Shandong Honest Machinery Co., Ltd. |

|

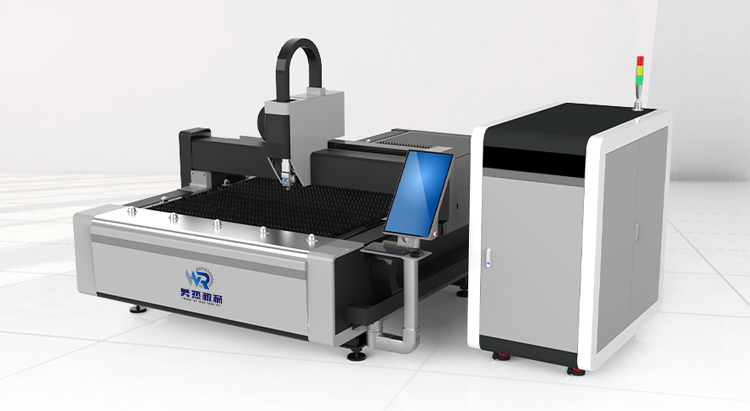

3015 High Speed Aluminum Steel Industrial Metal Fiber Laser Cutting Machine

►Machine overview

Fiber laser cutting, because the invisible beam replaces the traditional mechanical knife, the mechanical part of the laser head has no contact with the work, and will not cause scratches on the work surface during work; the laser cutting speed is fast, the cutting is smooth and flat, generally not Need follow-up processing; cutting heat affected zone is small.

►Machine Data

| Crossbeam | Steel Beam |

| Laser | MAX 1000W |

| Cutting head | RayTools |

| Control System | Cypcut |

| Guide | HIWIN |

| Rack | YYC |

| Reducer | SIMPO |

| X axis servo motor | YASKAWA |

| Y axis servo motor | YASKAWA |

| Z axis servo motor | YASKAWA |

| Chiller | S&A |

| Electrical control | CHINT |

| Proportional valve | SMC+CKD |

| Computer | Industrial PC |

| Sheet metal appearance | Independent research and development |

| Other standard configuration | Protective glass |

| Focusing lens | |

| Collimator | |

| Copper mouth, protective lens | |

| Toolbox | |

| Protective glasses |

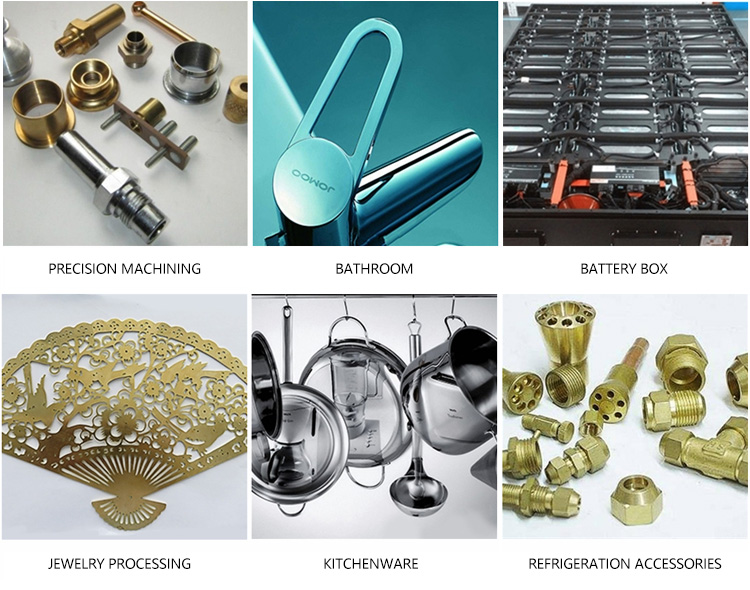

►Application

1. Sheet metal processing:Fiber laser cutting machine has the advantages of high precision, high speed, flexible processing (without mold opening), etc., and it has become a product of sheet metal processing. The high quality and high speed of fiber laser cutting machine are unique in the sheet metal industry and are favored by sheet metal companies.

2. Automobile manufacturing:The automobile industry is a technology-intensive industry. Fiber laser cutting machine laser is a kind of cutting equipment. Now 50%~70% of auto parts are processed by laser. The automobile industry mainly uses laser welding and laser cutting as the main processing. Means, including plane cutting, three-dimensional cutting.

3. Chassis cabinet:Manufacturers of computer cases, electrical switches, electrical cabinets, and elevators choose Pentium Laser's fiber laser cutting machine. What they value is the stability and high speed of the equipment. There is no need for secondary processing of the workpiece, which greatly increases production efficiency and reduces production costs.

4. Advertising industry:The advertising industry is now more and more processing and cutting metal characters. Traditional metal characters have to go through a variety of processing techniques such as bending, welding, and polishing. Now, as long as the graphics are input into the computer, the fiber laser cutting machine can be used. Perform high-speed cutting.

►Product Advantage

Fiber lasers have several main advantages: The light propagating in the fiber can shield environmental interference well. The design of fiber lasers is often very compact. They have a large gain bandwidth, a wide wavelength tuning range, and the ability to generate ultra-short pulses. . They operate with high power and efficiency and are suitable for many types of cutting procedures.

Fiber lasers can cut through thin materials at high speeds. They also have the ability to cut reflective materials. They can cut high anti-metals such as copper, brass, and aluminum without damaging the machine.

No thermal damage to objects:

The laser from a fiber laser cutting machine is very powerful,

which is why it can easily cut thick materials such as steel. And

their accuracy is so high that the beam will not cause any damage

to surrounding materials. Many industries can benefit from this.

For example, in the electronics industry, light beams need to work

in a very small size without damaging any components necessary for

these electronic devices to work properly.

Outstanding performance:

Fiber lasers have higher performance than many similar products.

Fiber lasers provide a higher level of beam quality, can be highly

focused to achieve a very high level of accuracy, and increase

power density. This also means that tasks can be completed at a

faster speed and lower power consumption.

The main reason for using fiber laser cutting technology is to reduce the mechanical stress on the sheet metal parts during cutting. Laser helps to eliminate impact stress that may adversely affect sheet metal products during the cutting process. In addition, the heat-affected zone is very small, and the rest of the workpiece is hardly exposed to heat, thus retaining the characteristics of the processed material.

In addition, because laser cutting does not have a negative impact on the sheet metal, it helps to minimize waste-intensive cutting can make more parts per square meter of sheet metal.