ALLIANCE MACHINERY (SHANGHAI) CO., LTD. |

|

NJP400 Automatic Capsule Filling Machine Filling Pellet Granules Vacuum Loader 24,000

NJP400

Description:

After the machine is started, the capsules in the capsule hopper will enter the selection fork of the dispensing device one by one. By the action of the directional push-out and the selection fork, each capsule is loaded into the hole of the first station module in the downward direction of the upper body, and the vacuum separation system separates the body and the cap of the capsule. The second station reserves a buffering station for the sheave. In the third station, the upper module rises and is separated from the lower module. A filling device at the fourth station pushes the compacted pellet into the capsule. The fifth station also reserves a buffer station for the sheave. At the sixth station, the capsules in the module and the caps that are not separated will be cleaned up. The seventh station still reserves a buffering station for the sheave. In the eighth station, the module is retracted and merged with the upper module, and the capsule of the filling material is locked and locked by the push rod to achieve the finished product requirement. At the ninth station, the finished capsules will be pushed out by the putter. At the tenth station, the cleaning unit cleans the module for the next cycle.

Features:

1. Based on the lower plane of the metering disc, the three-dimensional adjustment mechanism eliminates the natural deformation of the dose plate and the copper pad. The gap is uniform, the powder leakage phenomenon is reduced, the cleaning is convenient and guaranteed, and the difference in the capacity is the same.

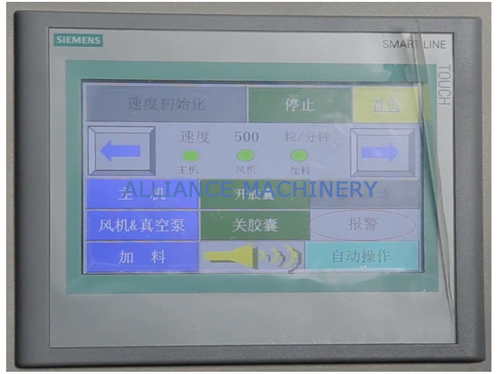

2. Capsule switch

5. Jog system

Options:

Pellet/granules filling device

Auto empty capsule vacuum loader

Auto power transporter

Capsule letter/logo printing machine

Specifications:

| Model | NJP400 |

| Output [Capsules/min] | 400 |

| No. of segment bores | 3 |

| Suitable for capsule | 00#-5# |

| Total power [kW] | 3 |

| Overall weight [kg] | 800 |

| Overall dimensions [mm] | 760 x 780 x 1900 |