Jiangsu Hualian Yiming Machinery Co.,Ltd. |

|

Full Automatic Four Side Seal Packaging Machine / Sachet Filling Equipment

DXDO-J900E ketchup Double Film four side sealing & multi-line packing machine

1) Easy to adjust, precise in measurement, requires a simple

procedure for pouch length adjustment without changing the mould.

Functions can be regulated for longitudinal sealing, transverse

sealing, filling, notch cutting, longitudinal cutting, fracture

line making and transverse cutting with the advanced technology for

our man-machine interface.

2) Famous servo motor driver is adopted, high-performance PLC pouch

length can be setup directly at the touch screen, at the same time

longitudinal sealing and transverse sealing be able to auto

in-phase tracking. It saves more time and material compare with

mechanical transmission, and with bag pulling smoother and even

easier to adjust.

3) Accuracy in page correcting, automatic counting, and

photoelectric tracking system is adopted to ensure the automatic

correcting the double face printing design on packing bags, precise

in counting.

4) It has reliable performance, convenient to operate and super

automatic. A PLC is used for automatic controlling.

5) Applicable to a wide using: suitable for most of the complex

film packing materials.

Usage:

It is suitable to pack ketchup materials in the fields of pharmacy

industry, food industry and daily industry. Such as ketchup,

shampoo, honey, mayonnaise, jam, cream of all kinds.

Main technological parameter :

| Bag length | 50-300mm(L) (adjustable) |

| Bag width | 35-100mm(W)fix and can’t change |

| Packing speed | 45bags/min (8lines) depend on pouch size and material |

| Measuring range | 2-100ml |

| Cutting fashion | Flat cutting, with tear notch |

| Sealing fashion | 4 side sealing |

| Applicable film | PET/AL/PE PET/PE NY/AL/PE NY/PE |

| Max width of film roll | 450mm |

| Max film roll diameter | Φ300mm |

| Film roll core diameter | Φ75 mm |

| Power voltage | 380V/ 3 phase 4 wires 50HZ |

| Power | 12KW |

| Package size | (L)1400mm×(W)2800mm×(H)2000mm |

| G.W | 1500KG |

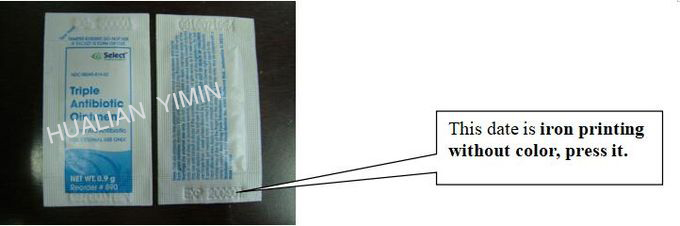

samples:

REMARK:

Dxdo-k900e four side sealing multi-row granule packing machine is

suitable for packing loose and non-sticky granule materials, such

as: pellets, sugar, salt, soup, cereal, seeds, coffee, infusion,

etc. · high energy, high intensity, low noise, compact structure,

smooth operation, convenient maintenance, long service life. · drum

heat sealing, four-side sealing, high speed multiple bag packaging,

and the bag type is smooth and exquisite, high packaging

efficiency. · simple adjustment and measurement **, stepless

adjustment of bag length can be carried out without changing molds,

and the actuator such as vertical seal, horizontal seal, filling

and feeding, batch number, tearing mouth, vertical cutting,

fracture line and crosscutting can be adjusted through man-machine

interface. · accurate and automatic counting of printing patterns

on both sides of packaging bags. Photoelectric tracking system is

adopted to ensure automatic alignment and accurate counting. ·

reliable performance, convenient operation, high level of

automation, the whole machine adopts PLC automatic control,

frequency conversion stepless speed regulation. · strong

applicability, the domestic production of composite film packaging

materials can be used.