Ningbo Hopesun Machine Co., Ltd. |

|

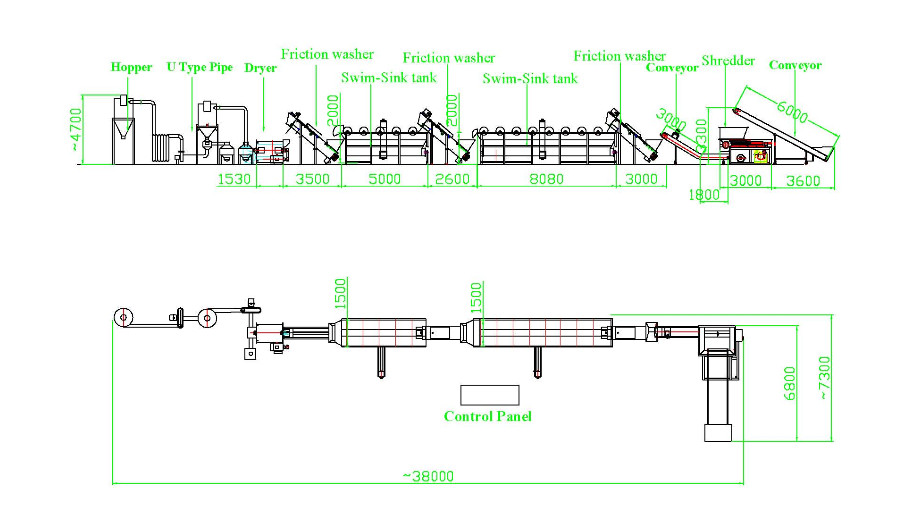

PP LDPE Plastic Film Recycling Machine With Capacity 500 Kg /Hr

Description:

1. Debaler: As PP/PE films often arrive at washing facilities in baled form, films such as LDPE / LLDPE are compacted in large bundles tied together, bales must first be opened before it can enter the washing equipment. This can be done either manually or via the debaler.

2. Plastic crusher: The plastic granulator cuts PP / PE films into small pieces. The size reduction process is essential in our PE film washing line as long pieces of plastic film can easily tangle in conveyor and rotary-based equipment such as those used in the washing line. To prevent this from happening, the plastic granulator cuts the PP / PE film into pieces that are approximately 10-20mm in size. To further improve this process, we’ve implemented the use of a wet granulator where water is continuously sprayed into the cutting chamber. This not only partially cleans the PE film, the water acts as a lubricant reducing heat and friction buildup.

3. Single-Shaft / Double-Shaft Shredder/ Crusher: Our industrial single-shaft and double-shaft shredders are designed for use in larger capacity PE film washing plants or recyclers processing PE films that have higher levels of contamination.

4. High Friction Washer: Originally designed in Germany and improved upon throughout the years, this high-power washing machine has the unique ability to thoroughly was PP / PE film scrubbing off dirt, debris, and even breaks apart paper and cardboard into fibers. Learn more about our high friction washer.

5. float / Sink Separation Tank: An essential part of the PE film washing line, the separation tank is the major line of defence against contaminants. Using water as a medium, PP / PE film that float are separated from contaminants that sink such as sand, rocks, glass, metals, and other plastics such as PET, PA, PS, etc.

6. Dewatering Machine: The first stage in the drying process, the dewatering machine uses centrifugal foce to remove a large portion of water content from PP/PE film coming directly from the washers.

7. Dewatering Screw Press: A different type of dewatering machine, the screw press uses pressure to squeeze water from the PP/PE film coming directly from the washers. It’s up to you to decide which dewatering machine is more suitable for your needs.

8. Thermal Drying System: The PP/PE film is vacuumed out of the dewatering process and dehydrated through a series of stainless steel tubes. Our effection drying system can reduce moisture content to under 3%. This is the final preparation process for the PP/PE film before it is stored or pelletized into plastic granules.

9. Product Silo: A storage tank for the clean, dry pieces of PP or PE film.

Parts contacting with materials in PE PP washing line floating washer is made of stainless steel, stainless and no pollution to the washed materials. Full automatic design needs no adjustment during operation.

It can be making into different length according to different requirement. This device is separate by proportion. It can adjust based on different material, reach to the aim of washing and separate.

| nput capacity | 500kg/h | 1000 kg/h | 2000 kg/h |

| Workshop(M*M*M) | 42 (L)×10(W)×6(H) | 55(L)×15(W)×6(H) | 70(L)×18(W)×6(H) |

| Ancillary staff | 6Persons | 8 Persons | 12 Persons |

| Installation power | 156KW | 307KW | 420KW |

| Water Consumption: | 2Ton/h | 3.5Ton/h | 5 Ton/h |

| Final product | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max.20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: max. 20oom Floatable contamination: less than 200ppm Total impurity: 320ppm | Moisture: max 1% Bulk density: 0.3G/CM3 Particle size: 14-18mm Metal content: Max. 20ppm Floatable contamination: less than 200ppm Total impurity: 320ppm |

Why Choose hopesun

* Over 20 years experiences focus on recycling machine. The biggest plastic recycling machine factory in south China. We have the strength give better service and price to you.

* Overseas Service Station: We have service station, cooperate reseller more than 40 countries. hopesun can meet your requirements on testing, installation and after sales service.

* OEM/ODM is Supported: We have a strong R&G team. We can research and development suitable color sorter for you.

* Quality Process Assurance: We pass ISO quality management system, each process of production are under strictly standard.

* Shipping Guarantee: we have professional packaging operations team, independent export qualification to ensure product safety and stability to reach customers in the hands.

* After-sales Service Guarantee: We provide one year warranty and lifetime maintenance. Free home repair during the warranty period (except for human factors or irresistible natural phenomena caused by failure or damage)

* Sales team: Our professional sales team is fluent in English, Russian, Chinese , Spanish and Japanese. Can communicate better with customers.