Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

1. Products Overview

Step motor is a motor that converts the electrical pulse signal into the corresponding angle displacement. For each of the pulse signal, the rotor rotates a certain angle accordingly, and the speed is proportional to the input pulses’ frequency. Therefore, step motor is also called pulse motor.

The biggest difference between step motor compared to other control motors is that it receives digital control signals (pulses) and converts into angle displacement accordingly. Enter a pulse signal to get a specified position increment. Compared with the traditional DC control system, such a so-called incremental position control system, the stepper system complexity and cost are significantly reduced. The angular displacement of the stepping motor is strictly proportional to the number of input pulse, and it is synchronized with the pulse in time. Therefore, by controlling the pulse frequency and pulse quantity, the motor shaft speed, and position can be controlled precisely too.

At the same time, Kaifull has solved many problems of traditional stepper drivers buy the latest patented technologies. There are many middle and high end customers globally, and they highly appreciate our stepper motor and drives very much.

Although the stepper motor and its control technology are currently very mature, if not used properly, there may still be a situation of step loss, i.e. position error. Next, we will analyze the common causes and solutions of position errors.

The reasons for the position error of stepper motors

Large load inertia

When the inertia of the load driven by the stepper motor is large, its inertia will generate inertia force, causing the current waveform output by the stepper motor controller to be inconsistent with the actual required current waveform, resulting in inaccurate position of the stepper motor.

The stepper motor driver is not set correctly

Incorrect settings of the stepper motor driver, such as fine fraction, step angle, and other parameter settings, can also lead to an increase in the position error of the stepper motor.

The pulse signal output by the stepper motor controller is unstable

When the pulse signal output by the stepper motor controller is unstable, it can lead to inaccurate position of the stepper motor. This situation is more common when using long-distance transmission of control signals.

The stepper motor is damaged

The rotor or stator of the stepper motor may be damaged, or the bearings may be damaged, which can lead to positional errors in the stepper motor.

Methods to solve the position error of stepper motors

Control load inertia

The position error of the stepper motor can be reduced by reducing the load inertia. For example, when driving a stepper motor with inertia loads, methods such as installing shock absorbers and changing the load inertia mode can be used to reduce the load inertia.

Set the driver parameters correctly

Correctly set the subdivision and step angle parameters of the stepper motor driver to ensure the position accuracy.

Stable output pulse signal

High precision pulse generators or adjustable filters can be used to stabilize the output pulse signal and reduce the position error of stepper motors.

Replace damaged stepper motor components

When the stepper motor is damaged, it is necessary to replace the corresponding components in order to restore the normal operation of the stepper motor.

Target Applications of Kaifull PRMCAS Hybrid Stepper Motors

Mainly used in industries, aerospace, robotics, precision measurement and other fields, such as optoelectronic theodolites for tracking satellites, military instruments, communication and radar equipment, the widespread application of subdivision drive technology makes the phase number of motors not limited by step angle, bringing convenience to product design. At present, in the subdivision drive technology of stepper motors, chopping constant current drive, instrument pulse width modulation drive, and current vector constant amplitude uniform rotation drive control are adopted, greatly improving the operating accuracy of stepper motors and promoting the development of stepper motors in the direction of high-speed and precision in medium and low-power applications.

Kaifull hybrid stepper motors are currently widely used in various automation equipment and instruments such as engraving machines, laser machines, CNC machine tools, textile and clothing machinery, medical equipment, measuring equipment, electronic processing equipment, packaging machinery equipment, etc.

In the field of robotics

In the field of robotics, stepper motors are widely used to control the motion and direction of robot arms. By sending pulse signals on the motor, the robot can easily and accurately pick up or place items.

Printing assembly

In the printing and assembly industry, stepper motors achieve high-quality printing and assembly by controlling the movement of rollers, discs, and other moving parts on the printing machine.

Medical devices

In the field of medical devices, stepper motors are used to control the automated positioning and movement of surgical robots and medical equipment.

3D printing

In 3D printing technology, stepper motors can achieve complex 3D structures and shapes by controlling the movement of the print head.

Industrial automation

In the field of industrial automation, stepper motors are widely used in the control of various equipment, such as engraving machines, laser machines, CNC machine tools, textile and clothing machinery, medical equipment, measuring equipment, electronic processing equipment, packaging machinery and other automation equipment and instruments.

In summary, stepper motors have become an indispensable component in various application fields, helping various devices and machines complete complex actions through their stable motion and precise control.

2. Hybrid Stepper Motor General Technical Specifications

| Step Angle | 1.8° (2 Phase) |

| Step Angle Accuracy | 0.09° |

| Shaft Type | Single shaft, Dia. 14.0 or 12.7mm (Customizable) |

| Max. Temperature Rise | Less than 80 °C (Rated Current) |

| Max. Surface Temperatures | Max Allowed 100℃ |

| Ambient Temperature | -20 °C ~ +50 °C |

| Insulation Grade | 100 MΩ Min. , Class B |

| Dielectric Strengt | 500 VAC for 1 Minute |

| Max. Axial Load | 60N |

| Max. Radial Load | 320N (20mm from mounting Surface) |

| Certificates | Rohs, CE, CCC (As per Customer Need) |

3. Hybrid Stepper motor Performance Datasheet

| Model | Current | Resistance | Inductance | Holding Torque | Detent Torque | Rotor Inertia | Bi/Unipolar | Weight | Length |

| A/Ø | Ω/Ø | mH/Ø | N.m | N.cm | g.cm2 | # of Leads | kg | mm | |

| 86HS800-6004S-119-12.7K | 6.0 | 0.62 | 7 | 8 | 15 | 3700 | Bi (4) | 3.95 | 118.5 |

| 86HS800-3004S-119-12.7K | 3.0 | 2.48 | 28 | 8 | 15 | 3700 | Bi (4) | 3.95 | 118.5 |

4. Mechanical Dimensions (in mm)

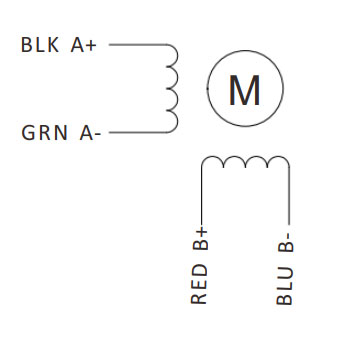

5. Wiring Diagram

6. Torque Speed Curves