Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

1. Products Overview

Step motor is a motor that converts the electrical pulse signal into the corresponding angle displacement. For each of the pulse signal, the rotor rotates a certain angle accordingly, and the speed is proportional to the input pulses’ frequency. Therefore, step motor is also called pulse motor.

The biggest difference between step motor compared to other control motors is that it receives digital control signals (pulses) and converts into angle displacement accordingly. Enter a pulse signal to get a specified position increment. Compared with the traditional DC control system, such a so-called incremental position control system, the stepper system complexity and cost are significantly reduced. The angular displacement of the stepping motor is strictly proportional to the number of input pulse, and it is synchronized with the pulse in time. Therefore, by controlling the pulse frequency and pulse quantity, the motor shaft speed, and position can be controlled precisely too.

At the same time, Kaifull has solved many problems of traditional stepper drivers buy the latest patented technologies. There are many middle and high end customers globally, and they highly appreciate our stepper motor and drives very much.

Several advantages of stepper motors

High precision

The rotation angle of the stepper motor can be finely controlled, and each step corresponds to a determined rotation angle, so the rotation accuracy of the stepper motor is very high. Compared with traditional DC and AC motors, stepper motors can more accurately control position and angle, making them suitable for applications that require high-precision position control.

Wide speed adjustment range

The speed of a stepper motor is determined by the driving current and voltage, so the stepper motor can achieve a wide range of speed adjustment. Meanwhile, according to different loads, the stepper motor can adapt to load changes by changing the driving signal, thereby maintaining a constant speed. Based on the frequency of the input pulse signal, smooth speed regulation can be achieved.

Fast response speed

The response speed of the stepper motor is very fast, and it can complete rotation instructions in milliseconds. This is determined by the special nature of the stepper motor control method. Traditional motors require acceleration and deceleration processes to achieve rotation, while stepper motors can achieve rapid rotation by controlling pulse frequency and time.

High torque

A stepper motor can generate a very large torque and maintain a high torque even at high speeds. This is due to the special driving method of the stepper motor, which can maintain a constant torque output in each stepper cycle. Therefore, stepper motors are suitable for applications that require high torque generation.

Long service life and cost savings

The production cost of stepper motors is relatively low, occupying small space, and easy to install and maintain, so their usage cost is very low. Meanwhile, due to the ability to achieve position and angle control through control signals, complex sensors and control circuits in traditional control methods can be eliminated, resulting in cost savings. At the same time, the stepper motor does not need to adjust the phase through brushes and commutators like ordinary DC motors, reducing friction. In addition, we use unique and high-quality materials, so the Kaifu hybrid stepper motor has a long lifespan and hardly requires special maintenance, further reducing customer costs.

Target Applications of Kaifull PRMCAS Hybrid Stepper Motors

Machine tools and engraving machines

The application of stepper motors in machine tools is also very common. In machine tools, stepper motors are used to control the feed and tool retraction, thereby achieving precision and speed in machining workpieces. It can achieve different processing effects, high speed, and high efficiency.

Automation equipment

The application of stepper motors in automation equipment is also very extensive. In automation equipment, stepper motors are used to control the position and speed of various moving components, thereby achieving automation control of the equipment. It can achieve different control effects, such as high speed and high stability.

Printing machines

Stepper motors are widely used in printers. In a printer, a stepper motor is used to control the movement of the print head, thereby achieving precise printing of text, images, and charts. It can achieve different printing effects, such as high definition, high speed, and high stability.

Automotive components

The application of stepper motors in automotive components is also very common. In automotive components, stepper motors are used to control the position and speed of car seats, rearview mirrors, windows, and doors, thereby achieving automated control of automotive components. It can achieve different control effects, such as high speed and high reliability.

Optical equipment

In optical equipment, stepper motors are widely used in modulators, fine-tuning, and other aspects. Because the action of stepper motors is very slow and the stepper angle can be adjusted, they are widely used in various optical positioning mechanisms, which can provide higher stability and accuracy for optical equipment.

Medical devices

Stepper motors are widely used in medical devices, especially in surgical instruments such as blades and cutters. The high-precision positioning of stepper motors can significantly improve the accuracy of surgery and make surgery safer. Stepper motors can also be used in devices such as pacemakers and syringes.

Precision positioning applications

Stepper motors can complete precise positioning tasks through quantitative motion and fixed step angles, which makes them widely used in various precision positioning equipment, such as optical equipment, textile equipment, computer embroidery machines, medical equipment, automation equipment, etc. These equipment usually require high-precision and stable positioning machinery, and stepper motors are perfect for such tasks.

In summary, stepper motors can be widely used in various fields due to their characteristics of quantitative motion and fixed stepper angle, providing more precise and efficient driving force for mechanical equipment to achieve higher production efficiency and quality.

2. Hybrid Stepper Motor General Technical Specifications

| Step Angle | 1.8° (2 Phase) |

| Step Angle Accuracy | 0.09° |

| Shaft Type | Single shaft, Dia. 14.0 or 12.7mm (Customizable) |

| Max. Temperature Rise | Less than 80 °C (Rated Current) |

| Max. Surface Temperatures | Max Allowed 100℃ |

| Ambient Temperature | -20 °C ~ +50 °C |

| Insulation Grade | 100 MΩ Min. , Class B |

| Dielectric Strengt | 500 VAC for 1 Minute |

| Max. Axial Load | 60N |

| Max. Radial Load | 320N (10mm from mounting Surface) |

| Certificates | Rohs, CE, CCC (As per Customer Need) |

3. Hybrid Stepper motor Performance Datasheet

| Model | Current A/Ø | Resistance Ω/Ø | Inductance mH/Ø | Holding Torque N.m | Rotor Inertia g.cm2 | Lead # of Leads | Weight kg | Length mm | Matching Drive |

| 86AHS290-6408S-67-12.7F | 6.4 Parrallel | 0.24 | 1.7 | 2.9 | 1100 | 8 | 1.6 | 66.5 | Y2SD3 |

| 86AHS290-3208S-67-12.7F | 3.2 Serial | 0.96 | 6.8 | 2.9 | 1100 | 8 | 1.6 | 66.5 | Y2SD2 |

4. Mechanical Dimensions (in mm)

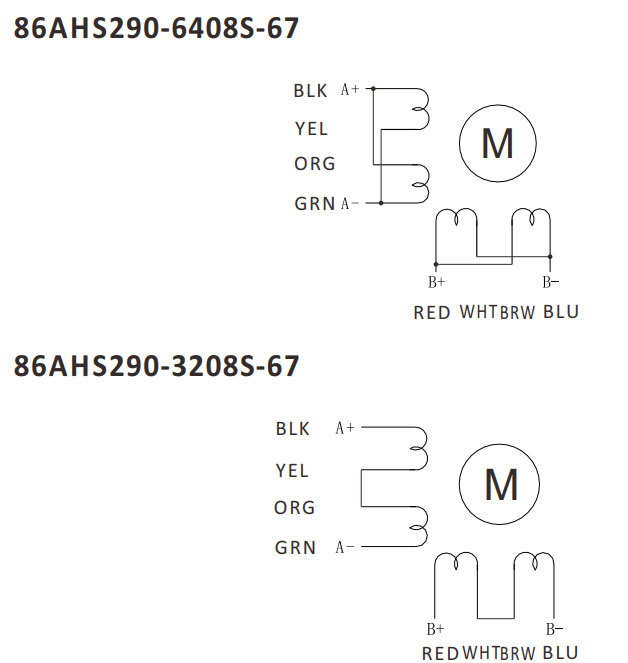

5. Wiring Diagram

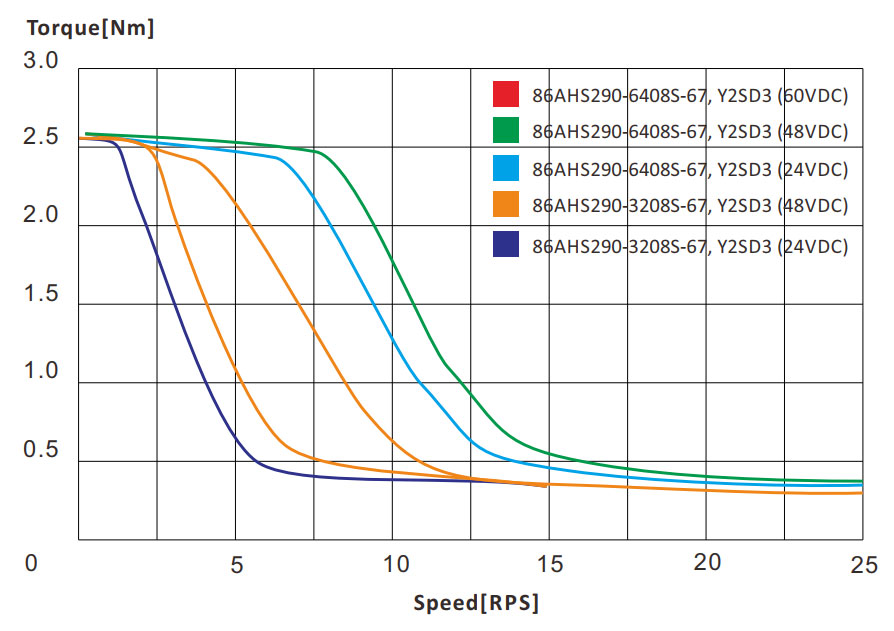

6. Torque Speed Curves