Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

1. Products Overview

Stepper motor is an executive agency that converts electrical pulses into angle displacement. You can control the angle by controlling the number of pulse to achieve the purpose of accurate position control. At the same time, you can control the speed and acceleration of the motor by controlling the input pulse frequency to achieve the purpose of the speed control.

Step motor, also called as pulse motor is normally classified by structural as: reactive step motors (VR), permanent magnet step motor (PM), and hybrid step motor (HB). Step motor can also be divided into rotation and straight lines according to the form of movement. According to whether there is an encoder, can be divided as open-loop and closed-loop step motors.

Reactive step motor: there are windings on the stator and rotor consisting of soft magnetic materials. The structure is simple, the cost is low, the step distance is small, and it can reach 1.2 °, but the dynamic performance is poor, the efficiency is low, the heating is large, and the reliability is difficult to guarantee.

Permanent Magnet step motor: The rotor of the permanent magnet step motor is made of permanent magnet material, and the rotor is the same as that of the stator. It is characterized by good dynamic performance and large output torque, but this motor has poor accuracy and large steps (generally 7.5 ° or 15 °).

Hybrid Step motor: Hybrid steaming motor integrates the advantages of reaction and permanent magnets both. It has a multi-phase windings, permanent magnet material on the rotor, and multiple small teeth on the rotor and stator to improve the step accuracy. It is characterized by large output torque, good dynamic performance, and small steps, which can meet automation applications which have high precision requirement.

According to the quantity of phases, there are two -phase, three, and five -phase step motors. The most popular is the two-phase hybrid step motor, accounting for about 97%of the market share. The reason is that the two-phase step motor is more cost-effective, and also has satisfactory performance due to subdivision or micro stepping function of its drive.

The basic step angle of a two-phase step motor is 1.8 °/step. Matched with a half-step drive, the step angle is reduced to 0.9 °. Matched with a micro stepping driver, the step angle can be subdivided up to 256 times (0.007 ° per micro step), which can meet the requirement of most applications.

Currently, stepper motors are widely used in the field of motion control. Below is a brief introduction to several issues that need to be noted when use hybrid stepper motors.

The torque of the stepper motor will decrease as the speed increases.

When the stepper motor rotates, the inductance of each phase winding of the motor will form a reverse electromotive force. The higher the speed, the greater the reverse electromotive force. In this case, the phase current of the motor decreases with the increase of frequency (or speed), resulting in a decrease in torque.

The stepper motor can work well at low speeds, but if it exceeds a certain speed, it may not start or there may be strong noise whistling.

The stepper motor has a technical parameter: no-load starting frequency, which is the pulse frequency at which the stepper motor can start normally under no-load conditions. If the pulse frequency is higher than this value, the motor cannot start normally and may experience step loss or rotor blockage. With load, the starting frequency should be lower. If the motor is to achieve high-speed rotation, there should be an acceleration process in the pulse frequency, that is to say the starting frequency should be lower, and then a certain acceleration should be applied to reach the desired high frequency (the motor speed should increase from low speed to high speed).

How to overcome the vibration and noise of two-phase hybrid stepper motors during low-speed operation?

The inherent drawbacks of stepper motors are high vibration and noise during low-speed rotation, which can generally be overcome by the following solutions:

A. If the stepper motor works exactly in the resonance zone, mechanical transmission such as changing the reduction ratio can avoid the resonance zone;

B. The most commonly used and convenient method is to use drivers with subdivision functions;

C. Replace with a stepper motor with a smaller step angle, such as a three-phase or five phase stepper motor.

Kaifull Hybrid Stapper Motors Applications

Machine tools and engraving machines

The application of stepper motors in machine tools is also very common. In machine tools, stepper motors are used to control the feed and tool retraction, thereby achieving precision and speed in machining workpieces. It can achieve different processing effects, high speed, and high efficiency.

Automation equipment

The application of stepper motors in automation equipment is also very extensive. In automation equipment, stepper motors are used to control the position and speed of various moving components, thereby achieving automation control of the equipment. It can achieve different control effects, such as high speed and high stability.

Printing machines

Stepper motors are widely used in printers. In a printer, a stepper motor is used to control the movement of the print head, thereby achieving precise printing of text, images, and charts. It can achieve different printing effects, such as high definition, high speed, and high stability.

Automotive components

The application of stepper motors in automotive components is also very common. In automotive components, stepper motors are used to control the position and speed of car seats, rearview mirrors, windows, and doors, thereby achieving automated control of automotive components. It can achieve different control effects, such as high speed and high reliability.

Optical equipment

In optical equipment, stepper motors are widely used in modulators, fine-tuning, and other aspects. Because the action of stepper motors is very slow and the stepper angle can be adjusted, they are widely used in various optical positioning mechanisms, which can provide higher stability and accuracy for optical equipment.

Medical devices

Stepper motors are widely used in medical devices, especially in surgical instruments such as blades and cutters. The high-precision positioning of stepper motors can significantly improve the accuracy of surgery and make surgery safer. Stepper motors can also be used in devices such as pacemakers and syringes.

Precision positioning applications

Stepper motors can complete precise positioning tasks through quantitative motion and fixed step angles, which makes them widely used in various precision positioning equipment, such as optical equipment, textile equipment, computer embroidery machines, medical equipment, automation equipment, etc. These equipment usually require high-precision and stable positioning machinery, and stepper motors are perfect for such tasks.

In summary, stepper motors can be widely used in various fields due to their characteristics of quantitative motion and fixed stepper angle, providing more precise and efficient driving force for mechanical equipment to achieve higher production efficiency and quality.

2. Hybrid Stepper Motor General Technical Specifications

| Step Angle | 1.2° (3 Phase) |

| Step Angle Accuracy | 0.06° |

| Shaft Type | Single shaft, Dia. 6.35 or 8.0mm (Customizable) |

| Max. Temperature Rise | Less than 80 °C (Rated Current) |

| Max. Surface Temperatures | Max Allowed 100℃ |

| Ambient Temperature | -20 °C ~ +50 °C |

| Insulation Grade | 100 MΩ Min. , Class B |

| Dielectric Strengt | 1500 VAC for 1 Minute |

| Max. Axial Load | 260N |

| Max. Radial Load | 720N (10mm from mounting Surface) |

| Certificates | Rohs, CE, CCC (As per Customer Need) |

3. Hybrid Stepper motor Performance Datasheet

| Model | Current A/Ø | Resistance Ω/Ø | Inductance mH/Ø | Holding Torque N.m | Rotor Inertia kg.cm2 | Lead # of Leads | Weight kg | Length mm | Matching Drive |

| 130AHS2800-6803S-280 | 6.8 | 0.95 | 19.0 | 28.0 | 34.0 | 3 | 17 | 220 | Y3SA3 |

4. Mechanical Dimensions (in mm)

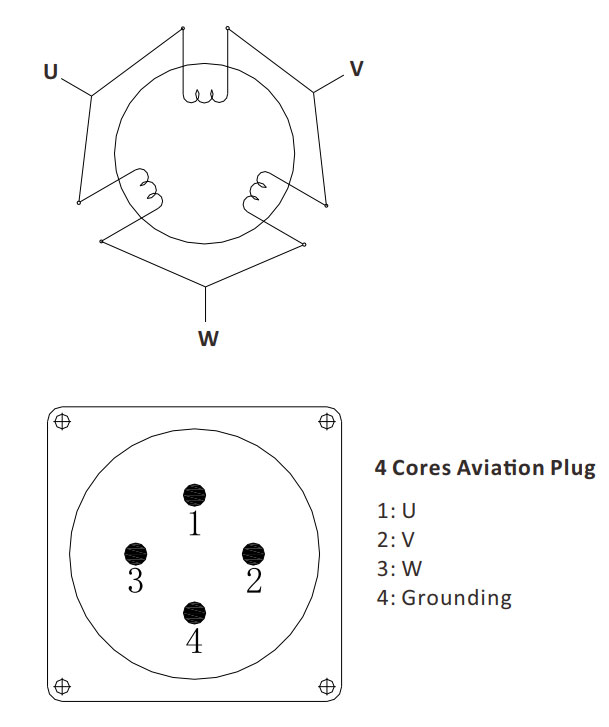

5. Wiring Diagram

6. Torque Speed Curves