Dongguan Chuangwei Electronic Equipment Manufactory |

|

Verified Suppliers

|

|

Stress Free Depaneling with 18W UV Laser Head without Tooling Cost

Stress Free Depaneling:

Utilizing a laser for the depaneling process means cutting is achieved with-out making contact with the PCB. Cutting without contact means there is no stress to the PCB or to the decliate components on that PCB.

No stress to the PCB or components ensures there are no failures due to stress cracks resulting in increased quality and performance of end products.

The stationary laser assembly guarantees a cut that is consistently accurate. The focal point of the beam will not move and the laser accuracy never degrades with machine and motor wear.

Laser routing provides significant dust reduction over traditional cutting with a router bit or a saw.

Significant dust reduction means there is no secondary process step required to remove dust left by the depaneling process.

No dust means no foreign material on the PCB or end product that can cause failures or contamination.

The dual shuttle in-feed provides speed, flexibility and accuracy. It provides the ability to run one PCB very fast or the flexibility to run two different programs simultaneously. The cycle time is less than 2 seconds for the PCB shuttle process. Running two products simultaneously reudces changeover time to zero.

Every machine movemnt is extremely fast and accurate due to all axes using high precision linear motor technology.

Specification:

| Laser | Q-Switched diode-pumped all solid-state UV laser |

| Laser Wavelength | 355nm |

| Laser Power | 10W/12W/15W/18W@30KHz |

| Positioning Precision of Worktable of Linear Motor | ±2μm |

| Repetition Precision of Worktable of Linear Motor | ±1μm |

| Effective Working Field | 400mmX300mm(Customizable) |

| Laser Scanning Speed | 2500mm/s (max) |

| Galvanometer Working Field Per One Process | 40mmх40mm |

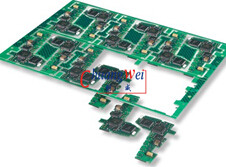

Application: