Dongguan Howe Precision Mold Co., Ltd. |

|

Verified Suppliers

|

|

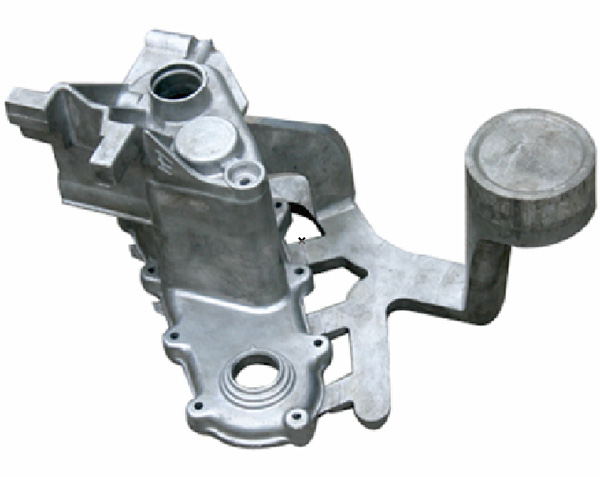

aluminum foundry aluminium die casting parts

Mould Information:

| Common Raw Material | K-Alloy, AlSi12Cu, ADC12, A380 Or Other Special Aluminum Raw Material |

| Surface Treatment | Powder Coating, Coating, Plating, Anodizing, PVD, Copper Plating, etc. |

| Machine Type | 150T, 280T, 350T, 400T, 600T, 800T, 1200T |

| Producing Process | Die-Casting, Degating, Deburring, Grinding, Polishing, Punching Hole, Drilling, Tapping, Machining, Milling, Cleaning, Finishing, Full Checking |

| Quality Control | We Control Our Product Quality Strictly From Raw Material Coming To Ship Our Finished Goods. |

| Shipping Method | For Mass Production, Usually By Sea, Sometimes, By Air If Need Urgently; For Small Samples, Usually By Express. |

| Quotation Elements | We Can Know The Basic Information Including Raw Material, Surface Treatment, Key Dimension From PDF And 3D Product Drawing; Also, It Is Better TO Know Application, Estimated Annual Usage Or Other Special Requirements. |

| Technical Analysis | We Need To Do The Deep DFM Analysis Before We Start To Our New Project Officially, Which Contains Product Feature Confirm, How To Make The Mold, etc. |

| Molding Leadtime | Usually, 28-35 Days; However, We Can Adjust This Leadtime If Need. |

| Available Material (metals) | Available Material (plastic) |

| Alloy (aluminum, zinc, magnesium, titanium) | ABS, PC,ABS, PMMA (acrylic), Delrin,POM |

| Brass, bronze, beryllium, copper | PA (nylon), PP, PE, TPO |

| Carbon steel, stainless steel, SPCC | Fiberglass reinforced plastics, Teflon |

| Processes | Surface treatment (finish) |

| Casting, CNC machining(Milling/Turning), Grinding | High polish, brush, sandblast, anodization |

| Sheet metal stamping, bending, welding, assembly | plating (nickel, chrome), powder coat, |

| Punching, Deep drawing, Spinning | Lacquer painting, silkscreen, pad printing |

| Equipment | Quality control |

| Casting machines, CNC machining centers (FANUC, MAKINO) | CMM (3D coordinate measuring machine), 2.5D projector |

| CNC turning centers/ Lathes / Grinders | Thread gauge, hardness, caliber. A closed-loop QC system |

| Punching, Spinning and Hydraulic tensile machines | Third-party inspection available if required |

| Lead time & Packing | Application |

| 7~15 days for sample, 15~25 days for production | Automotive industry / Aerospace/ Telecom equipment |

| 3~5 days via express: DHL, FedEx, UPS, TNT, etc. | Medical / Marine / Construction / Lighting system |

| Standard export carton with pallet. | Industrial Equipment & Components, etc. |

stainless steel: ss304,ss304L,ss316,ss316L,SS430,SS201......

aluminium: 7075,6061,6063,5082,5051,2014.......

brass: H62,H58,H59......

steel: C20,C45,C60,C35......

steel alloy: 25CrMo,42CrMo,25Cr,40Cr,Q345,11SMn30......

iron cast: QT600,QT250,HT450,HT150......

titanium alloy: GR2,GR5,GR7,GR9......

tungsten alloy: WuNiFe alloy,Carbide Wolfram......

the plastic: POM,PC,PE,PVC,ABS,DELRIN,ACRYLIC......

the blanks: forging,casting,profile,extrusion,rod,tube......

One-stop Service

We offer a one-stop service from module design till finished products, make every customer happy.

Skillful salesgirl and diligent salesman make business heathier and Win-Win.

Superior Quality

Strict quality control system, we care about each customer’s needs.

Professional R&D team in whole processes supporting the

business.

Advanced machine and inspection equipment to satisfy the request of

order.

Professional After-sales Service

Mature supplier chain with cooperative team production management, lead to an outstanding offer.