Hangzhou SED Pharmaceutical Machinery Co.,Ltd. |

|

Verified Suppliers

|

|

Product description of Capsule Filling Machine

Our capsule-filling machine is used to encapsulate product (powder,

and pellets) in gelatin capsules. Empty capsules are loaded into

the capsule hopper where they are fed into the magazine. Capsules

initially enter the magazine un-oriented. From the magazine, the

capsules enter the sorting block where they are properly oriented

(smaller end on the bottom). The capsules are then separated by

vacuum. The lower portion of the capsule is filled. The upper

portion of the capsule is inspected to ensure the capsule is

separated. (If the capsule is not separated or is faulty, a pin

will dislodge the capsule and the vacuum will remove it from the

system.) The two halves are then joined together. The finished

capsule is discharged to a chute and the station is cleaned with an

air blast.

The capsule filler can use all makes of capsules (00#~5# and safety

capsule A~E). Non-separated or improperly inserted capsules will be

automatically rejected. Capsule target fill weight can be adjusted

by changing dosing disks. At the end of a run, only a small

quantity of product will be remaining in the hopper.

Main Parameter of Capsule Filling Machine

| Equipment Model | SED-420J-I E |

| Machine weight | 800kg |

| Overall dimension | 810 ×945× (1930+150) mm |

| Motor power | 1.92kw + 2.2kw (Dust Collector) |

| Power supply | 3 phase, AC 380V, 50Hz |

| Max. Output | 25,200caps/hr |

| Number of holes | 3 hole |

| Capsule size | 00#~5# and safety capsule A~E |

| Capsule using rate | ≥ 99.5% |

| Noise index | ≤ 75dBA |

| Dosage difference | ≤ ±3% (under more than 300mg dosing and 40~80 mesh after granulation) |

| Water supply | Water cycle pump compound water tank, or meet water source |

| Vacuum degree | -0.02~-0.06MPa |

compressed air (for cleaning station) | air consumption 3m3/h pressure 0.3~0.4Mpa |

| Water volume | 250L/hour |

| Enter pipe inner-diameter | 20mm |

| Waterspout inner-diameter | 27mm |

| Working temperature | 21℃ ± 3℃ |

| Working relative humidity | 40~55% |

| Exhaust capacity | 270m3/h |

| Special function | Pellets, powder mixed; powder collected recycle |

| Control system | Stepless frequency conversion control, PLC control, touch-screen tablet computer, be provide with OPC Server, Industrial Ethernet Interface be connected with OPC Client, be realized with FDA CFR211 e-signature and e-recording. |

| Material | Spare part contact with medicine adopt superior S.S 304 & GMP compliable material |

| Criterion | Comply to CGMP & FDA |

Features:

Product Details

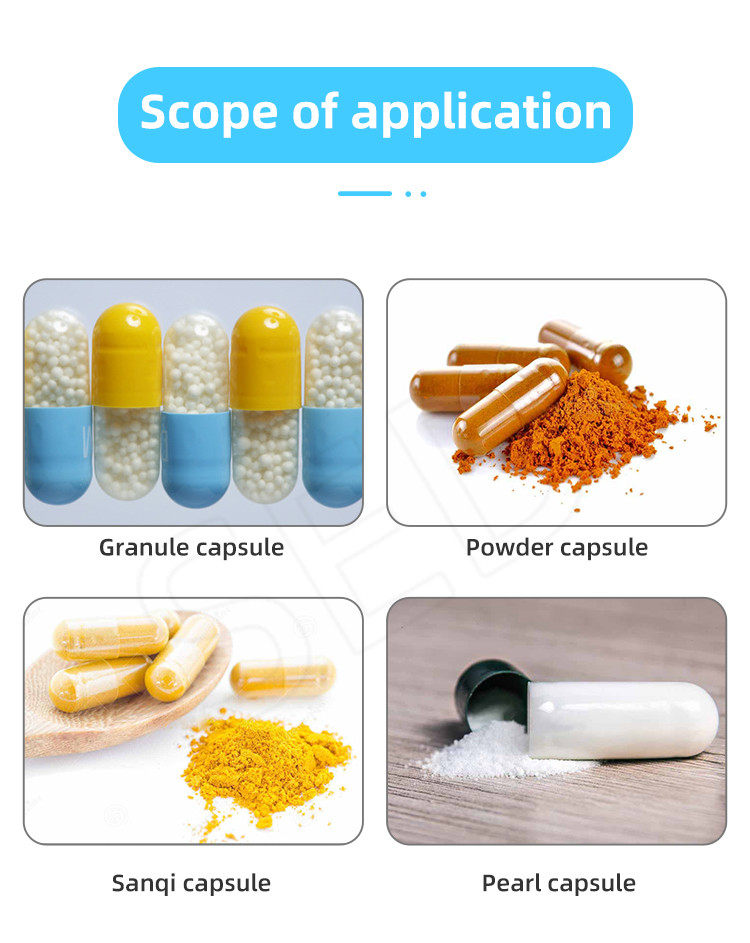

Application of Capsule Filling Machine

Machine complete with: