QINGDAO CUISHI PLASTIC MACHINERY CO.,LTD |

|

Verified Suppliers

|

|

1. Application Hot water supply

2. Siemens 1200 PLC computer control

3. Pipe diameter: 20mm-63mm

4. Speed: 5-25m/min

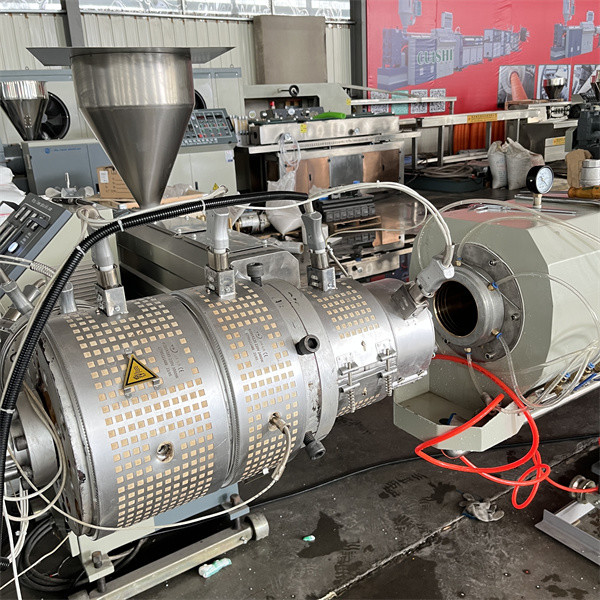

The Multilayer plastic Pipe making machine can make the pipe layer(AB/ABA/ABC/ABCA)

main components includes: Main Extruder, Co-Extruder, Marking line

Extruder, Die head mould, Vacuum calibrating tank, Water cooling

tank, haul off machine, Cutting machine, Electrical cabinet

1 | Production scope | 20mm-63mm |

2 | Production speed | 12-25m/min |

3 | Inverter | ABB/delta Brand |

4 | Electric power | 380V 50 HZ |

5 | Water supply temperature | 5-15℃ |

6 | Air pressure required | ≥0.6Mpa |

7 | Production Line Size | 38m×4m×3.5m |

8 | Low-voltage apparatus | Schneider Brand |

9 | Nominal Power | 100kw |

10 | Actual power | 70-80% |

HDPE Pipe Application:

Agricultural Irrigation water supply&Sweage drainage

pipe&Discharge system&Gas system&Architectural water

supply.

Production Flow of Pipe Production Line:

Material →Color Mixer →Automatic Feeder→Hopper Dryer →Single Screw

Extruder →Extrusion Mould & Calibrator → Vacuum Calibration

Cooling Tank → Spray Cooling Tank →Printer → Haul-off Unit →Cutter

→Stacker or Coiler

Features of Pipe Machiner:

1- 25-30m/min of maximum lineal extrusion speed, big capacity and

low power consumption, and achieved multi- layers co extrusion with

1-5 layers.

2- The copper bush is more wear-resisting and prevent material

leakage which can guarantee a stable running of extruder.

3- Material feed via spiral groove, efficient transmission and can

effectively reduce back-pressure on extruder.

4- Unique design (barrier, shearing and mixing zone) guarantees a

uniformed plasticizing effect, and can reduce the pressure on the

screw which guarantees a high speed and stable output capacity.

5- High torque gear box has a smart figuration, compact

construction, low noise, high carrying capacity, high transmission

efficiency can assure long-time trouble-free operation;

6- pipe air cooling system of die head largely increase the

extrusion speed and decrease the cooling length of extrusion line,

and improve quality of inner pipe surface;

7- Intelligent PLC controlling system with human-friendly interface

make the operation easily and conveniently;

8- Chip-free cutter ensuing flat and smooth cutting surface of

pipe.