Shenzhen Yingsheng Technology Co., Ltd. |

|

Verified Suppliers

|

|

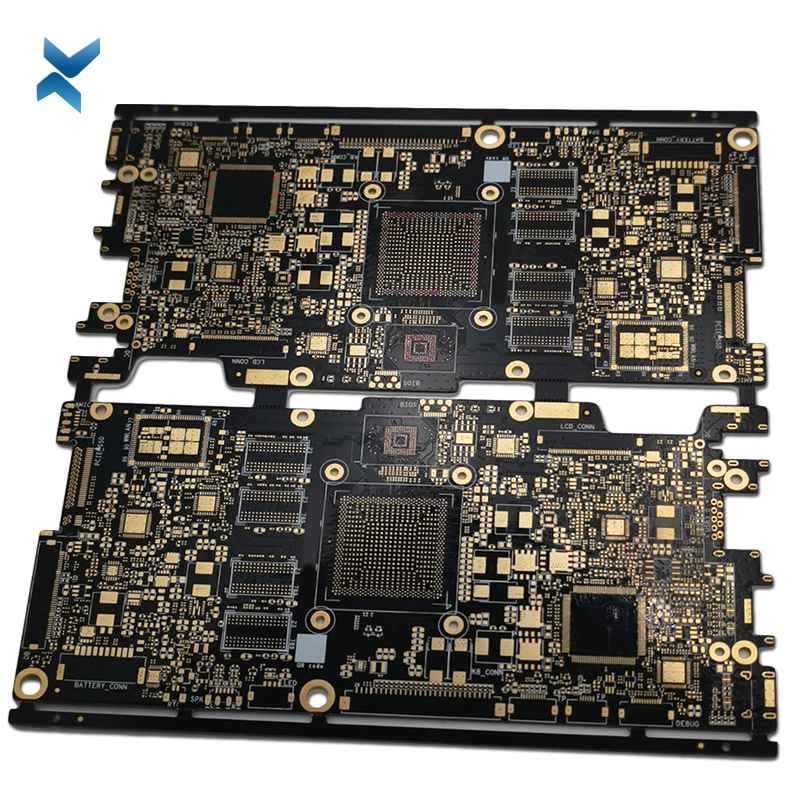

High-Quality Pcb Circuit Board Isola Pcb Need Customer Gerber File

Isola 370HR Features

The core material is available in sheet structures and regular

boards.

It is viable with lead-free coupling and FR-4 processing.

Its standard thickness is between 0.05 mm (0.002cm) and 3.5 mm

(0.125cm).

The product is eco-friendly and compliant with RoHS.

The prefabricated structure is in a board or roll structure.

CAF Resistant.

Glass fabric is available.

Dielectric properties and thermal resistance make this board great

for high-temperature applications.

The decomposition temperature (Td) is high.

Likewise, it has an extremely high glass change temperature (Tg).

Blocks UV rays.

The CTE has a low Z-axis.

| Isola | 370HR |

| FR408HR | |

| IS680-300 | |

| FR406 | |

| IS620i | |

| IS410 | |

| P95/P25 | |

| GreenSpeed | |

| P96/P26 | |

| GETEK | |

| G200 |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

About ISOLA 370HR

ISOLA 370HR is a high performance 180°C glass transition

temperature

(Tg) FR-4 system for multilayer Printed Wiring Board (PWB)

applications where maximum thermal performance and reliability are

required.

If you want to find other high frequency PCB material .

You come to right place, Dupont PCB, Arlon PCB , Rogers PCB,Teflon PCB. etc.

Normally we have material in stock , If special Part number, We can buy material for you .

Donot wait anymore, send inquiry to sales@yscircuit.com , YScircuit will be your good PCB Manufacturer.

Have you been hoping to learn about Isola PCB?

Here we will be revealing to you everything possible about Isola PCB.

These include its uses, properties, features, quality testing, laminate material, quality certification, and more.

Please continue reading to become an Isola PCB expert.

1. What does Isola PCB Mean?

This printed circuit board is complex and fabricated making use of

high-performance laminate materials.

It integrates resin constituents that are engineered in order to meet performance requirements that are demanding.

This PCB type is used in the majority of electronic equipment such as aerospace equipment and high-grade consumer electronics.

2. Types of Materials Used in Isola PCB

There are materials used in making Isola PCB. Some of them include

Prepreg

This term is associated with the PCB industry.

It is referred to as “previously impregnated.”

This is a dielectric material that offers electrical insulation, as well as other great features.

It is manufactured via fiberglass fabric infusion with resins that are uniquely formulated.

The resin incorporates distinct thermal, electrical, and physical features to the prepreg.

It is important in correcting the operation of the Isola PCB.

Copper Clad Laminates

This is made up of a prepreg laminated layer found on the two ends

that have a thin layer of copper foil.

This lamination is achieved by compressing one or more copper and prepreg plies together under extreme heat, pressure, and vacuum conditions.

3. Constructing the Multilayer Isola PCB

Prepreg and CCL are utilized in fabricating multilayered Isola PCBs via complex operations that involve multiple processes that are usually repeated.

The copper surfaces of the laminate are etched.

This is to produce electronic circuits. Going forwards, assemble the laminates to form a multilayer structure via inserting one or more prepreg plies between each etched laminate.

Plating and holes drilling then follows the creation of electrical interconnections among PCB layers.

The Isola PCB that results is an interconnection gadget, where semiconductors and other parts are mounted.

Isola PCB Applications

The laminate and prepreg materials of Isola PCB can be applied in different equipment and advanced electronic which includes:

4. What Material is used in Making Isola PCB’s Resin System?

Isola PCB makes use of no-flow prepregs, which are polyimide-based

for PCB applications requiring high temperatures.

They make use of a polyimide, retardant resin system, which is great for applications requiring superior performance and thermal properties.

The prepreg materials of the Isola apply a polyimide blend and thermoplastic resin, which are fully cured without making use of Methylenedianiline (MDA).

This then leads to polymers that have a high Tg, which lacks the problems of brittleness and low initial bond strength.

Therefore the resin system of Isola PCB is much better compared to the resin structure of conventional thermoset polyimide.

5. Features of the Isola Prepreg Materials

Below are some of the major features of the materials of Isola PCB:

6. What Laminate Materials are Utilized in Isola PCB

Now, let’s consider some common laminate materials that can be used

when manufacturing Isola PCBs:

Astra MT77

This laminate material of Isola PCB has great electrical features

that are steady over a wide range of frequency and temperature.

It has a steady dielectric constant that falls within the range of -40 degrees Celsius and +140 degrees Celsius.

In addition Isola Astra MT77 offers a dissipation factor of 0.0017, which is very low.

This is why it is a less expensive alternative to PTFE, as well as other commercial microwave laminate materials for PCB.

This laminate material is great for a good number of today’s RF/microwave PCB designs.

DE104

The DE104 offers a great thermal resistance due to a low CTE and a

great unique resin system in the Z-axis.

DE104 also comes with a decomposition and glass temperature of 315 and 135 degrees Celsius respectively.

The laminate time for it to delaminate at a temperature of 260 degrees is 12 minutes.

This material may be processed using ordinary parameters and is usually catalogued as FR-4.

ED130UV

The epoxy laminate of ED130UV allows you to meet the specifications

necessary for PCB construction making use of UV blocking materials.

These Isola PCB laminates utilize an epoxy resin base that has

advanced epoxy face plies.

The ED130UV goes a long way in UV fluorescence and blocking if making use of Automated Optical Inspection.

FR402

This is made up of tetrafunctional epoxy resin, which is made for

applications requiring multilayer Isola PCB, which requires

performance properties that surpass difunctional epoxies.

The FR402 formulation came to be to improve accuracy, as well as throughput AOI devices that are laser-based. Asides from this, it offers great resistance to chemical and thermal degradation.

FR406

This Isola PCB laminate forms the benchmark of the industry for

high performance materials of epoxy PCBs.

This is designed to meet the multilayer PCB specifications, while ensuring that the conventional FR-4 processing is retained.

The FR406 offers great chemical and thermal performance, product consistency, and enhanced dimensional control.

FR408

The Isola FR408 is a type of high-performance epoxy PCB laminate

and prepreg, which is designed to ensure improved PCB applications.

It features a low dielectric constant and dissipation factor.

This is why they are great for broadband PCB designs that require faster signal speeds or enhanced signal integrity.

This Isola PCB material works fine with most FR-4 processes.

With this property, you’ll be able to utilize FR408 minus integrating complexity to the fabrication methods used today.

FR408HR

This Isola material is a high-performance one with a temperature of

230 degrees Celsius.

This FR-4 system is great for multilayer PCB applications requiring optimal thermal performance and reliability.

The Isola FR408HR laminate materials and prepreg are fabricated making use of the copyrighted multifunctional resin complex, which are strengthened using E-glass fabric.

With its great resistance to moisture during reflow, as well as other great features, this forms a product, which closes the void from the thermal and electrical perspective.

This Isola PCB material also offers UV blocking and laser fluorescing to ensure maximal compatibility with:

Another material used is Isola tachyon material.

7. What are the Quality Certifications for Isola PCB?

The major quality standards where the best Isola PCB materials

ought to work with include:

8. Which is Better: Isola PCB vs. Nelco PCB?

When it comes to performance, Nelco PCB is better.

This is because Nelco PCB offers both superior thermal and mechanical performance.

Asides from this, all the materials of Nelco PCB comply with the RoHS standards, and majority of them offer high thermal dependability.

This makes them work with lead-free assembly. Asides from this, Nelco PCB materials come in several types.

9. What Differentiates the Isola 185HR and 370HR?

The laminate and prepreg materials of the 185HR Isola PCB are made

using the copyrighted technology of Isola, and strengthened with

the use of E-glass (electrical grade glass) fabric.

This system provides a lesser Z-axis expansion, 340 degree Celsius decomposition temperature and reduced loss when comparing it with competitors.

Moreover, the system of the Isola 185HR is laser fluorescence and UV blocking. This ensures maximum feasibility with:

The laminates and prepregs of 370HR Isola PCB, on the other hand are produced utilizing the high performance FR-4 epoxy resin complex.

The Isola 370HR material was put together for multilayer PCB and its glass transition temperature is 180 degree Celsius.

This temperature is great for applications that require optimal thermal performance and spectacular CAF resistance.

This system offers moisture, mechanical, and chemical resistance, which are equivalent to do better than the performance of normal FR-4 materials.

Asides from this, in serial lamination designs, the 370HR has proved its ease of processing and great performance.

10. What is the Rheology in Isola PCB Fabrication?

When manufacturing printed circuit boards, the study of the flow of

material when it is subjected to heat and pressure is referred to

as Rheology. This allows users to characterize the viscosity of a

material as a function of temperature, heat rise rate, applied

shear, and other factors.

This lets users obtain press lamination-related data. The standard model used in describing PCB materials’ Rheology deals with two parallel plates that have material to be designated placed in the middle.

From the pattern, one of the plates drifts to the other in a parallel way.

11. Conclusion

By now, you should have gained wide knowledge about Isola PCB.

This printed circuit board is a complex one, which is fabricated making use of high-performance laminate materials.

This PCB type is used in the majority of electronic equipment such as aerospace equipment and high-grade consumer electronics.

12. Are you still looking for an pcb manufacturer for Isola material?

Don’t wait anymore, send enquiry and questions to info@yscircuit.com.

YScircuit will be your good PCB Manufacturer and Consultant.