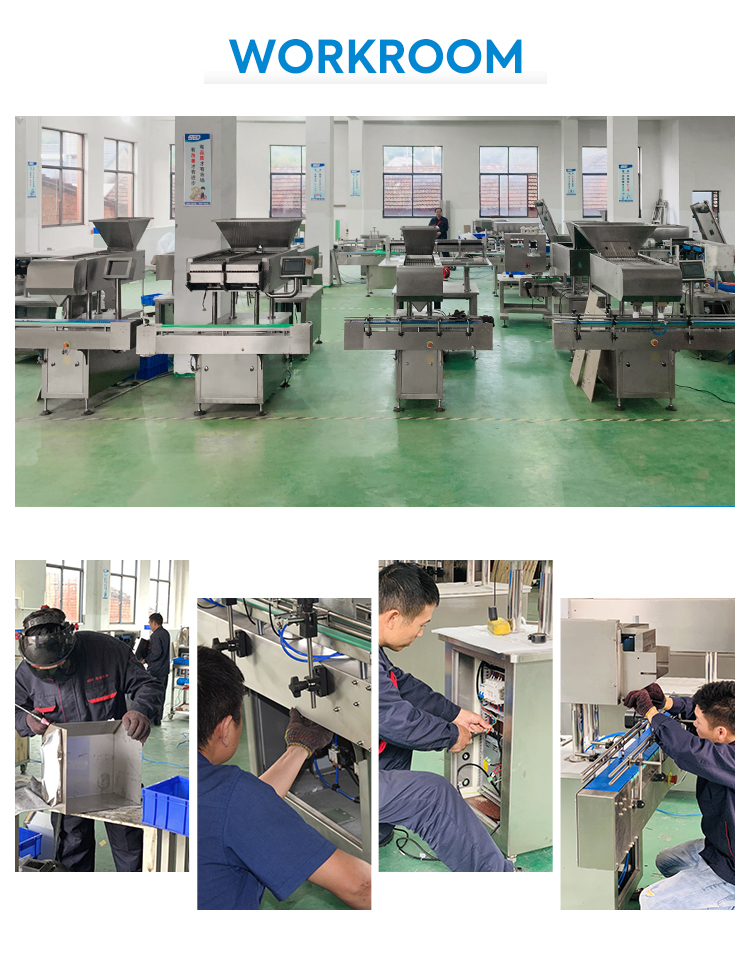

Hangzhou SED Pharmaceutical Machinery Co.,Ltd. |

|

Verified Suppliers

|

|

Automatic Rubber Stopper And Aluminum Cap Washing Machine 20000 Pcs/batch

Product Overview of Stopper Washing Machine

The automatic rubber stopper and aluminum cap cleaning machine is a special equipment required for the production of the pharmaceutical industry. It is used for washing, drying and sterilizing the rubber stoppers and aluminum caps required for powder injection, freeze-dried powder injection, water injection, oral liquid, large infusion, etc.

This machine is used to clean and remove dirt and impurities on the surface of rubber stoppers and aluminum caps, kill bacteria, and ensure the safety of drug production.

Product Parameters of Stopper Washing Machine

Model | SED-2YX-M |

Product Specifications | 240L |

Capacity | 20000pcs/batch |

Spindle speed | 0.5~8r/min |

Total power | 17kw |

Washing temperature | 40~60℃ |

Total time | 3-4h |

Dimension (L*W*H) | 2000×1530×1950mm |

Weight | 1800kg |

Feature of Stopper Washing Machine

1)Advanced washing methods, reasonable structural layout, reliable material quality, and exquisite processing technology;

2)The material, surface finish, rounded transition, process

pipeline welding and installation of the equipment are in full

compliance with GMP standards;

3)All technological processes are continuously completed in the

equipment, with easy operation, thorough cleaning and complete

sterilization;

4)The external drive of the cleaning drum, the combination of

special alloy steel mechanical seal and sanitary soft material

seal, prevent pollution and leakage;

5)Fully enclosed discharge system of CIP and SIP;

6)All original solenoid valves are changed to pneumatic diaphragm

valves to reduce noise and prolong service life;

7)All components are imported and brand products to ensure

long-term stable and trouble-free operation of the equipment;

8)PLC control; color LCD screen real-time display system working

status, online monitoring, detection and control;

9)The control system has the functions of electronic signature and

electronic record, and implements three-level password authority

management.

Show of Stopper Washing Machine