Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

High precision PLF060-L1-(3,4,5,7,10)-S2-P2 series planetary gearboxs are widely used in industrial automation fields and warmly appreciated by our customers.

Planetary gearboxes machines are widely used in the industrial fields, especially suitable for applications that require high precision, high load and high reliability, such as CNC machine tools, civil carving machines, medical equipment, laser equipment, automobile manufacturing, robotics, metallurgy Rolling machines and roll machines, aerospace, military equipment, new energy system, communication automatic adjustable antennas, scientific measurement of calibration equipment, shipbuilding industry, etc.

The following are several common APPLICATIONS of planetary reducer in the industrial field:

Planetary gearboxes machines are widely used in the industrial fields, especially suitable for applications that require high precision, high load and high reliability, such as CNC machine tools, civil carving machines, medical equipment, laser equipment, automobile manufacturing, robotics, metallurgy Rolling machines and roll machines, aerospace, military equipment, new energy system, communication automatic adjustable antennas, scientific measurement of calibration equipment, shipbuilding industry, etc.

Machinery manufacturing: Planetary reducer can be used to drive various rotor components on the machine tools, such as lathes, milling machines, grinding machines, etc.

Packaging machinery: Planetary reducer can be used to drive various packaging equipment such as sealing machines, filling machines, labeling machines, and marking machines to achieve efficient and accurate packaging movements.

Textile machinery: Planetary reducer can be used for transmission of textile production equipment such as weaving machines, rolling machines, printing and dyeing machines to improve production efficiency and product quality.

Printing machinery: Planetary reducer can be used for transmission of printing equipment such as plastic printers, flat printing machines, soft printers, etc., to achieve precise and fast printing processes.

The field of aerospace: Planetary reducer can be used as high precision, high performance, high reliability forces, which are widely used in aircraft, missiles, satellites, aerospace fields.

Automotive industry: Planetary reducer can be used in the transmission of gearboxes, engines, hub reducers, power transmission, clutch and other components of the automotive industry to improve the power and fuel economy of automobiles.

The field of petrochemical industry: Planetary reducer can be applied to petroleum, chemical industry and other fields. In the process of natural gas, chemical production, it is used as a driver equipment.

Medical equipment: Planetary reducer can be used for transmission of medical equipment such as X -ray machines, CT machines, and nuclear magnetic resonance to ensure the stability and accuracy of medical equipment.

Metallurgical machinery: Planetary reducer can be used for the transmission of metallurgical production equipment such as rolling machines and casting machines to improve production efficiency and product quality.

Various industrial robots: Planetary reducer can be used for the transmission and execution agencies of various industrial robots to improve the accuracy and execution efficiency of robots.

The working principle of planetary reducer is based on the basic principles of the planetary rotation system. It consists of multiple planet wheels, inner gear, solar wheels, and frameworks. The number of planet wheels can be selected according to the demand for deceleration and the efficiency of transmission, usually 3 to 8. The inner gear is fixed in the frame, while the solar wheel is a central wheel, which is connected to the input shaft. When the input shaft is rotated, the solar wheels drive the planet to rotate. While the planet wheel revolves along the orbit of the inner gear, it also rotates along its own axis. This special way of exercise enables the planetary wheel system to achieve a large deceleration ratio, and also ensures the stability and accuracy of the transmission.

The rotation of the input shaft is passed to the planet wheel through the solar wheel, and the planet wheel starts to rotate under the drive of the solar wheel.

While the planetary wheel revolves along the track of the inner gear, it also rotates along its own axis. This special way of exercise enables the deceleration ratio of the planetary wheel system.

The revolver and rotation of the planet wheel pass the power to the planetary rack, and the planetary shelf transmits the power to the output shaft, which drives the entire decelerator to rotate.

Under the precision manufacturing and installation of the decelerator, the stability and accuracy of the transmission are guaranteed, enabling the planetary reducer to achieve a high -precision deceleration effect.

Kaifull PRMCAS planetary gearbox feature and advantages

High precision. The planetary reducer uses the planetary gears for power transmission. The number of gears is large and the transmission ratio is large. Therefore, its transmission accuracy is very high and the error is very small. This high precision characteristics have made planetary gearboxes widely applied in many fields. Normally helical gear planetary reducers have higher precision, i.e. lower backlash. And for same type gear reducers, also have higher precision reducers, if they are produced according to different CNC machine precision. Also need to pay attention to that fact that how long this precision can be kept. Kaifull PRMCAS planetary gearboxes can work with precision with average time of 20000hours.

In the market there are some planetary reducers which can work with stepper motors, but without precision, which is not recommended.

Strong loading capacity. The structure of the planetary gearbox is very compact and the gears are evenly distributed, so its loading capacity is very strong and can withstand a large load. Different producer planetary gearboxes loading capacities are normally different, which is related with not only design, but also the materials used.

High transmission efficiency. The transmission efficiency of the planetary reducer is very high, and its efficiency can reach up to 98%! This high-efficiency feature has made planetary reducer widely applied in some applications with high energy consumption requirements. Higher transmission efficiency makes the heating, noises much lower, also help customers to save wasted power and increase processing quality of workpiece.

Long lifetime. The gears of the planetary reducer are made of high strength, high hardness materials. It is precise processing and thermal treatment, so it has a relatively long service life. In addition, the structure of the planetary reducer is compact and the internal components wear less. It is also one of the reasons for its long life. Also need to consider the life time with precision, not just not able to work without precision life time.

These characteristics have made planetary reducers widely applied in many industrial automation areas, and become an indispensable important device in the fields of modern machinery processing and automation production.

Naming Rules

| Matched Motors | Servos motor: 100W, 200W, 400W | ||||

| Reduction Ratios | 3:1 | 4:1 | 5:1 | 7:1 | 10:1 |

| Backlash (arcmin) | <8arcmin | ||||

| Rated Input Speed (rpm) | 3000 | ||||

| Max. Input Speed (rpm) | 6000 | ||||

| Rated Outout Torque (N.m) | 16.5 | 27 | 27 | 19.5 | 8.5 |

| Max. Output Torque (N.m) | 33 | 54 | 54 | 39 | 17 |

| Rotor Inertia (Kgcm2) | 0.107 | 0.094 | 0.092 | 0.091 | 0.091 |

| Max. Radical Force (N.m) | 170 | ||||

| Max. Axial Force (N.m) | 120 | ||||

| Average Lifetime (hours) | >20000 | ||||

| Noise Level (dB) | 60 | ||||

| IP Grade | IP65 | ||||

| Lubrication | Long-term Grease | ||||

| Efficiency | 97% | ||||

| Weight (Kg) | 1.2 | ||||

| Shaft Adaptor | Available | ||||

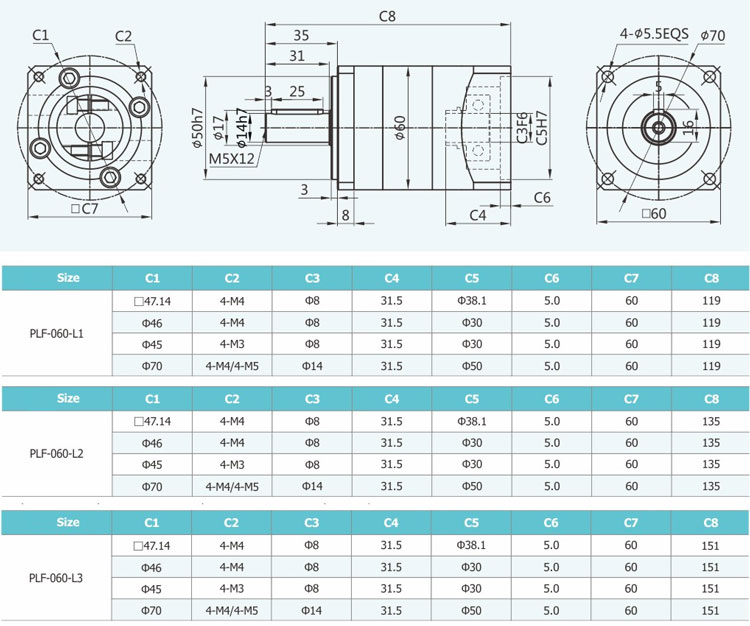

3. Mechanical Drawings (in mm) & Wirings

Note: If you find difficulty in model selection, just kindly contact us and the most proper reducer will be recommended.

More Types of Spur Gear Planetary Gearboxes Available

High Standard Quality Management System