Dongguan Howe Precision Mold Co., Ltd. |

|

Verified Suppliers

|

|

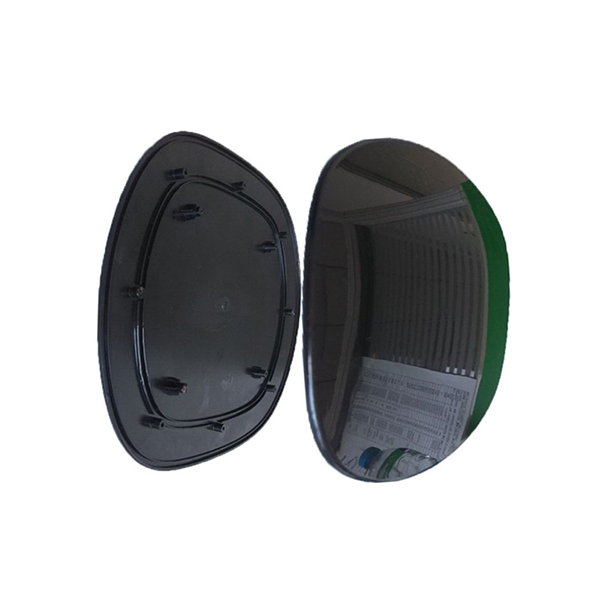

Carriable wireless ABS speaker cover plastic injection moulding

Mould Information:

| Material | Various plastic material including ABS, AS, PPS, PP, POM, EVA, PC, PA, PMMA, PS, TPE, TPU, TPR, and other injected plastic material. |

| color | OEM |

| Packaging | Inner packing--Polythene bags, outer packing--Paper cases suitable for transportation by air or sea |

| Application | All kinds of plastic injection parts being used in a variety of applications including home use, industrial use and so on |

| Machines | Different injection machines to meet your needs of manufacturing different products |

| Finish | Vacuum plating, electroplating, painting, printing, texture and so on |

| 1 | Mould base material | LKM,HASCO,LOCAL ,DME, etc |

| 2 | Mould core material | 718H, S136H, NAK80, P20, etc |

| 3 | Plastic molded parts material | ABS, ABS+PC, PC, PP, PVC, |

| 4 | Cavity | Single, Multi |

| 5 | Runner | Hot & Cold Runner |

| 6 | Gate | Pin-point gate, Edge gate |

| 7 | Finish | Semi-Matt, Polish |

| 8 | Design software | Pro-E, IGES, UG, CAD CAXA, etc |

| 9 | Main processing equipment | CNC, Cutting, Carved, Milling, EDM |

| 10 | Arrangement type | I-section, Straight body mould |

| 11 | Second Processing | Silk-scree Printing, Plating, Painting |

| 12 | Package | Wooden case for mould, carton box for Plastic injection products |

| 13 | Delivery time | 30-40 days for mould and samples. 7days for mass production of Plastic injection molding inc. |

| 14 | Trade Term | Ex-works, FOB Shenzhen, CIF |

| 15 | Payment Term | Mould: 50% paid by T/T in advance, balance 50% paid after confirming samples Mass production: 50% paid by T/T in advance, balance 50% paid before loading. |

Plastic Mold (Mould) production process:

1. 3d Design/Samples for quotation: According to 3D drawing or samples for quotation.

2. Negotiations: Including the price of molds, molds sizes, material for cores & cavities, the weight of the product, product color, payment, molds lifetime, delivery, etc.

3. Purchasing Order: After the customer confirming the mold design and quotation.

4. Making mold(mould): Confirm drawing, start to do DFM, mold flows and mold detail agreed with the customer, start production.

5. Production schedule: Every week we will feedback to the customer about the mold progress(picture).

6. Sample shoot: We provide the molds test samples for confirmation(about 10-15 pieces), we will start mass production when getting your signature samples.

Function

Insert the SD card / USB to play music

Built-in TF/USB, you can listen to MP3 music stored in TF

card/USB

AUX Input plug

While working with AUX, it is easy to listen to sound from PC,

Mobile phone, MP3/MP4

Bluetooth

Work with the Wireless Bluetooth to play music

Karaoke

Two microphone holes support two people singing songs

together.

FAQ

1. Q: What type of mould you can make?

A: We can make all kinds of plastic injection moulds.

2. Q: What type of steel do you use?

A: 2738, NAK80 , 718H, H13, 2344, S136, P20(H), 4Cr13, S55C,C45#,

etc.

3. Q: what kind of material do you use?

A: ABS, PP, PC, PE,HDPE,POM, PA6, PA66, PA6+GF, PS, PMMA, TPU, TPE,

PVC, SMC, BMC, etc. We have rich experience for molding product

with these materials and know how to adjust Parameter to get the

perfect product.

4. Q: How to send a sample?

A: The quotation we offer to you including the cost of sample

delivery 1-2 times. We send sample by DHL, UPS, EMS,FEDEX or TNT.

5. Q: Can you deliver of the samples ( Free or Paid)

A: Yes, if no order, ask for the sample is paid.