Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

Kaifull PRMCA planetary gear reducers applications reference.

Machinery manufacturing: Planetary reducer can be used to drive various rotor components on the machine tools, such as lathes, milling machines, grinding machines, etc.

Packaging machinery: Planetary reducer can be used to drive various packaging equipment such as sealing machines, filling machines, labeling machines, and marking machines to achieve efficient and accurate packaging movements.

Textile machinery: Planetary reducer can be used for transmission of textile production equipment such as weaving machines, rolling machines, printing and dyeing machines to improve production efficiency and product quality.

Printing machinery: Planetary reducer can be used for transmission of printing equipment such as plastic printers, flat printing machines, soft printers, etc., to achieve precise and fast printing processes.

The field of aerospace: Planetary reducer can be used as high precision, high performance, high reliability forces, which are widely used in aircraft, missiles, satellites, aerospace fields.

Automotive industry: Planetary reducer can be used in the transmission of gearboxes, engines, hub reducers, power transmission, clutch and other components of the automotive industry to improve the power and fuel economy of automobiles.

The field of petrochemical industry: Planetary reducer can be applied to petroleum, chemical industry and other fields. In the process of natural gas, chemical production, it is used as a driver equipment.

Medical equipment: Planetary reducer can be used for transmission of medical equipment such as X -ray machines, CT machines, and nuclear magnetic resonance to ensure the stability and accuracy of medical equipment.

Metallurgical machinery: Planetary reducer can be used for the transmission of metallurgical production equipment such as rolling machines and casting machines to improve production efficiency and product quality.

Various industrial robots: Planetary reducer can be used for the transmission and execution agencies of various industrial robots to improve the accuracy and execution efficiency of robots.

Planetary Reducer is a widely used industrial product that can reduce the speed of the motor and increase the output torque.

Planet reducer is usually closely combined with an inner tooth ring on the teeth box housing. The center of the teeth box has a solar gear driven by an external power, and the three planetary wheels are coincided with the solar wheel. When the planetary decelerator is an external input power driving the solar teeth, it can drive the planetary gear rotation, the output power of the force axis, and reduce the output speed.

In addition to the basic principles of the planetary wheel system, the performance of the planetary deceleration is also affected by many other factors. For example, the selection of materials, the application of thermal treatment process, the processing accuracy of the gear, the design of the assembly, and the design of the lubrication system will affect the performance of the reducer. Therefore, in order to obtain high efficiency, high stability, and long lifetime, strict quality control needs to be implemented in product design, manufacturing and testing etc.

Kaifull Planetary Reducers Features and advantages

High drive efficiency: The transmission efficiency of planetary reducer is usually high, and can reach more than 90%. This is because in the planetary gear transmission, multiple gears pass the power at the same time, reducing the transmission loss.

Large torque output: Planetary reducer can achieve larger torque output through multi-stage gear transmission. Each planet wheel can withstand part of the load, so that the overall load is scattered to multiple gears, increasing the torque output capacity.

Compact structure: The planetary reducer has a compact structural design. The gear device is located in a closed outer gear and occupies relatively small space. This makes the planetary gearbox special advantageous in limited space applications.

High rigidity and accuracy: Planetary reducer has high rigidity and accuracy, which can provide accurate output movement and position control. This makes the planetary reducer very important in applications that require precision exercise and positioning, such as industrial machinery and automation equipment.

Stable output movement: Due to the coordination of multiple gears, the planetary reducer provides smooth output motion, which reduces the production of vibration and noise. This is very important for applications that require low noise and stable operation.

Rich specifications and options: Planetary reducer has a variety of configurations and options, such as different deceleration ratios, input and output shaft layout, attachment and sensor installation to meet the requirements of specific applications.

Naming Rules

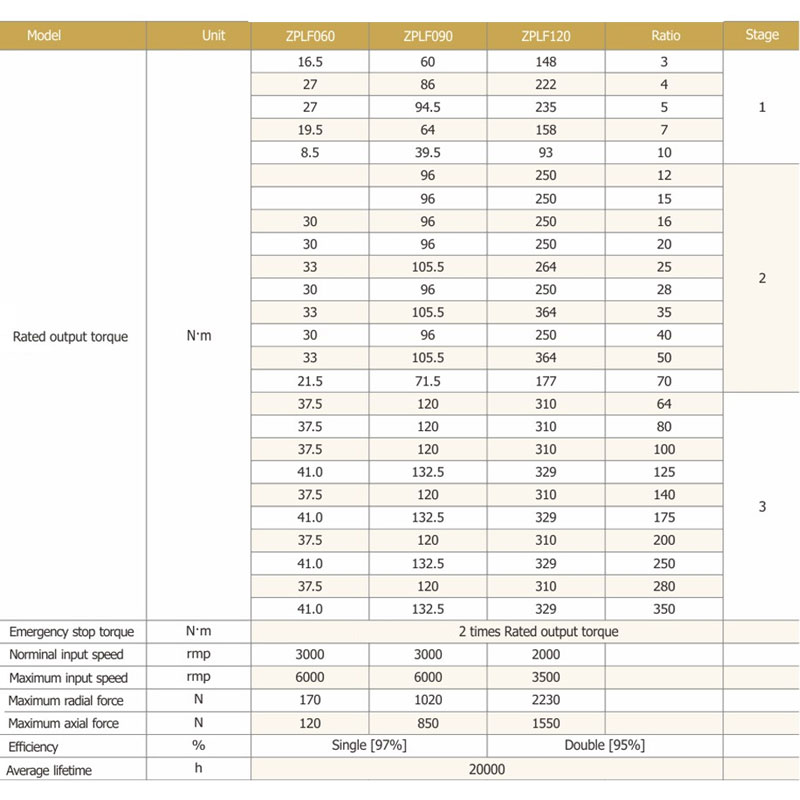

| Matched Motors | Servo motor 750W, 1000W, 1.5KW, Stepper Nema 42 & 52, frame size 110mm & 130mm | |||||||||

| Reduction 0Ratios | 64:1 | 80:1 | 100:1 | 125:1 | 140:1 | 175:1 | 200:1 | 250:1 | 280:1 | 350:1 |

| Backlash (arcmin) | <15arcmin | |||||||||

| Rated Input Speed (rpm) | 3000 | |||||||||

| Max. Input Speed (rpm) | 6000 | |||||||||

| Rated Outout Torque (N.m) | 310 | 310 | 310 | 329 | 310 | 329 | 310 | 329 | 310 | 329 |

| Max. Output Torque (N.m) | 620 | 620 | 620 | 658 | 620 | 658 | 620 | 658 | 620 | 658 |

| Rotor Inertia (Kgcm2) | 1.15 | 1.15 | 1.15 | 1.15 | 1.13 | 1.13 | 1.11 | 1.11 | 1.11 | 1.11 |

| Max. Radical Force (N.m) | 2230 | |||||||||

| Max. Axial Force (N.m) | 1550 | |||||||||

| Average Lifetime (hours) | >20000 | |||||||||

| Noise Level (dB) | 65 | |||||||||

| IP Grade | IP65 | |||||||||

| Lubrication | Long-term Grease | |||||||||

| Efficiency | 95% | |||||||||

| Weight (Kg) | 19.1 | |||||||||

| Shaft Adaptor | Available | |||||||||

Note: If you find difficulty in model selection, just kindly contact us and the most proper reducer will be recommended.

Kaifull Automation, is one of the leading middle and high-end motion control products&System vendors in China with strong R&D capabilities and rich indutrial application experiences of more than 20 years.

Such as Steppers (stepper drivers, open and closed loop motors, geared stepper motors, motors with brake, integrated drivers and motors), Linear Steppers (drivers and motors), Servos (drivers and motors, other brands), Brushless(Drivers and motors, other brands), Linear Motors (Drivers and motors), Variable Frequency Drives/Inverters(other brands), Electric Spindles(Other brands), Planetary and Harmonic Reducers, Motion Controllers(other brands), etc.

Company

|

Products & Solutions

|

Production |

|

|

|

Expertise

|

Services

|

Market |

|

|

|

5. TechnicaL Support and Services

Standard products delivery within 10-15days.

Professional and high quality customization available.

7*24 technical services via email, Teamviewer, social medias, customer visiting etc.

Site support or training for dealers both in China and customer countries.

18months or 24months warrenty for most products, epcial products will be exceptional, such as spindle motopr bearings for 6months.

Sending pareparts for repairing or repair in China and send back to customers in new shipments.

Mostly FOB, DAP or as per customer need and payment by T/T through bank accounts prefered.

Support all shipment methods, such as express, air, sea, or Sino-euro train shipment etc.