Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

ZAL120 Series Right Angle Helical Gear High Torque Low Noise Precision Planetary Gearbox for CNC Industrial Automarion

1. Products Overview

Kaifull PRMCAS extra high precision ZAL120 SERIES right-angle helical gear planetary gearboxs are widely used in high-end industrial automation fields, such as,

KAIFULL PRMCAS Helical Gear Planetary Gearbox/Reducer FEATURES are mainly as bellow,

Helical gear design: The gear surface of the planetary gear and solar gears of the planetary reducer is oblique angle, not a straight gear design. This oblique teeth design makes the mesh of gears smoother, reduces the noise and vibration of the gear, and improves the stability and accuracy of the transmission.

High drive efficiency: Due to the use of oblique teeth design, the oblique teeth reducer reduce the area of the gear surface contact area and reduce the loss of friction. Therefore, the oblique planet reducer has high transmission efficiency and can more effectively pass the input torque to the output end.

High -torque density: Planet reducer transmission through multi -stage planet wheels, so that the input torque can be scattered to multiple planet wheels. This design improves the torque density of the reducer and enables it to provide large output torque at a smaller volume and size.

The compact structure: The oblique teeth design of the planetary gear and solar gear of the planetary reducer makes the overall structure of the reducer more compact. Compared with other types of reducers, diagonal gear planet reducer can provide higher output torque and transmission ratios in the same size.

High rigidity and stability: The planetary gears and solar gears of the planet reducer are rigid structures, which can provide high rigidity and stability. This makes the reducer show better performance under high load and high -speed exercise, and can maintain accurate transmission ratio and stability of movement.

Reliability and durability: The oblique planet reducer uses high -intensity materials and precision manufacturing processes, which has high reliability and durability. It can maintain stable performance in long -term operation and have a long life.

In summary, the slashing gear planet deceleration machine has the characteristics of oblique teeth design, high transmission efficiency, high torque density, compact structure, high rigidity and stability. These characteristics have widely used the oblique planet reducer to be widely used in the precision industry, which improves equipment accuracy and workpiece quality.

2. Technical Specifications

ZAL120 Series Helical Gear Planetary Gearbox General Technical Specifications

| Rated Input Speeds(RPM) | 3000 | ||||

| Max. Input Speed (RPM) | 6000 | ||||

| Max. Radical Force (N) | 2400 | ||||

| Max. Axial Force (N) | 2200 | ||||

| Efficiency | 97% for 1-stage or 95% for 2-stage | ||||

| Noise (dB) | 62 | ||||

| Average Lifetime (hour) | 20000 | ||||

ZAL120 Series 1-stage models main technical data

| Structure | 1-stage | ||||

| Reduction Ratios | 3:1 | 4:1 | 5:1 | 7:1 | 10:1 |

| Rated Output Torque (N) | 120 | 180 | 180 | 180 | 120 |

| Emergency Stop Torque (N) | 360 | 540 | 540 | 540 | 360 |

| Rotor Inertia (Kgcm2) | 3.25 | 2.74 | 02.71 | 2.62 | 2.57 |

| Blacklash (arcmin) | 2 types: <3arcmin for P0 precision | ||||

ZAL120 Series 2-stage models main technical data

| Structure | 2-stage | ||||||||||

| Reduction Ratios | 15 | 16 | 20 | 25 | 28 | 30 | 35 | 40 | 50 | 70 | 100 |

| Rated Output Torque (N) | 180 | 230 | 230 | 255 | 230 | 180 | 255 | 230 | 255 | 180 | 120 |

| Emergency Stop Torque (N) | 540 | 690 | 690 | 765 | 690 | 540 | 765 | 690 | 765 | 540 | 360 |

| Rotor Inertial (kg.cm2) | 2.56 | 1.75 | 01.5 | 1.49 | 1.3 | 1.3 | 1.3 | 1.3 | 1.5 | 1.5 | 1.5 |

| Blacklash (arcmin) | 2 types: <5arcmin for P0 precision | ||||||||||

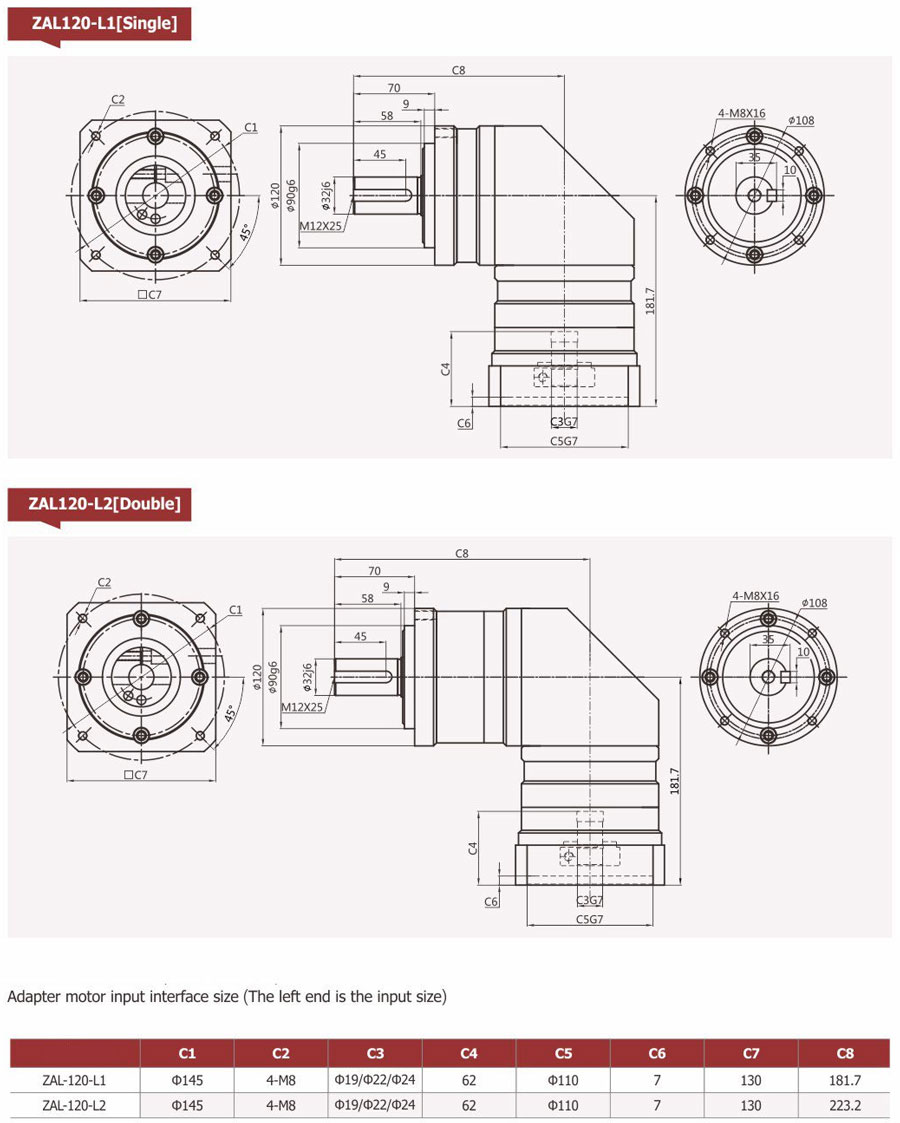

3. Mechnical Drawings (In mm)

Note: If you find difficulty in model selection, just kindly contact us and the most proper reducer will be recommended or customized.