Dongguan Chuangwei Electronic Equipment Manufactory |

|

Verified Suppliers

|

|

Automated Optical Inspection Systems with Germany Camera,SMT LED Inspection Machine

Feature:

2. Various vector image algorithms to get the best inspection capability

The vector image algorithms include logic operation ,distance of luminance boundary, chiptracing,OCR/OCB Luminance/color template matching, colordistance, colordistance, color extraction (RGB&HSV),VALUE-range of luminance offset of luminance, the minimum variation span of luminace,etc……More than 30 Kinds of the most advanced algorithms

3. Germany imported 5.0 MP Industry cameras

Wight a high-color reproduction, collocation a high-resolutiontelecentriclens, high NG identification, provide high-definition image output the AOI

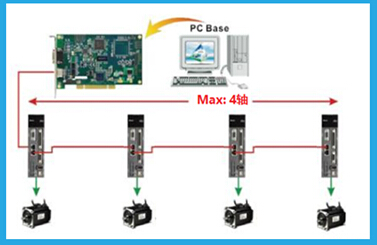

4. Control system

All major components are used internationally renowned brands, in the premise of ensuring the stability and accuracy of the movement equipment with high service life and low failure rate.

5. The entire PCB match capability can detect extra part at any location

6. Multi machines one operator, intelligent communication

Central server mode that gathers information from all the test machines to facilitate the integrated management of production, multiple machines need only one operator