Shenzhen Yingsheng Technology Co., Ltd. |

|

Verified Suppliers

|

|

Lighting Product Circuit Boards Flexible Pcb Boards For LED Light

What is Flexible PCB?

Flexible PCBs, also known as flex circuits or flexible printed circuit boards, are electronic interconnection components.

They are made of a thin insulating polymer film with conductive circuit patterns attached to it.

These circuits are often coated with a protective polymer layer.

Flexible PCB technology has been used for connecting electronic devices since the 1950s and is now a crucial technology for manufacturing advanced electronic products.

In many cases, flex circuits are made of polyimide or a similar polymer.

This material dissipates heat better than most rigid circuit board materials.

For this reason, flexible circuits can be placed in inconvenient locations where heat would impact the performance of a rigid circuit board.

Flexible circuit boards can be designed to withstand extreme temperatures – between -200° C and 400° C – which explains why they are so desirable for borehole measurements in the oil and gas industry.

In fact, because of these conditions, and the need for small, unobtrusive devices in most industrial environments, flexible circuits represent the first choice for engineering design in most industrial sensor technologies.

High-temperature resistance comes usually comes with good chemical resistance and excellent resistance to radiation and UV exposure as well. Combined with the ability to control impedances in high-density circuit board designs, flexible circuit designs offer many benefits to manufacturers.

The flex pcb raw material and stack up will decide the flex circuit quality.

According to the market demand, there are three types of base raw material used for Flexible circuit board. Poyester(PET), adhesive Polymide (PI) and adhesiveless Polymide (PI) .

Do you know the difference between the PET and PI material?

If not, let us learn about it together now.

The advantages and disadvantages of Polyester(PET) and Polymide(PI).

The advantages of PET material: Production process is less, price is cheaper, lead time is shorter.

The disadvantages of PET material: Polyester material can not pass through soldering flow. Then it can not be working in high temperature environment.

The advantages of polymide (PI): It’s easy to bend. Can work in high temperature.

The disadvantages of Polymide (PI): The price of raw material is much higher than Polymide.

Flexible circuit boards are certainly useful, but they are not going to replace rigid circuit boards for all applications.

Cost efficiency is the main obstacle to implementing an exclusively flexible circuit board design in a consumer product.

Rigid circuit boards are less expensive to manufacture and install in a typical automated high-volume fabricating facility.

Typically, the ideal solution for an innovative product is one that incorporates flexible circuitry when necessary and employs solid, reliable rigid circuit boards where possible to keep manufacturing and assembly costs down.

Some manufacturers even use hybrid rigid-flex printed circuit boards expressly for this purpose.

This is common in laptop computers and medical devices, where rigid circuit boards can be connected to one other using ribbon-like flexible circuits.

These boards can be compounded and designed to meet any number of engineering needs by focusing on the respective strengths of each circuit board base technology.

YScircuit creates both flexible and printed circuit boards for product manufacturers.

Enjoy a consultation with one of our sales reps to find out if your product prototype design is best served by flexible or rigid circuit board types.

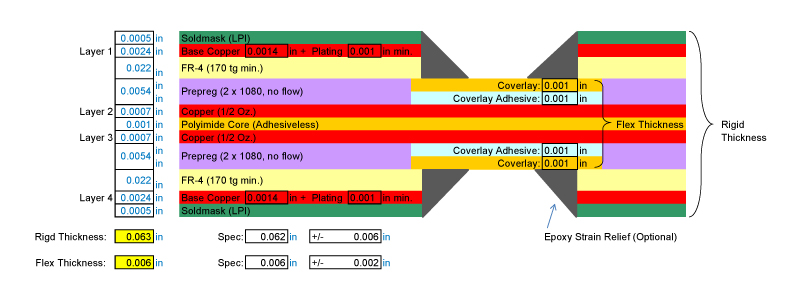

Flexible PCB stack up

| Layer | 1-8 |

| Material | DuPont PI, Domestic Shengyi PI |

| Thickness (Finished Board) | 0.05 mm-2.0 mm |

| Max. Board Size | 406 mm*610 mm |

| Copper weight (finished) | 457mm*610mm |

| Surface Finish | Hot air solder leveling (HASL) Lead-free HASL: RoHS compliant Electroless nickel/immersion gold (ENIG): RoHS compliant Immersion Tin: RoHS compliant Organic solderability Preservatives (OSP): RoHS compliant |

| Min. Tracing/Spacing | 3 mil/3 mil |

| Min. hole size—Drilling (PTH) | 0.2mil |

| Min. hole size—Punching (NPTH) | 0.5mil |

| Tolerance of dimension | +/-0.05 mm |

| Solder-stop coating—Soldermask oil | Green, red, black, yellow, white, blue |

| Solder-stop coating—Coverlay | PI and PET film |

| Silkscreen legend color | White, black, yellow |

| Peelable solder mask | Yes |

| Gold fingers | Yes |

| Stiffener | Yes, material PI or FR4 |

| layer/m² | S<1㎡ | S<3㎡ | S<6㎡ | S<10㎡ | S<13㎡ | S<16㎡ | S<20㎡ | S<30㎡ | S<40㎡ | S<50㎡ | S<65㎡ | S<85㎡ | S<100㎡ |

| 1L | 4wds | 6wds | 7wds | 7wds | 9wds | 9wds | 10wds | 10wds | 10wds | 12wds | 14wds | 15wds | 16wds |

| 2L | 4wds | 6wds | 9wds | 9wds | 11wds | 12wds | 13wds | 13wds | 15wds | 15wds | 15wds | 15wds | 18wds |

| 4L | 6wds | 8wds | 12wds | 12wds | 14wds | 14wds | 14wds | 14wds | 15wds | 20wds | 25wds | 25wds | 28wds |

| 6L | 7wds | 9wds | 13wds | 13wds | 17wds | 18wds | 20wds | 22wds | 24wds | 25wds | 26wds | 28wds | 30wds |

| 8L | 9wds | 12wds | 15wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 10L | 10wds | 13wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 12L | 10wds | 15wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 14L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

| 16L | 10wds | 16wds | 17wds | 18wds | 20wds | 20wds | 22wds | 24wds | 26wds | 27wds | 28wds | 30wds | 30wds |

FQA

Q: What express options are available?

A: We ship circuit boards with FedEX, DHL, UPS, TNT and other express options.

Q: How long does it take for the shipping?

A: Usually it takes 3-5 working days for international shipping.

Q: How much does customs clearance cost? / How much import fee should I pay for importing circuit boards?

A: Customs and duty fees vary per country and are the sole responsibility of customer upon receipt of package at customs. We can declare your products at lower value to reduce the possibilities of you being charged by high duty fees. Reach us at info@yscircuit.com to discuss details.

Q: If I want to ship two orders together, how much money can I save?

A: Please send order numbers along with the shipping address to info@yscircuit.com, we will recalculate the shipping cost according to the final weight and tell the price difference asap.