Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

1. Products Overview

Step motor is a motor that converts the electrical pulse signal

into the corresponding angle displacement. For each of the pulse

signal, the rotor rotates a certain angle accordingly, and the

speed is proportional to the input pulses’ frequency. Therefore,

step motor is also called pulse motor.

The biggest difference between step motor compared to other control

motors is that it receives digital control signals (pulses) and

converts into angle displacement accordingly. Enter a pulse signal

to get a specified position increment. Compared with the

traditional DC control system, such a so-called incremental

position control system, the stepper system complexity and cost are

significantly reduced. The angular displacement of the stepping

motor is strictly proportional to the number of input pulse, and it

is synchronized with the pulse in time. Therefore, by controlling

the pulse frequency and pulse quantity, the motor shaft speed, and

position can be controlled precisely too.

At the same time, Kaifull has solved many problems of traditional

stepper drivers buy the latest patented technologies. There are

many middle and high end customers globally, and they highly

appreciate our stepper motor and drives very much.

The step motor is a motion execution agency that converts the pulse

signal into corner displacement or line displacement. Taking the

most used hybrid stepping motor as an example, its main features

are as the followings.

High loading capacity. Its speed is not affected by the load size. Unlike ordinary

motors, the speed will decrease when the load is increased. The

speed and position of the step motor have strict requirements.

Convenient control. The step motor rotates in "step", and the digital characteristics

are obvious.

Simple structure. The traditional mechanical structure for speed and position

control are more complicated, and it is difficult to adjust. After

the adoption of step motor, the structure of the whole machine is

simpler. At the same time, no need special maintenance, and the

failure ratio is very low.

100% still stop, no shaking. Because the stepper motor does not depend on feedback such as

position, speed, etc., when the input pulse stops, the step motor

can be in an absolute stop. The servo motor cannot be absolutely

stopped, so the characteristic of the stepper motor is definitely

very popular in the need for high precision applications.

Low noise. By proper subdivision setting, the step motor runs very smooth and

the noise is small, which is especially suitable for noise

sensitive applications.

Of course, there are obvious disadvantages of the stepper motor,

such as high running temperature. Although it does not affect the

service life of the stepper motor, it is not suitable for heating

sensitive applications. However, with the implement of the step

drive control algorithm, the input current adjustment range is

getting larger and larger, which helps to reduce the motor heating

significantly.

Kaifull PRMCAS Hybrid Stepper Motors Applications

Kaifull hybrid stepper motors are mainly used in digital control

systems, with high accuracy and reliable operation. If position

detection and speed feedback are used, closed-loop control can also

be achieved. Stepper motors have been widely used in digital

control systems, such as digital to analog conversion devices, CNC

machine tools, computer peripherals, automatic recorders, clocks,

etc. In addition, they have also been applied in industrial

automation production lines, printing equipment, etc.

The application scenarios of Kaifull stepper motors are very wide,

and the following are some application examples:

Industrial field: Stepper motors are used in automotive instrumentation, machine

tool automation production equipment, robot manufacturing,

inspection, and process flow.

Security field: Used for monitoring products, such as PAN/ZOOM/TILT

for security cameras.

Medical field; Hydraulic pumps, ventilators, and blood analyzers

used in medical scanners, samplers, digital oral photography.

In the field of consumer electronics, it is used in various stages of electronic product production,

such as solder paste printing, SMT placement, reflow soldering,

visual inspection, production of cables with terminals, dispensing

machines, screen laminating machines, 3D printers, etc.

Precision equipment and instruments: used in ATM machines, inkjet printers, engraving machines, photo

machines, spray painting equipment, computer peripherals and

massive data storage devices, precision instruments, industrial

control information systems, office automation, robots and other

fields, especially suitable for applications with smooth operation,

low noise, fast response, long service life, and high output

torque.

Textile machinery: It is widely used in textile machinery equipment such as

computerized embroidery machines. These stepper motors have the

characteristics of low torque retention, fast response speed, low

operating noise, stable operation, good control performance, and

low overall cost.

Flat mobile devices: such as laser cutting machines, printers, scanners, etc.

Measurement instruments: such as high-precision 3D scanners,

optical measurement equipment, etc.

Medical equipment: used for medical and surgical instruments, etc.

Camera lens. Used for focusing and moving optical devices, etc.

These application scenarios typically require stepper motors to

have characteristics such as high precision, low noise, fast

response, and long lifespan to meet the positioning, control, and

performance requirements of different industries.

2. Hybrid Stepper Motor General Technical Specifications

| Step Angle | 1.8° (2 Phase) |

| Step Angle Accuracy | 0.09° |

| Shaft Type | Single shaft, Dia. 14.0 or 12.7mm (Customizable) |

| Max. Temperature Rise | Less than 80 °C (Rated Current) |

| Max. Surface Temperatures | Max Allowed 100℃ |

| Ambient Temperature | -20 °C ~ +50 °C |

| Insulation Grade | 100 MΩ Min. , Class B |

| Dielectric Strengt | 1500 VAC for 1 Minute |

| Max. Axial Load | 150N |

| Max. Radial Load | 490N (25mm from mounting Surface) |

| Certificates | Rohs, CE, CCC (As per Customer Need) |

3. Hybrid Stepper motor Performance Datasheet

| Model | Current | Resistance | Inductance | Holding Torque | Cable Type | Rotor Inertia | Bi/Unipolar | Weight | Length |

| A/Ø | Ω/Ø | mH/Ø | N.m | g.cm2 | # of Leads | kg | mm | ||

| 110HS1900-6504S-150-19K | 6.5 | 0.67 | 13.12 | 19.0 | Direct | 10900 | Bi (4) | 8.4 | 150 |

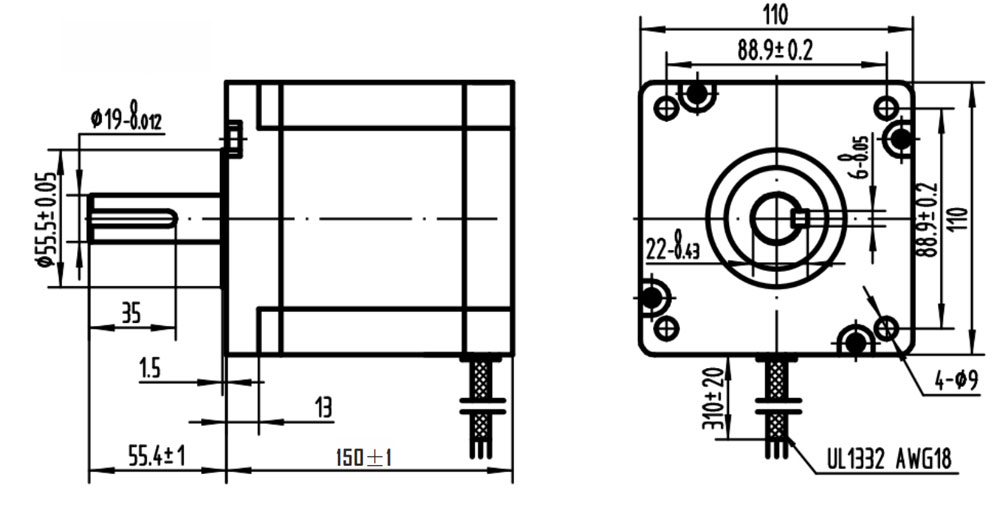

4. Mechanical Dimensions (in mm)

5. Wiring Diagram

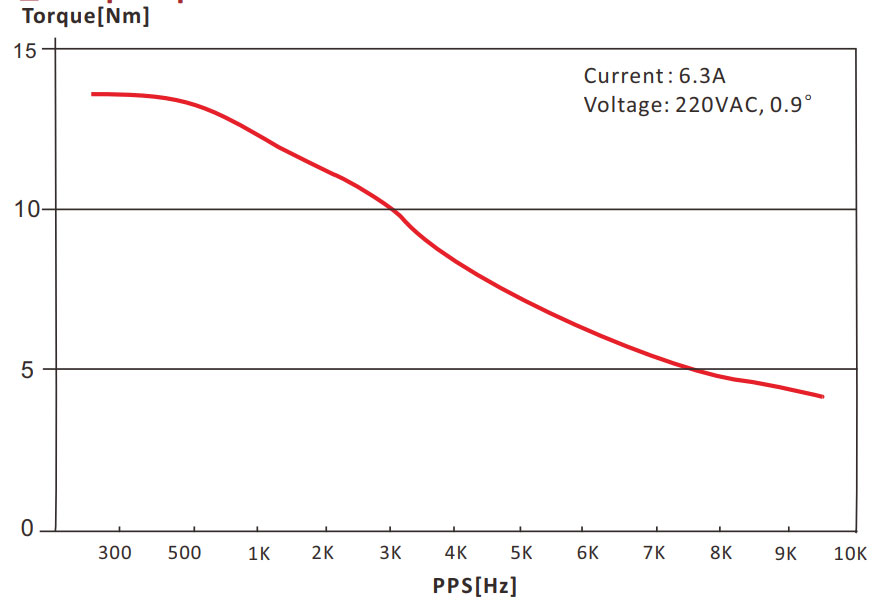

6. Torque Speed Curves