Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

1. Product Overview

Step motor is a motor that converts the digital pulse signal into a rotation angle. Its movement is discrete and is carried out in the unit of step length. Therefore, it has high positioning accuracy and repetitive accuracy. The step motor consists of a rotor, a stator, or an encoder for closed-loop stepper motor. The role of the encoder is to detect the rotation position and help control the motor.

When driving the motor, the controller convert the target movement into pulses and then send these pulse signals to a stepper motor driver. The stepper motor driver identify the signals and cover these signals into motor driving pulses. These pulse signals are associated with the angle of the motor rotation. By switching the switch of the coils, the precise rotation of the step motor can be achieved in turn. The control signal can accurately control the rotation of the motor to achieve positioning and control.

The stepper motor has the characteristics of accurate position control, high positioning accuracy, reliable work, and small noise. It is often used in the fields of precision instruments, robots, electronic equipment. Its unique working principle enables the stepper motor to accurately operate without feedback signal, which improves the efficiency and accuracy in applications and reduces production costs.

Kaifull two-phase, three-phase, and five-phase hybrid step motors are made of high-temperature permanent magnet and high-quality cold-rolled steel sheets. Our stepper motors range is very rich, covering 20mm to 150mm in frame size. At the same time, there are all-in-one step motors that integrated with drivers, closed-loop stepper motor, and with brake stepper motor etc..

Generally speaking, the Kaifull hybrid stepper motors' characteristicsare:

Easy drive.

No matter how the input current changes, as long as the load can be driven, the step motor moves according to the minimum angle.

No feedback signal is required. The step motor moves according to the pulse frequency and quantity given by the drive, and does not need to rely on the motor actual status feedback.

The positioning error does not accumulate. The reason why the stepping motor does not accumulates is because it does not need to know the actual location, but only needs to know the number of rotating steps. Therefore, the step motor only needs to receive the signal of each step, and then move according to the step angle. It is not necessary to know the starting location or target location. This can avoid the problem of accumulating errors. In addition, the working principle of the stepper motor makes the movement discrete and performed from a specific angle without a continuous accumulation error.

Stepper motor driver principle is simple and easy to develop control system.

Step motor has the characteristics of high power density, high output torque, low noise, low vibration and smooth rotation, high energy conversion efficiency, stable and reliable, long life etc. At the same time, our company supports the flexible customization, too.

The Applications of Kaifull PRMCAS Hybrid Stepper Motors

Kaifull hybrid stepper motors are mainly used in digital control systems, with high accuracy and reliable operation. If position detection and speed feedback are used, closed-loop control can also be achieved. Stepper motors have been widely used in digital control systems, such as digital to analog conversion devices, CNC machine tools, computer peripherals, automatic recorders, clocks, etc. In addition, they have also been applied in industrial automation production lines, printing equipment, etc.

The application scenarios of Kaifull stepper motors are very wide, and the following are some application examples:

Industrial field: Stepper motors are used in automotive instrumentation, machine tool automation production equipment, robot manufacturing, inspection, and process flow.

Security field: Used for monitoring products, such as PAN/ZOOM/TILT for security cameras.

Medical field; Hydraulic pumps, ventilators, and blood analyzers used in medical scanners, samplers, digital oral photography.

In the field of consumer electronics, it is used in various stages of electronic product production, such as solder paste printing, SMT placement, reflow soldering, visual inspection, production of cables with terminals, dispensing machines, screen laminating machines, 3D printers, etc.

Precision equipment and instruments: used in ATM machines, inkjet printers, engraving machines, photo machines, spray painting equipment, computer peripherals and massive data storage devices, precision instruments, industrial control information systems, office automation, robots and other fields, especially suitable for applications with smooth operation, low noise, fast response, long service life, and high output torque.

Textile machinery: It is widely used in textile machinery equipment such as computerized embroidery machines. These stepper motors have the characteristics of low torque retention, fast response speed, low operating noise, stable operation, good control performance, and low overall cost.

Flat mobile devices: such as laser cutting machines, printers, scanners, etc.

Measurement instruments: such as high-precision 3D scanners, optical measurement equipment, etc.

Medical equipment: used for medical and surgical instruments, etc.

Camera lens. Used for focusing and moving optical devices, etc.

These application scenarios typically require stepper motors to have characteristics such as high precision, low noise, fast response, and long lifespan to meet the positioning, control, and performance requirements of different industries.

2. Hybrid Stepper Motor General Technical Specifications

| Step Angle | 1.8° (2 Phase) |

| Step Angle Accuracy | 0.09° |

| Shaft Type | Single, Dia. 4mm (Customizable) |

| Max. Temperature Rise | Less than 80 °C (Rated Current) |

| Max. Surface Temperatures | Max Allowed 100℃ |

| Ambient Temperature | -20 °C ~ +50 °C |

| Insulation Grade | 100 MΩ Min. , Class B |

| Dielectric Strengt | 500 VAC for 1 Minute |

| Max. Axial Load | 5N |

| Max. Radial Load | 25N (10mm from mounting Surface) |

| Certificates | Rohs, CE, CCC (As per Customer Need) |

3. Hybrid Stepper motor Performance Datasheet

| Model | Current | Resistance | Inductance | Holding Torque | Detent Torque | Rotor Inertia | Bi/Unipolar | Weight | Length |

| A/Ø | Ω/Ø | mH/Ø | N.cm | N.cm | g.cm2 | # of Leads | g | mm | |

| 28HS018-1004S-50-4.5F | 1.0 | 4.4 | 4.0 | 18.0 | 0.8 | 18 | Bi (4) | 200 | 50.4 |

4. Mechanical Dimensions (in mm)

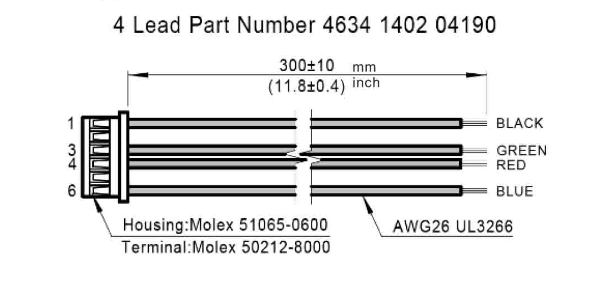

5. Matching Connector with Leads Dimenssions

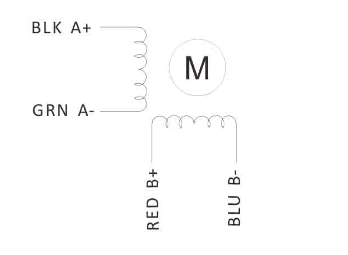

6. Wiring Diagram

7. Torque Speed Curves