Dongguan Howe Precision Mold Co., Ltd. |

|

Verified Suppliers

|

|

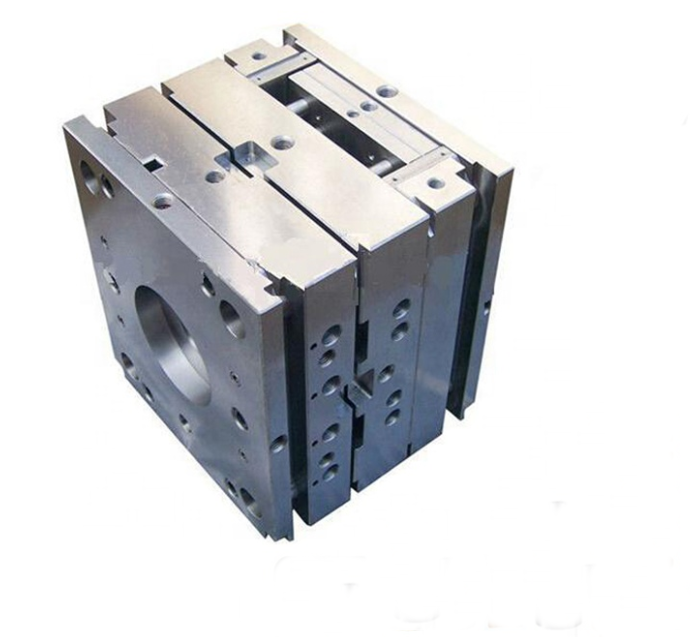

Double shot plastic injection moulding electronic plastic parts OEM manufacture High volume

Mould Information:

| Plastic injection Mould standard | HASCO, DME, MEUSBURGER, JIS, CHINA LKM STANDARD |

| Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ) |

Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| Hardness of steel | 46~56HRC |

Material for Slider, Lifter and all sub insert use | 1.2767 HRC |

| Cavity | Single-cavity, Multi-cavity |

| A surface request | EDM & High Polish |

| Gate | Cold runner, Yudo/DME/HASCO/Synventive Hot runner |

Mould lifetime | 500000~+1,000,000 shots |

| Quality | ISO9001-2008 certification |

| Process of making moulds | |

| 1.Sample/Drawing | After receiving your detail information like 2D & 3D drawings or sample for reference, will pass to the R&D team to do Moldflow analysis. |

| 2.Negotiation | Material, cavity, price, delivery time, payment term etc. |

| 3.Place Order | when all terms are agreed by both sides, then we will accept an order. |

| 4.Mould Design | Our R&D team will design the mould per customer requirements and send drawings for approval. |

| 5.Tooling Mould | Once the mould design is approved will start mould tooling. |

| 6.Mould Process | CNC grinding and milling, Heat Treatment, Wire Cut, Polish, Tool assembling and testing etc. Our good QC system can guarantee the product quality. |

| 7.Sample Confirmation | Send samples for confirmation, if not approved we will adjust the mould structure. |

| 8.Mass Production | After the customer approves the sample, we will arrange mass production. QC will inspect after products finished. |

| 9.Package | PE film for plastic parts, wooden case for moulds or as customer's requirement. QC will inspect packing. |

| 10.Delivery | By sea or by air according to customer requirement. |

| 11.After-sales Service | Ready to help customers solve any possible problems. |

Surface finish:

| Aluminum parts | Stainless Steel parts | Steel | Plastic |

| Clear Anodized | Polishing | Zinc plating | Painting |

| Color Anodized | Passivating | Oxide black | Chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | polishing |

| Chemical Film | Laser engraving | Chrome plating | Sandblast |

| Brushing | Carburized | Laser engraving | |

| Polishing | Heat treatment | ||

| Chroming | Powder Coated |

Our advantage

1. The capacity of Research and Development

Howe has a powerful team for research and development, which is

capable of manufacturing the injection and die-casting molds with

one cavity to Multi- cavities. At the same time, we can manufacture

perform molds especially according to customers' injection molding

machines. We also have the service to manufacture the products by

the moulds, such as electronic enclosures, junction boxes, tool

case, equipment case, plastic parts,etc..

2. Advanced Processing Equipment

Many machine tools are imported from America and Japan, such as

Machine center, CNC lathers, EDM and so on. All of these

increase processing precision, good interchangeability, and

low eccentricity.

3. Perfect Inspection Method

Inspection tools include projector, hardness tester, stress tester,

eccentric tester, electric balance, and other inspection tools.

The screw neck is made and inspected strictly by the standard of

Coca-cola and the screw neck has been up to the standard of

Coca-cola.

4. After-Sales Service

Technologists professional in after-sales line and excellent credit

assures stable operation