Hangzhou SED Pharmaceutical Machinery Co.,Ltd. |

|

Verified Suppliers

|

|

SED-250DG Low Temperature Customisable Freeze Dried Fruit Machine High Performance Power 380V/50HZ,3Phase,5Wire

Product Description of Freeze Dry Machine

Freeze-dry (brief named Freeze-dry) is a stable process of material

dried which will put the material contained with water to freeze to

solid first, then make among them of the water sublimate from solid

to air condition, removing water to preserve materials.

Products at solution stage are frozen through sublimation and

desorption, then the solvent reduce to a certain extent, thereby

preventing the formation of micro-organisms or chemical reaction

between the solute and solvent that products can be preserved for a

long time and maintained its nature.

Vacuum freeze-drying method is a liquid solid gaseous process. In

freeze-drying process, "liquid bridge" between the solution

particles has been frozen into "solid bridge".

The relative position of particles has been fixed and does not

exist surface tension on gas-liquid interface between the two

particles. With the continuous distillation of solvent, "solid

bridge" continuously decrease, but the the relative position

between two particles will no longer change until the "solid

bridge" completely disappear.

Product Parameters of Freeze Dry Machine

| Power | 380(1±5%)V,50Hz,3Phase,5Wire |

| Power consumption | Around 33kw |

| Cooling water qty | ≥11m3/h(T≤30℃/P=0.15-0.2Mpa) |

| Compressed air | ≥0.1m3/min (P=0.5-0.8Mpa) |

| Steam consumption (sterilization) | ≥100Kg/h(P=0.2-0.3Mpa) |

| Structure | Integral(Rectangular box dry +Mushroom valve+Rectangular cold trap) |

| Steam consumption (Defrost) | 25Kg/batch(pressure≥0.2-0.3MPa) |

| Chamber design pressure | 0.16mbar/-0.1 mbar |

| Chamber design temperature | 130℃ |

| Chamber Vacuum leak rate | 0.005 Pa.m3/sec |

| Total usable area of shelves | 5.67 ㎡ |

| Maximum water fishing | ≥120Kg/batch |

| Temperature of lamellar | Highest temperature of shelf ≤+80℃ |

| Shelf heating rate (no load) | -40℃→20℃≤60min |

| The number of shelf | 7+1 (Compensation Board) |

| Shelf spacing | 90mm |

| Shelf dimensions | 900*900mm |

| Cabinet design pressure | 0.16 Mpa /-0.1Mpa |

| Tank design temperature | 130℃ |

| Machine size (L×W×H) | 5000×2000×3100mm Final dimension based on design |

| Total weight | 5000kg(Approx.) |

| Model Num. | SED-2DG |

Feature of Freeze Dry Machine

1. Stainless steel is polished with excellent brand to ensure

surface roughness to ensure sterility requirements

2. 3D design, consistent with CGMP requirements of complete sterilization.

3. Special section of the door seal to avoid water retention in the

CIP / SIP process

4. Cabinet, board level, and hose are tested after multiple

procedures to ensure without leakage

5. Liquid level sensing probe and preventing intrusion device are

installed on outfall water

6. Mushroom valve ball surface is smooth and easy to clean;

7. Mushroom valve can be adjusted through the valve closed, to

prevent excessive pressure

8. Mushroom valve in the "open" or "off" with the feedback signal,

can understand the working state real

9. Plate flange of mushroom valve processed two times with high

sealing performance and accuracy, can completely prevent leakage .

Product Show of Freeze Dry Machine

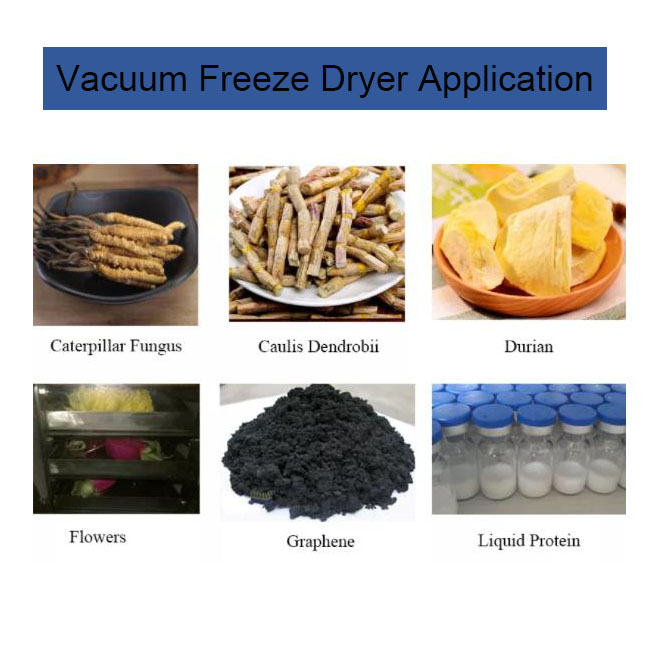

Application of Freeze Dry Machine

Food freeze dryer can freeze-dry pet food, cat food, dog food, chicken breast, quail, cosmetics, liquid and other products. It is produced under low temperature and vacuum conditions. Under such production conditions, it is easy to oxidize, volatile, Heat-sensitive substances can be preserved, and the harmful effects of bacteria and enzymes can be inhibited.