QINGDAO PERMIX MACHINERY CO., LTD |

|

High Homogenization of mixing Vertical Shaft Concrete Mixer Low Noise

Protection Against Wear

The materials and coatings used to manufacture those components that come into contact with abrasive substances are specially selected for each individual application.

(1) wear - resistant alloy plates.

(2) surfacing materials.

(3) high chrome alloy.

(4) stainless steel materials.

(5) ceramic materials

(6) polyurethane material.

(7) high wear resistant rubber and cast stone materials.

Hydraulic System Maintenance Instruction

1. ISO-UNI HM46 hydraulic oil is recommended. Fill the oil to two thirds level of the indicator.

2. Before starting the hydraulic system, ensure nobody inside the machine and all he manual valves have been switched off;

3. The pressure of flood valve has been strictly adjusted to standard. Non-professional persons are forbidden to adjust the pressure;

4. Switch off the auto-control loop while using manual hydraulic system. Turn on manual stop valve and pull switching handle on the manual pump to the utmost. Then pull the handle to open the discharge door. Pull the handle in reverse to close the discharge door;

5. Strictly follow the instruction to check the condition of the pump before use if the hydraulic pump has stopped for a long time;

6. Replace the oil and oil filter after running the first 100hours, and then replace the oil or oil filter after 1000 hours running. From then on, replace oil or oil filter every 2000 hours.

7. When replace oil, clean oil tank and working components with new oil firstly then pour new oil

8. Check the bolts regularly and assure they are not loosening;

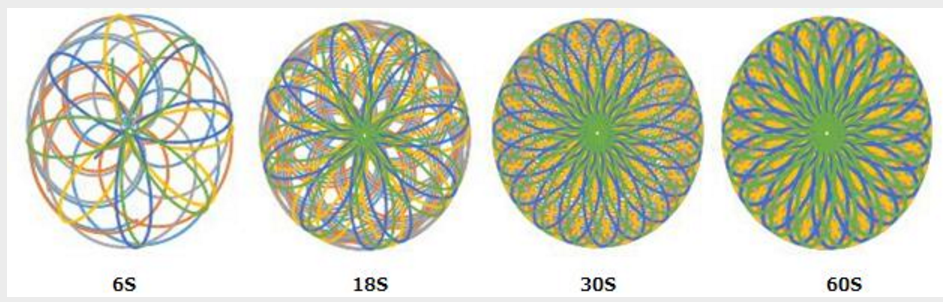

Principle of Motion: Mixing with no hidden corners in the mixing pan by installing mixing tools and

scraper tools on a specially designed drive system. The mixing track as follows.

| Technical Data | ||||||||||||||

| PMC50 | PMC 100 | PMC 150 | PMC 250 | PMC 330 | PMC 500 | PMC 750 | PMC 1000 | PMC 1500 | PMC 2000 | PMC 2500 | PMC 3000 | PMC 4000 | PMC 4500 | |

| Output capacity(L) | 50 | 100 | 150 | 250 | 330 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 4500 |

| Input capacity(L) | 75 | 225 | 375 | 500 | 750 | 1125 | 1500 | 2250 | 3000 | 3750 | 4500 | 6000 | 6750 | |

| Input capacity(kg) | 120 | 360 | 600 | 800 | 1200 | 1800 | 2400 | 3600 | 4800 | 6000 | 7200 | 9600 | 10800 | |

| Diameter of Mixing Tank(mm) | 1300 | 1540 | 1900 | 2192 | 2496 | 2796 | 3100 | 3400 | 3400 | |||||

| Mixing Power kw | 3 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 55 | 75 | 90 | 110 | 160 | 200 |

| Blade QTY | 1/2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*3 | 2*2 | 2*2 | 3*2 | 3/6 | 3/9 | 3/9 | 3/9 |

| Side Scraper QTY | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Bottom Scraper QTY | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 |

| Weight(kg) | 700 | 1000 | 1200 | 1700 | 2000 | 3500 | 6000 | 7000 | 8500 | 10500 | 11000 | 16000 | 18000 | |