Leadtop Pharmaceutical Machinery |

|

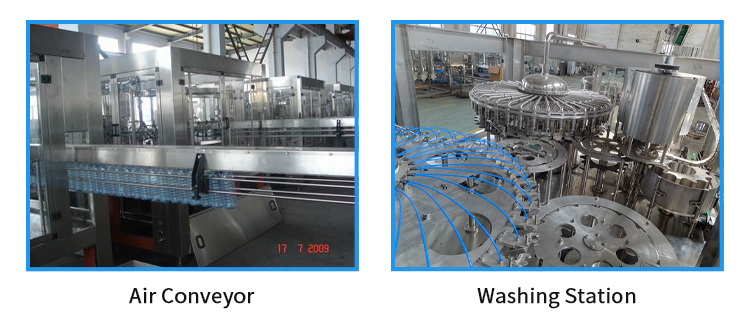

This unit is a combined multi-functional unit that integrates washing, filling and capping. It is one of the most ideal small and medium-sized beverage machinery equipment in China. The whole machine adopts advanced man-machine interface operation, PLC control, variable frequency stepless speed regulation and other automatic control technology. It has automatic shutdown at low temperature, automatic control of feeding and returning, with no bottle and no cover, bottle waiting, bottle bottle stop, The cover is automatically closed when the cover is not closed.

Four Part Of Machine:

1.Washing Part,

2.Filling part,

3.Capping part

4.Star wheel part.

The height of the bottle washing machine ,filling machine and cap

screwing machine has been adjusted before they are carried out of

the factory. They can suitable for different sizes bottles in the

designing scale. Empty bottles are conveyed to the bottle washing

machine with air conveying system through bottle entering spider

.The bottle will turn up 180o ---washing bottle ----dropping water

–bottle turn up 180o ,the bottle mouth is upward .The bottle is

carried to the filling machine through transferring spider and

settle down at the part of bayonet of bottle mouth of the filling

machine. .And it switches with the filling valve. If there is a

bottle ,the filling begins .If there is not a bottle , the valve

closes. After the filling ends, the filled bottle is carried to the

cap screwing machine through the transferring spider of the work

table of the cap screwing machine .The capped bottle is conveyed to

the next process (equipment) with the bottle exiting spider through

the exhaust bottle belt.

Technical parameters:

Machine Details: