asked Questions

Q1: Are you manufacturer or trading company ?

A1: We are the manufacturer of Injection moulding parts, our price

is more competitive.

Q2: Do you support OEM/ODM service?

A2: Yes, we have a large experienced R&D team, we can offer

one-stop service,so welcome to place OEM/ODM orders to us.

Q3: How long is the lead-time for a plastic injection mold?

A3: It all depends on the mold’s size and complexity.Normally, the

lead time is 25-45 working days.If the plastic moulds are very

simple and in small size, we can work out within 15 days.

Q4: What kind of plastic materials you usually use?

A4: We are specialized in producing plastic products with the

following

materials:PP,ABS,PC,POM,PA,HDPE,HIPE,PS,AS,PBT,PET,PMMA,PVC and so

on.

Q5: How do you pack the plastic molded parts?

A5: We pack the plastic molded parts by thick-wall export

cartons.If the finish surface of plastic molded parts requires safe

protection to avoid scratches, we will use bubble plastic bag to

pack the parts.

Q6: How does your factory do regarding quality control?

A6: Secure production under strict quality control system; Quality

is priority. 100% products tested. CE/ ROHS FCC/ Certification are

available if required.