Shenzhen Hansome Technology Co., Ltd. |

|

Verified Suppliers

|

|

Automatic SMT Cleaning Equipment Rotation Condenser Cleaning For Solder Pallet

Introduction

The equipment is suitable for all kinds of the outer surface of the workpiece cleaning, such as wave soldering pallet, reflow soldering tray,condenser cleaning, printing scraper, machine parts surface flux, clean oil, dust etc. Integrated use of artifacts in the rotating basket by high pressure spray cleaning, high pressure spray rinse, high-pressure wind shear and large flow fan hot air drying technology, guarantee the cleaning effect.

Specification

| Model | HS-630 |

| Dimension | 2000*1400*1500mm |

Clean Basket diameter | 1000mm |

Part Max height | 480mm |

Basket loading | 100 KG |

Pressure scope | 3-6 KG |

Clean tank capacity | 60L |

Spraying pressure | 5-8 KG |

Recommend clean agent | Water-based clean solvent |

| Cleaning method | High pressure 360degree rotation cleaning |

Features

1. One button operation ,Automatic completes the whole cleaning process,Auto add and discharge clean and rinse liquid.

2. Integrate the function of cleaning,rinsing and drying.

3. Tooling & fixtures cleaned can be used directly to next process , the cleaning performance is perfect.

4. Spray pressure adjustable ,cleaning in 720 degree directions no blind angle.

5. High loading capacity ,saving labor.

6. High -performance rinsing and liquid circulating filtration system ,cleaning spray system in the airtight chamber ,and keep the cleaning agent life longer ,save cost.

7. Equipment running with low energy consumption, low noise, no pollution, energy save and environmental protection, the whole structure with stainless steel.

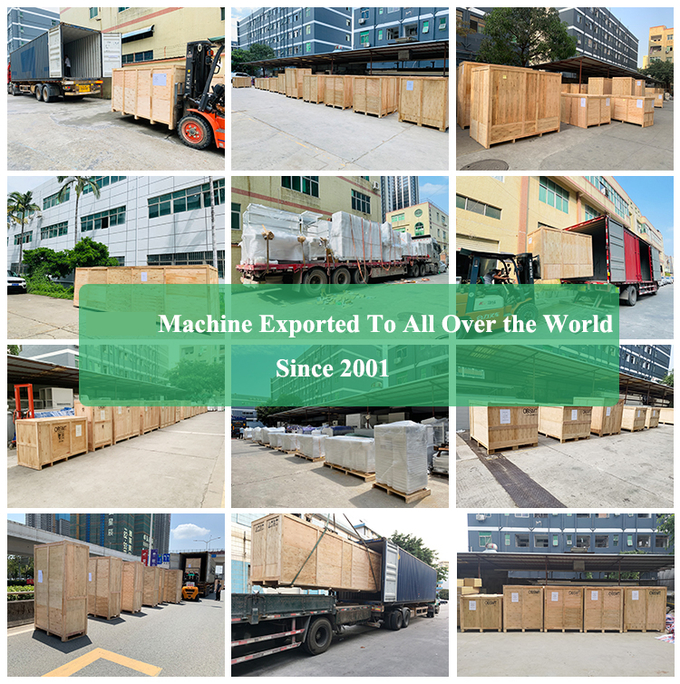

About Packaging